Focus on PC/PMMA sheet production and processing jason@mclsheet.com +86-187 0196 0126

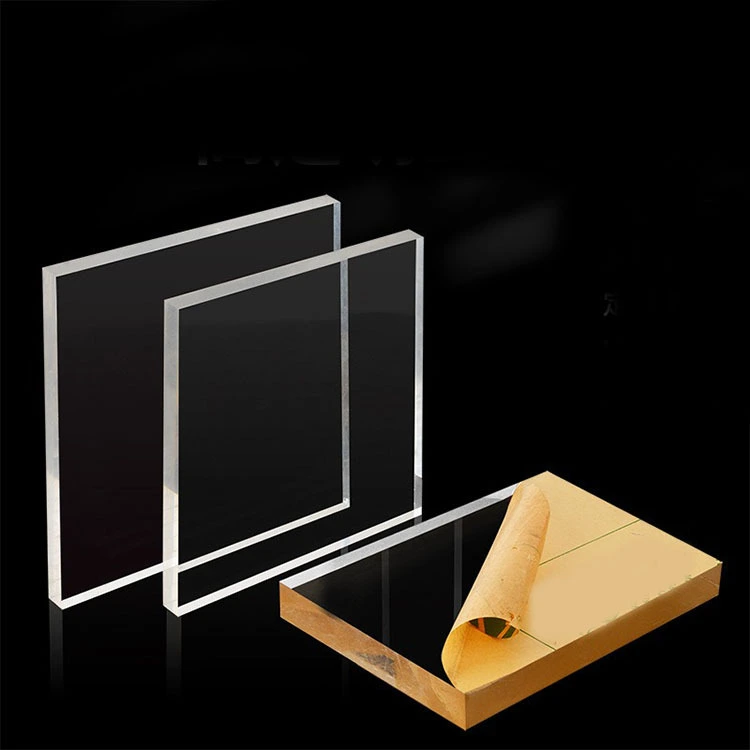

Custom 4x8 ft clear pmma acrylic plastic sheet 2mm 3mm 8mm from china suppliers

Clear acrylic sheets are a popular and versatile material known for their clarity and durability. these sheets are often used as a lightweight and shatter-resistant alternative to glass. Their optical clarity allows for excellent light transmission, making them ideal for applications where transparency is essential, such as display cases, windows, and protective barriers.

Material: 100% virgin material

Thickness: 1.8, 2, 3, 4, 5, 8, 10, 15, 20, 30mm (1.8-30mm)

Color: transparent, white, opal, black, red, green, blue, or OEM

Certificate: CE, SGS, DE, and ISO 9001

MOQ: 2 tons, can be mixed with colors/ Sizes/ thickness

Delivery: 10-25 days

Product Description

Clear acrylic plastic sheets, also known as plexiglass or polymethyl methacrylate (PMMA), are a popular choice for a wide range of applications due to their exceptional optical clarity, durability, and design flexibility. These transparent sheets offer numerous benefits that make them a valuable material in the construction, design, and manufacturing industries.

Key Characteristics of Clear Acrylic plastic sheets:

Optical Clarity:

Clear acrylic sheets provide exceptional clarity and transparency, allowing for unobstructed visibility and light transmission.

They exhibit a high refractive index, which results in a glass-like appearance and can enhance the aesthetic appeal of a space.

Lightweight and Impact-Resistant:

Acrylic sheets are significantly lighter than glass, typically about half the weight of an equivalent glass panel.

Despite their lightweight nature, they possess excellent impact resistance, making them a safer option in high-traffic areas or applications where safety is a concern.

Weather and UV Resistance:

Clear acrylic sheets are highly resistant to weathering, UV radiation, and other environmental factors, ensuring long-lasting performance and minimal discoloration over time.

This durability makes them suitable for both indoor and outdoor applications, including exposure to sunlight.

Versatility in Fabrication and Finishing:

Acrylic sheets can be easily cut, drilled, bent, and thermoformed, allowing for a wide range of customization and fabrication possibilities.

They can be polished, etched, or decorated with various techniques to achieve desired aesthetic effects.

Easy Maintenance and Cleaning:

Clear acrylic sheets require minimal maintenance compared to glass, as they are less prone to scratches and can be easily cleaned with mild detergents or specialized acrylic cleaners.

This low-maintenance feature makes them suitable for high-traffic areas and applications where cleanliness is important.

product parameters

|

Material |

100% virgin material |

|

Thickness |

1.8, 2, 3, 4, 5, 8,10,15,20, 30, 50,60mm (1.8-60mm) |

|

Color |

Transparent, white, opal, black, red, green, blue, yellow, etc. OEM color OK |

|

Standard size |

1220*1830, 1220*2440, 1270*2490, 1610*2550, 1440*2940, 1850*2450, 1050*2050, 1350*2000, 2050*3050, 1220*3050 mm |

|

Certificate |

CE, SGS, DE, and ISO 9001 |

|

Equipment |

Imported glass models (from Pilkington Glass in U. K.) |

|

MOQ |

2 tons, can be mixed with colors/ sizes/ thickness |

|

Delivery |

10-25 days |

Advantages

PRODUCT Advantages

Product application

● Windows and Glazing: Acrylic sheets are used for windows in commercial buildings, residential homes, and vehicles.

● Signage and Displays: Acrylic sheets are commonly used in signage applications, including indoor and outdoor signs, illuminated signs, point-of-sale displays, and trade show exhibits.

● Protective Barriers and Shields: Acrylic sheets are used to create protective barriers and shields in various settings.

● Lighting Fixtures: Acrylic sheets are utilized in lighting applications, such as diffusers and light covers, to distribute and diffuse light evenly.

● Aquariums and Display Cases: Acrylic sheets are often used in the construction of aquariums, fish tanks, and display cases.

● Furniture and Home Decor: Acrylic sheets are used to create furniture pieces, such as chairs, tables, and shelves.

● Medical and Healthcare Equipment: Acrylic sheets are employed in the healthcare industry for applications such as isolation chambers, medical equipment components, protective barriers in laboratories, and medical device enclosures.

● Roofing and Skylights: Acrylic sheets are used as roofing materials and in skylights to allow natural light into buildings.

● Art and Craft Projects: Acrylic sheets are popular among artists and crafters for various projects.

● Greenhouses: Acrylic sheets are used in greenhouse construction to create a controlled environment for plant growth.

color

Acrylic sheets are available in a wide variety of colors, allowing for flexible design options. Here's an overview of the main acrylic color choices:

Clear/Transparent:

This is the most common and popular acrylic color option. Clear acrylic offers excellent optical clarity.

Tinted/Colored:

Acrylic can be pigmented during manufacturing to create a wide range of solid colors, including:

Red

Blue

Green

Yellow

Black

White

And many other hues

Translucent:

Translucent acrylic sheets allow some light to pass through while providing a diffused, frosted appearance.

These can create interesting lighting effects and decorative looks.

COMMON PROCESSING

Acrylic/polycarbonate is a versatile material that can be processed using a variety of common manufacturing techniques. Here are some of the most common acrylic fabrication and processing methods:

Cutting and Shaping:

Laser Cutting: Precise and clean cuts can be achieved using computer-controlled laser cutting machines.

CNC Machining: Computer Numerical Control (CNC) milling and routing machines can be used to cut complex shapes and profiles in Acrylic/polycarbonate.

Bonding and Joining:

Adhesive Bonding: Acrylic/polycarbonate can be joined using various adhesives, such as cyanoacrylate (super glue), epoxy, or acrylic-based cements.

Solvent Bonding: Solvents like methylene chloride or acrylic-based cements can be used to chemically weld acrylic parts together.

Bending and Forming:

Thermoforming: Acrylic/polycarbonate sheets can be heated and formed into various shapes using molds or bending jigs.

Cold Bending: Acrylic/polycarbonate can be bent and shaped at room temperature, particularly for simple curves and angles.

Flame Bending: Carefully applying a flame to the Acrylic/polycarbonate surface can soften the material, allowing it to be bent and shaped.

Printing and Decoration:

Screen Printing: Acrylic/polycarbonate sheets can be screen printed with various inks and graphics to add visual interest or branding.

Digital Printing: Wide-format digital printers can be used to directly print images, text, or graphics directly onto acrylic surfaces.

WHY CHOOSE US?

ABOUT MCLPANEL

Our advantage

FAQ