Tsom rau PC / PMMMA Sheet thiab kev ua jason@mclsheet.com +86-187 0196 0126

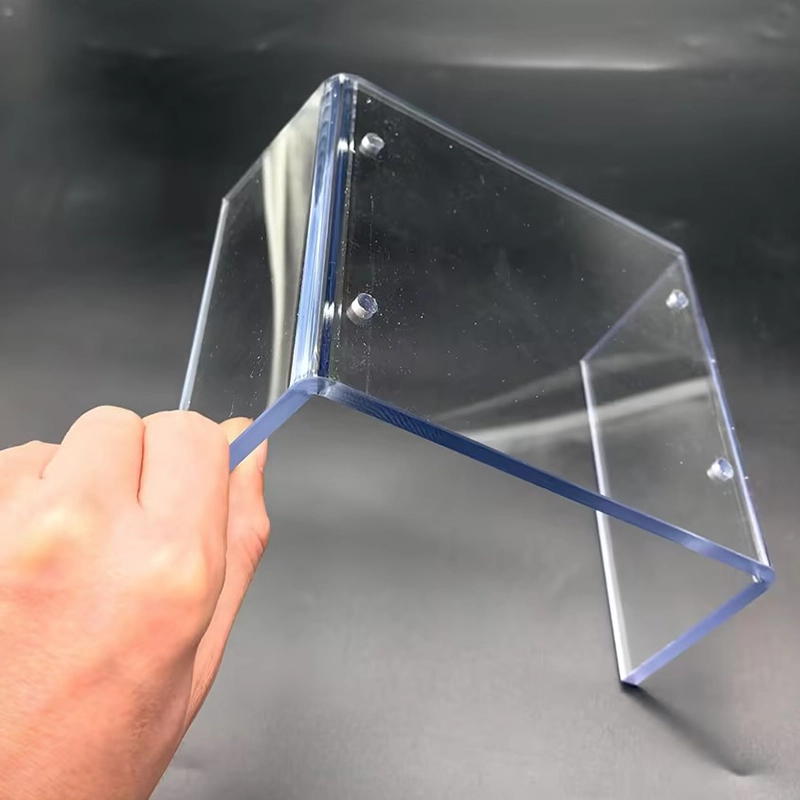

Polycarbonate / plexiglass tiv thaiv vaj tse npog nrog kab khoov rau cov khoom siv hluav taws xob

Cov qib premium-qib polycarbonate lossis plexiglass (acrylic) tiv thaiv vaj tse thiab npog yog tsim los muab kev tiv thaiv zoo rau ntau yam khoom siv, tshuab, thiab cov khoom siv. Crafted los ntawm cov ntaub ntawv muaj kev cuam tshuam, tawg-resistant, cov ntaub ntawv tsim kev cai no muaj kev tiv thaiv zoo tshaj plaws tiv thaiv plua plav, khib nyiab, ya raws, thiab kev cuam tshuam lub cev, ua kom muaj kev nyab xeeb ntawm koj cov khoom muaj nqis. Nrog lawv cov pob tshab tsim thiab ntau yam kev xaiv mounting, cov vaj tse tiv thaiv thiab npog yog ib qho kev daws teeb meem tseem ceeb rau kev tiv thaiv cov khoom siv tseem ceeb hauv kev lag luam, kev lag luam, thiab chaw nyob.

Khoom npe: tiv thaiv vaj tse npog

Tus Kev: 1mm-10mm, Customized

Loj: Kev cai

Siam: Muaj Machinery, Cov Khoom Siv Hluav Taws Xob

Warranty: 10 Thiab lub xyoos

Qhia Tshwm

Cov qib premium-qib polycarbonate lossis plexiglass (acrylic) tiv thaiv vaj tse thiab npog yog tsim los muab kev tiv thaiv zoo rau ntau yam khoom siv, tshuab, thiab cov khoom siv. Crafted los ntawm cov ntaub ntawv muaj kev cuam tshuam, tawg-resistant, cov ntaub ntawv tsim kev cai no muaj kev tiv thaiv zoo tshaj plaws tiv thaiv plua plav, khib nyiab, ya raws, thiab kev cuam tshuam lub cev, ua kom muaj kev nyab xeeb ntawm koj cov khoom muaj nqis. Nrog lawv cov pob tshab tsim thiab ntau yam kev xaiv mounting, cov vaj tse tiv thaiv thiab npog yog ib qho kev daws teeb meem tseem ceeb rau kev tiv thaiv cov khoom siv tseem ceeb hauv kev lag luam, kev lag luam, thiab chaw nyob.

Industrial Machinery: Siv cov acrylic tiv thaiv npog los tiv thaiv cov khoom rhiab, lub cev muaj zog, lossis tswj vaj huam sib luag hauv qhov chaw tsim khoom.

Cov Khoom Siv Hluav Taws Xob: Tiv thaiv cov khoom siv hluav taws xob me me, cov rooj sib tham hauv Circuit Court, lossis cov khoom siv kuaj los ntawm plua plav, khib nyiab, thiab lub cev puas tsuaj.

Automotive Cheebtsam: Kev ruaj ntseg thiab tiv thaiv qhov tseem ceeb hauv tsheb, xws li cov khoom siv cav lossis cov tshuab hluav taws xob, thaum thauj lossis khaws cia.

Cov polycarbonate thiab plexiglass tiv thaiv vaj tse thiab npog yog qhov tseem ceeb rau kev lag luam, kev lag luam, thiab cov koom haum nrhiav kev tiv thaiv lawv lub luag haujlwm tseem ceeb cov cuab yeej siv, tshuab, thiab cov khoom siv los ntawm kev puas tsuaj rau lub cev, ib puag ncig, thiab kev siv tsis raug cai, thaum tswj kev pom thiab kev siv tau.

khoom parameter

Yam ntxwv | Muxwm | Cov ntaub ntawv |

Kev cuam tshuam lub zog | J/m | 88-92 |

Lub teeb kis tau tus mob | % | 50 |

Specific Gravity | g / m | 1.2 |

Elongation thaum so | % | ≥130 |

Coefficient thermal expansion | mm/m ℃ | 0.065 |

Kev pabcuam kub | ℃ | -40℃~+120℃ |

Thaum tshav kub kub conductive | W/m² ℃ | 2.3-3.9 |

Flexural zog | N / mm² | 100 |

Modulus ntawm elasticity | Mpa | 2400 |

Tensile zog | N / mm² | ≥60 |

Soundproof Index | dB | 35 decibel txo rau 6 hli khoom ntawv |

Txhua yam andvantage koj yuav tsum paub txog peb

Daim ntawv thov khoom

Industrial Machinery: Tiv thaiv cov khoom rhiab, tswj, thiab cov khoom siv hauv cov chaw tsim khoom, tsev khaws khoom, thiab chaw tsim khoom.

Cov Khoom Siv Hluav Taws Xob: Tiv thaiv cov khoom siv hluav taws xob me me, cov khoom siv hluav taws xob, thiab cov cuab yeej siv hauv kev lag luam, thaj chaw, thiab chaw ua haujlwm.

Automation thiab Robotics: Kaw cov tshuab robotic, tswj vaj huam sib luag, thiab cov khoom siv automation los tiv thaiv kev puas tsuaj thiab ua kom cov neeg siv kev nyab xeeb.

Cov Khoom Siv Kho Mob: Muab cov ntaub thaiv tiv thaiv rau cov khoom siv kho mob, cov cuab yeej kuaj mob, thiab cov cuab yeej kuaj hauv cov chaw kho mob.

Cov Khoom Muag Khoom Muag: Txhim kho qhov kev nthuav qhia ntawm koj cov khoom lossis cov lus qhia thaum ua kom lawv ruaj ntseg nrog lub pob tshab acrylic npog.

Tsev Kho Kom Zoo Nkauj: Siv lub npog tiv thaiv kom nthuav tawm thiab khaws koj cov duab ntxim nyiam, cov khoom sau, lossis cov khoom zoo nkauj.

Cov Tsev Kawm Ntawv Kev Kawm: Tiv thaiv kev kawm qhia, qauv, lossis cov khoom siv hauv chav kuaj nrog lub npog acrylic ruaj khov.

Lwm cov txheej txheem

● Drilling: Qhov thiab qhov qhib tuaj yeem tsim hauv PC boards siv cov txheej txheem drilling.

● Khoov thiab sib sau: PC boards tuaj yeem khoov thiab tsim rau hauv cov duab uas xav tau siv cua sov.

● Thermoforming: Thermoforming yog txheej txheem uas cov ntawv PC uas muaj cua sov tau muab tso rau hauv pwm thiab tom qab ntawd lub tshuab nqus tsev lossis lub siab yog siv los tsim cov khoom kom haum cov pwm contours.

● CNC Milling: CNC milling tshuab nruab nrog cov cuab yeej txiav tsim nyog tuaj yeem siv los zeb PC boards

● Kev sib khi thiab kev sib koom ua ke: PC boards tuaj yeem txuas lossis koom ua ke siv ntau txoj hauv kev

● Surface Finishing: PC boards tuaj yeem ua tiav los txhim kho lawv cov tsos lossis muab cov haujlwm tshwj xeeb.

Vim li cas thiaj xaiv peb?

ABOUT MCLPANEL

Peb pab tau peb?

FAQ