Focus on PC/PMMA sheet production and processing jason@mclsheet.com +86-187 0196 0126

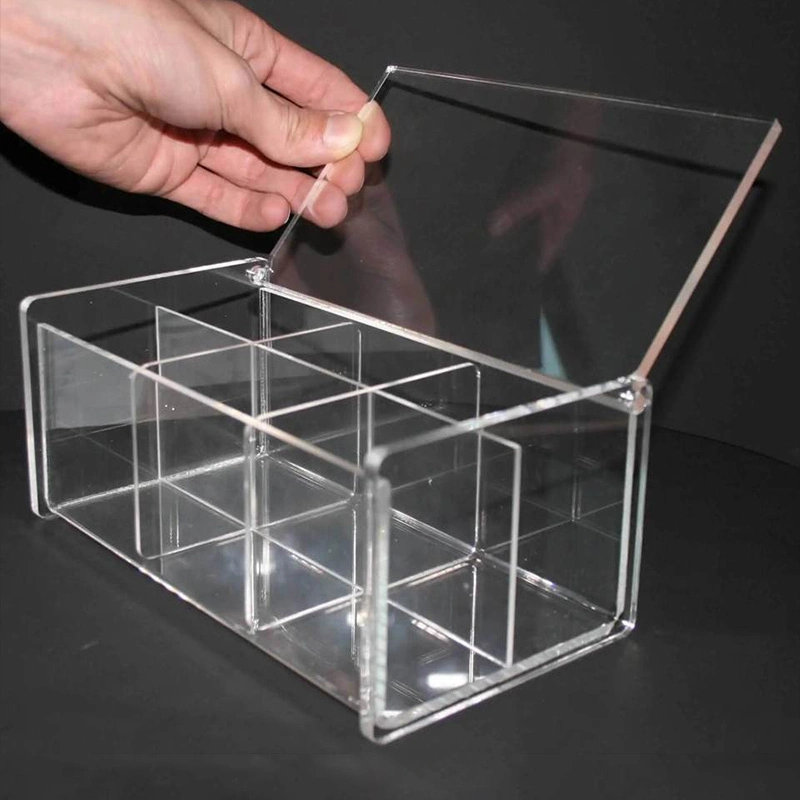

Square acrylic/polycarbonate storage box by bonding processing for sign display stand

Acrylic/Polycarbonate bonding boxes are a specialized type of enclosure or housing made from clear acrylic sheets that are precisely cut and bonded together using a variety of adhesives. These boxes are designed to provide a durable, transparent, and customizable solution for a wide range of applications, from product display and packaging to prototyping and scientific equipment.

Product Name: pc/pmma bonding

Thickness: 1mm-20mm, customized

Width: 1000/1220/2000mm, custom

Length: 2000/2440mm, custom

Warranty: 10 years

Product Description

Acrylic/Polycarbonate bonding boxes are a specialized type of enclosure or housing made from clear acrylic sheets that are precisely cut and bonded together using a variety of adhesives. These boxes are designed to provide a durable, transparent, and customizable solution for a wide range of applications, from product display and packaging to prototyping and scientific equipment.

Key Features and Applications of Bonding Boxes:

Transparency: The inherent clarity of acrylic allows for unobstructed visibility of the contents within the box, making it an ideal choice for display and showcasing applications.

Customizability: Acrylic/Polycarbonate can be easily cut, shaped, and engraved, enabling the creation of custom-designed boxes to meet specific size, shape, and style requirements.

Product Display: Acrylic/Polycarbonate bonding boxes are commonly used to create attractive and secure display cases for showcasing various products, such as jewelry, collectibles, electronics, and other valuable items.

Packaging and Protection: These boxes provide a durable and protective enclosure for delicate or valuable items, making them suitable for packaging and transportation applications.

product parameters

|

Characterics |

Unit |

Data |

|

Impact strength |

J/m |

88-92 |

|

Light transmission |

% |

50 |

|

Specify Gravity |

g/m |

1.2 |

|

Elongation at break |

% |

≥130 |

|

Coefficient thermal expansion |

mm/m℃ |

0.065 |

|

Service temperature |

℃ |

-40℃~+120℃ |

|

Heat conductively |

W/m²℃ |

2.3-3.9 |

|

Flexural strength |

N/mm² |

100 |

|

Modulus of elasticity |

Mpa |

2400 |

|

Tensile strength |

N/mm² |

≥60 |

|

Soundproof index |

dB |

35 decibel decrease for 6mm solid sheet |

PRODUCT advantage

Choose us, and we promise to do everything needed to ensure a successful and satisfactory working partnership. Key Features of Acrylic Bonding Boxes

Product application

Product Display and Showcasing:

- Acrylic/polycarbonate's transparency allows for unobstructed visibility, making these boxes ideal for displaying and showcasing a variety of products, such as:

- Jewelry and accessories

- Collectibles and memorabilia

- Electronics and gadgets

- Art and decorative items

- The customizable nature of acrylic boxes enables the creation of visually appealing and attention-grabbing displays.

- Acrylic/polycarbonate's transparency allows for unobstructed visibility, making these boxes ideal for displaying and showcasing a variety of products, such as:

Packaging and Protection:

- Acrylic/polycarbonate bonding boxes provide a durable and protective enclosure for delicate or valuable items, ensuring safe transportation and storage.

- These boxes are commonly used for packaging:

- Fragile electronics and devices

- Luxury and high-end products

- Sensitive medical or scientific equipment

- The lightweight and scratch-resistant properties of acrylic make it a suitable material for packaging applications.

Prototyping and Modeling:

- Acrylic/polycarbonate's ease of fabrication and modification makes it a popular choice for creating functional prototypes and scale models in various industries.

- Acrylic/polycarbonate bonding boxes are used for:

- Product design and development

- Architectural and engineering modeling

- Educational and scientific demonstrations

Scientific and Educational Applications:

- Acrylic/polycarbonate bonding boxes are utilized in educational settings for science experiments, demonstrations, and hands-on activities.

- In the scientific and research fields, these boxes are employed as:

- Enclosures for specialized equipment

- Containment systems for experiments and tests

- Observation chambers for biological or chemical processes

Furniture and Decor:

- Acrylic/polycarbonate is increasingly being used in furniture and home decor applications, with acrylic bonding boxes serving as:

- Table tops and shelves

- Storage units and display cases

- Decorative elements like vases and light fixtures

- Acrylic/polycarbonate is increasingly being used in furniture and home decor applications, with acrylic bonding boxes serving as:

common processing

Acrylic/polycarbonate is a versatile material that can be processed using a variety of common manufacturing techniques. Here are some of the most common acrylic fabrication and processing methods:

Cutting and Shaping:

- Laser Cutting: Precise and clean cuts can be achieved using computer-controlled laser cutting machines.

- CNC Machining: Computer Numerical Control (CNC) milling and routing machines can be used to cut complex shapes and profiles in Acrylic/polycarbonate.

Bonding and Joining:

- Adhesive Bonding: Acrylic/polycarbonate can be joined using various adhesives, such as cyanoacrylate (super glue), epoxy, or acrylic-based cements.

- Solvent Bonding: Solvents like methylene chloride or acrylic-based cements can be used to chemically weld acrylic parts together.

Bending and Forming:

- Thermoforming: Acrylic/polycarbonate sheets can be heated and formed into various shapes using molds or bending jigs.

- Cold Bending: Acrylic/polycarbonate can be bent and shaped at room temperature, particularly for simple curves and angles.

- Flame Bending: Carefully applying a flame to the Acrylic/polycarbonate surface can soften the material, allowing it to be bent and shaped.

Printing and Decoration:

- Screen Printing: Acrylic/polycarbonate sheets can be screen printed with various inks and graphics to add visual interest or branding.

- Digital Printing: Wide-format digital printers can be used to directly print images, text, or graphics directly onto acrylic surfaces.

Why choose us?

ABOUT MCLPANEL

Our advantage

FAQ