Yambirani pa PC / PMMA PANGANO NDI NTCHITO jason@mclsheet.com +86-187 0196 0126

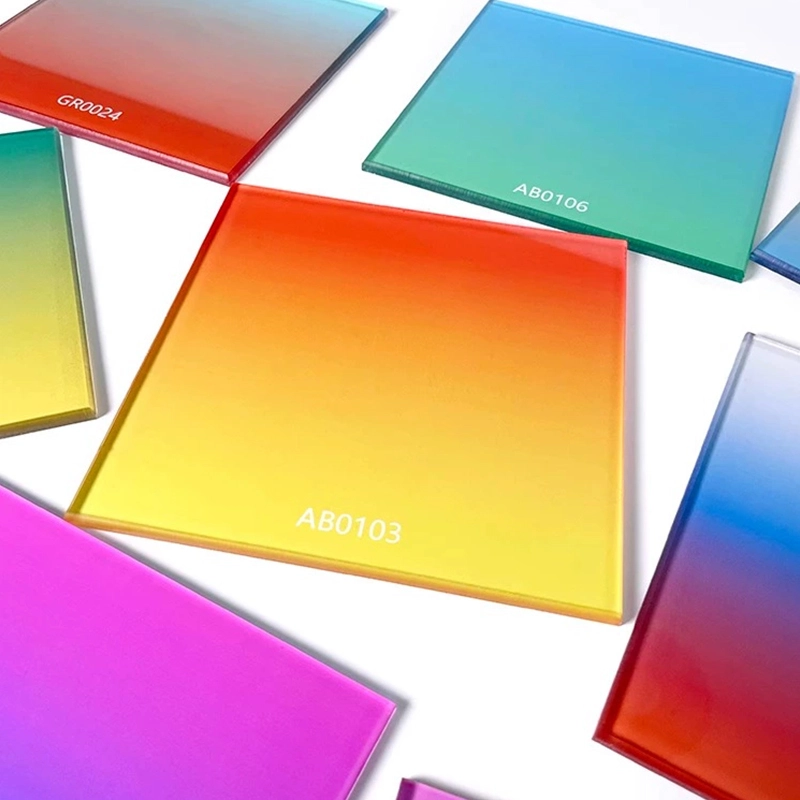

Mwambo lridescent Rainbow Mtundu Acrylic Sheet Zokongoletsa

Ma sheet a acrylic amtundu wa gradient ndi zinthu zosunthika komanso zowoneka bwino zomwe zimagwiritsidwa ntchito mosiyanasiyana, kuphatikiza kapangidwe ka mkati, zikwangwani, zaluso, ndi zokongoletsa. Mapepalawa amakhala ndi kusintha kwapang&39;onopang&39;ono pakati pa mitundu iwiri kapena kuposerapo, kupanga mawonekedwe owoneka bwino komanso amakono

Zakuthupi: 100% virgin material

Makulidwe: 10, 15, 20, 25, 30 mm

Mtundu: Mitundu itatu ya gradients

Satifiketi: CE, SGS, DE, ndi ISO 9001

MOQ: 2 matani, akhoza kusakanikirana ndi mitundu / Kukula / makulidwe

Kutumiza: 10-25 masiku

Product Description

Gradient color acrylic sheets are versatile and attractive materials often used in various applications, including interior design, signage, crafts, and decorative projects. These sheets feature a gradual transition between two or more colors, creating a visually appealing and modern look. Below is some information and examples of where gradient acrylic sheets are used:

Features of Gradient Color Acrylic Sheets

Smooth Color Transition: Gradient sheets offer a seamless color transition that adds depth and sophistication.

Durability: Acrylic is lightweight, impact-resistant, and weather-resistant, making it suitable for both indoor and outdoor use.

Customizable: Easily cut, shaped, or engraved to fit specific design needs.

Light Diffusion: Great for applications requiring light diffusion, such as lampshades or illuminated displays.

Transparency Options: Available in a range of opacities, from completely transparent to frosted or semi-transparent.

Aesthetic Appeal: The gradient effect adds a modern, stylish touch to any application.

product parameters

Material | 100% virgin material |

Thickness | 10,15,20, 30mm |

Color | Gradient color |

Standard size | 1220*1830, 1220*2440, 1270*2490, 1610*2550, 1440*2940, 1850*2450, 1050*2050, 1350*2000, 2050*3050, 1220*3050 mm |

Certificate | CE, SGS, DE, and ISO 9001 |

Equipment | Imported glass models (from Pilkington Glass in U. K.) |

MOQ | 2 tons, can be mixed with colors/ sizes/ thickness |

Delivery | 10-25 days |

Product application

1.Interior Design

• Wall panels or decorative cladding

• Room dividers and partitions

• Furniture accents (e.g., tabletops, shelves, or cabinet doors)

2. Lighting Design

• Lampshades with gradient effects

• Backlit panels for ambient lighting

• Diffusion panels for LED lighting

3. Signage and Branding

• Storefront signs and logos

• Illuminated signs with gradient acrylic for vibrant effects

• Directional or informational signage

4. Retail and Commercial Displays

• Product displays and stands

• Shelving with gradient color accents

• Visual merchandising to attract customers

5. Art and Decorative Projects

• Art installations or wall art

• DIY crafts and custom designs

• Photo or poster frames with gradient accents

CUSTOM SIZE

Acrylic is a versatile material that can be processed using a variety of common manufacturing techniques. Here are some of the most common acrylic fabrication and processing methods:

Cutting and Shaping:

Laser Cutting: Precise and clean cuts can be achieved using computer-controlled laser cutting machines.

CNC Machining: Computer Numerical Control (CNC) milling and routing machines can be used to cut complex shapes and profiles in Acrylic/polycarbonate.

Bonding and Joining:

Adhesive Bonding: Acrylic/polycarbonate can be joined using various adhesives, such as cyanoacrylate (super glue), epoxy, or acrylic-based cements.

Solvent Bonding: Solvents like methylene chloride or acrylic-based cements can be used to chemically weld acrylic parts together.

Bending and Forming:

Thermoforming: Acrylic/polycarbonate sheets can be heated and formed into various shapes using molds or bending jigs.

Cold Bending: Acrylic/polycarbonate can be bent and shaped at room temperature, particularly for simple curves and angles.

Flame Bending: Carefully applying a flame to the Acrylic/polycarbonate surface can soften the material, allowing it to be bent and shaped.

Printing and Decoration:

Screen Printing: Acrylic/polycarbonate sheets can be screen printed with various inks and graphics to add visual interest or branding.

Digital Printing: Wide-format digital printers can be used to directly print images, text, or graphics directly onto acrylic surfaces.

WHY CHOOSE US?

Inspire Creative Architecture with MCLpanel

MCLpanel is professional in polycarbonate production, cut, package and installation. Our team always helps you find the best solution.

ABOUT MCLPANEL

Our advantage

FAQ