Focus on PC/PMMA sheet production and processing jason@mclsheet.com +86-187 0196 0126

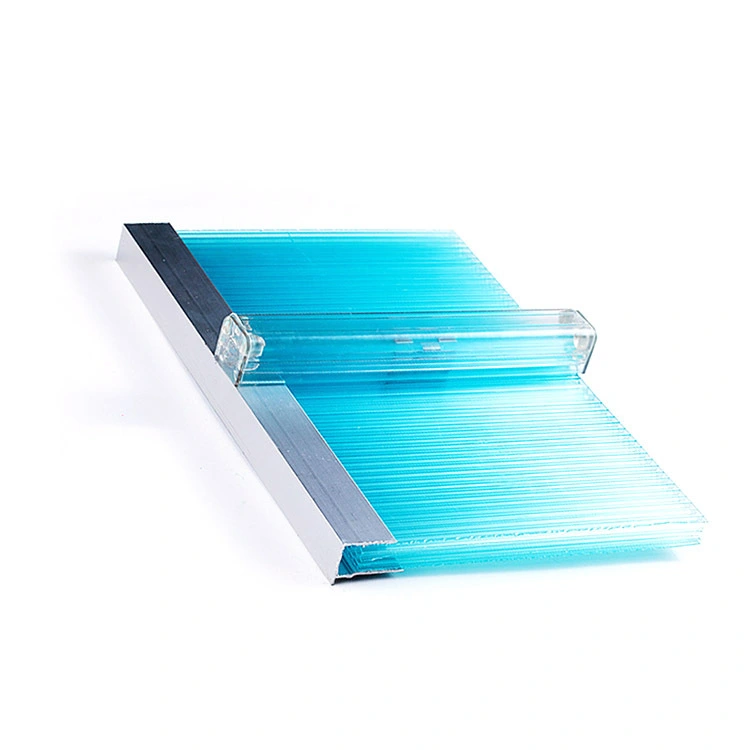

Custom translucent X-wall inter lock polycarbonate rooflights sheets for architecture

X-wall Inter lock polycarbonate rooflights sheets have gained significant popularity in the construction industry due to their unique design features and wide range of applications. These innovative building products combine the advantages of polycarbonate material with an interlocking system, offering versatile and modular solutions for various construction and architectural needs.

Product name: X-wall inter lock polycarbonate rooflights sheets

Width: 600mm and 1040mm

Thickness: 8mm-40mm

Color: Clear, Opal, Blue, Lake Blue, Green, Bronze, or Customized

Length: Customized

Structure: X-wall u-lock, Multi-wall u-lock, Honycomb u-lock

U lock polycarbonate sheets Description

X-wall inter lock polycarbonate rooflights sheets is an advanced roofing system. It adopts a U-shaped lock structure that is easy to install, and the sheet is fixed without nails. Fully considering the thermal expansion coefficient of polycarbonate, the panel can slide at the fixed corner. Free sliding expansion and contraction in the groove, the panel can be freely deformed to eliminate internal stress.

The fixed angle code fixes the X-wall inter lock polycarbonate rooflights sheets on the roof purlin, and the connecting buckle and the connecting teeth of the panel are engaged with each other to achieve a fast and reliable connection. closed system.U-locked polycarbonate sheet system is superior glazing roof material with multi-wall, honeycomb, or X-structure for optional.

It combines high thermal insulation, lightweight and high impact. Compared with general polycarbonate, it has a superior leak-proof structure, fantastic loads and simple installation. And the polycarbonate joiner offers free expansion and contraction space. These features make it ideal for building cladding, industrial glazing roof and architectural curved roofing designs.

product parameters

|

Products Name |

X-wall inter lock polycarbonate rooflights sheets |

|

Type |

X-wall u-lock, Multi-wall u-lock, Honeycomb u-lock |

|

Size |

Width 600mm or 1040mm , Length costom |

|

Thickness |

8mm, 10mm, 16mm 20mm 25mm or customized |

|

UV-protected |

50um on one side or both sides |

|

Temperature range |

-40℃~+120℃ |

|

Light transmission |

72%-65% |

|

MOQ |

100 sqm |

What is a U-locked Polycarbonate Sheet System?

X-wall inter lock polycarbonate rooflights sheets have gained significant popularity in the construction industry due to their unique design features and wide range of applications. These innovative building products combine the advantages of polycarbonate material with an interlocking system, offering versatile and modular solutions for various construction and architectural needs.

Interlocking Design:

Interlocking polycarbonate rooflights sheets feature a specialized edge profile that allows them to interlock seamlessly with one another.

This interlocking mechanism creates a secure and weathertight connection, simplifying the installation process and enhancing the overall structural integrity of the assembly.

Modularity and Flexibility:

The interlocking design of these sheets enables easy installation and modification, allowing for rapid and adaptable construction.

Panels can be quickly assembled, disassembled, and rearranged as needed, making them suitable for both permanent and temporary structures.

Polycarbonate Interlocking panel system offers a variety of colors like clear, opal, bronze,lake-blue and glass-green. UV protection is on the surface that blocks all rays to help control the temperature and anti-yellowing. It is excellent durable, lasting 15-20 years.

U lock polycarbonate sheets installtion

- As the new structure, U-locked polycarbonate system is connected by aluminum or polycarbonate joiner that Accommodates expansion and contraction and sealed by end-caps that prevents dirty and drainage. No need for any point fastener penetration through the sheets. It is very easy to install. The installation guide is shown below

U LOCK sheet application

● Building glazing roof

● Commercial and retail building roof

● Stadiums roofs and swimming pool enclosure

● Architectural dome daylight

● Venues roofing

● Factory lighting skylight, canopy, facade lighting, partition

● Covered walkways, awnings & entrances

● Conservatories and agricultural greenhouse

U LOCK SHEET Features

● Material: The sheets are made of high-quality polycarbonate, which is a strong and lightweight thermoplastic material.

● UV Protection: The sheets are UV-protected with a high-density layer, ensuring long-lasting performance and preventing yellowing or degradation caused by sunlight exposure.

● Impact Resistance: U lock PC hollow sheets have enhanced impact strength, making them resistant to winds, rains, hailstorms, and other weather conditions.

● Light Transmittance: These sheets offer higher light transmittance rates, allowing natural light to enter while maintaining a comfortable indoor environment.

● Easy Installation: U lock polycarbonate Interlocking panels are easy to install and can be smoothly drilled during construction.

● Versatility: These sheets are available in various colors, styles, designs, shapes, and material features to suit different requirements.

U LOCK SHEET Structure

| Muilt-wall U-lock sheet | X-wall U-lock sheet | Honycomb U-lock sheet | solid U-lock sheet |

|  |  |  |

Superior Material for Building Cladding , U-locked Polycarbonate Panel System

U-lock polycarbonate sheet series is a new generation of innovative goods. it fundamentally settles the issue of thermal expansion and shrinkage of general panels, the unique design 100% solved the water seepage problem caused by the wrong operation of the installation surface, also the installation is faster and stronger, and the maintenance is more convenient. The variety of sheets structure and color satisfies customers’ choice of different transmittance and thermal insulation functions. U-locked polycarbonate system is prior material for building cladding.

Advantages of PC U-Lock sheet than FRP sheet

1.Better deformation performance: PC U-lock sheet roofing system, U-shaped buckle and plate are all made of polycarbonate, which ensures that they have the same deformation performance, when the temperature changes, the plate and the U-shaped buckle move in the same direction , to eliminate the hidden danger of water leakage. FRP needs to be fixed with screws. The deformation of screws and FRP is different materials, and there will be a hidden danger of water leakage.

2.Better light transmittance: Although the transmittance of PC and FRP is very high, which can reach about 85%, the PC board has high transmittance and will not produce haze. FRP is a composite of glass fiber, resin and other materials, which has poor permeability and is prone to haze.

3.Better thermal insulation performance: The heat transfer coefficient of PC is 0.2W/M.k. The heat transfer coefficient of FRP is 0.4. Therefore, the thermal insulation performance of PC is twice that of FRP, and the PC board is a hollow structure with good thermal insulation performance.

- Better flame retardancy: PC material can achieve high flame retardancy without adding any flame retardant, and it is self-priming from fire. The fire rating of our panels is UL94-V2. FRP contains resin, which is flammable and needs to add flame retardant, and the cost will be higher than that of PC board, which is not economical

- Better weather resistance: The normal working temperature of PC is minus 40 degrees to plus 120 degrees, while FRP is minus 20 degrees to 45 degrees. Beyond this range, the performance of FRP is greatly reduced

- Easier construction: PC board is a hollow structure, with light specific gravity, easier construction, U-shaped locking system, more convenient and fast construction, saving construction period.

Better environment friendly material: PC U-lock sheet are made of polycarbonate which is environmentally friendly and safe to body.

Why choose us?

ABOUT MCLPANEL

Our advantage

FAQ