Focus on PC/PMMA sheet production and processing jason@mclsheet.com +86-187 0196 0126

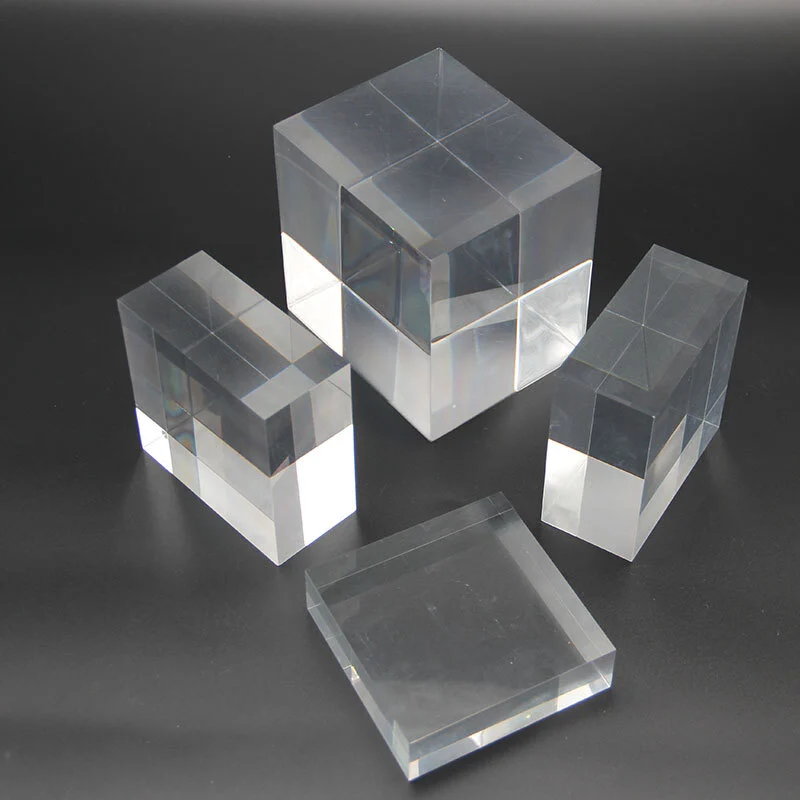

Wholesale thickened clear acrylic sheet 50mm 60mm 100mm with polished edge

Thickened clear acrylic sheets refer to acrylic panels that are significantly thicker than standard options, Commonly available in thicknesses of 1/2" (12mm), 3/4" (19mm), 1" (25mm), and even up to 2" (50mm) or more.

Name: Thickened clear acrylic sheet

Thickness: 30mm 50mm 80mm 100mm

Certificate: CE, SGS, DE, and ISO 9001

MOQ: 2 tons, can be mixed with colors/ Sizes/ thickness

Delivery: 10-25 days

Product Description

Thickened clear acrylic sheets refer to acrylic panels that are significantly thicker than standard options, Commonly available in thicknesses of 1/2" (12mm), 3/4" (19mm), 1" (25mm), and even up to 2" (50mm) or more.

The increased thickness provides enhanced rigidity and impact resistance compared to thinner acrylic.

Fabrication:

Thickened acrylic can be more challenging to fabricate, as it requires specialized saws, routers, and polishing techniques.

Edge finishing is important to maintain the clear, high-quality appearance.

Clarity and Optical Quality:

High-quality thickened acrylic maintains excellent optical clarity and light transmission, often over 90%.

Minor distortion or minor bubbles may be more visible in thicker panels compared to standard 1/4" or 1/8" acrylic.

Cost Considerations:

Thicker acrylic sheets are generally more expensive per square foot than standard thicknesses.

The cost increases as the thickness goes up, due to the raw material and specialized fabrication required.

Thickened clear acrylic sheets offer unique benefits for applications where increased rigidity, impact resistance, and structural integrity are important. Careful material selection and fabrication is key to achieving the desired optical quality.

product parameters

|

Material |

100% virgin material |

|

Thickness |

20, 30, 40, 50, 80,100,200, (10-200mm) |

|

Color |

Transparent, white, opal, black, red, green, blue, yellow, etc. OEM color OK |

|

Standard size |

1220*1830, 1220*2440, 1270*2490, 1610*2550, 1440*2940, 1850*2450, 1050*2050, 1350*2000, 2050*3050, 1220*3050 mm |

|

Certificate |

CE, SGS, DE, and ISO 9001 |

|

Equipment |

Imported glass models (from Pilkington Glass in U. K.) |

|

MOQ |

2 tons, can be mixed with colors/ sizes/ thickness |

|

Delivery |

10-25 days |

Advantages

PRODUCT Advantages

Product application

Thicker acrylic is often used for applications that require greater structural integrity, such as:

Table tops and countertops

Shelving and display cases

Machine guards and windshields

Aquarium and fish tank panels

color

Acrylic sheets are available in a wide variety of colors, allowing for flexible design options. Here's an overview of the main acrylic color choices:

Clear/Transparent:

This is the most common and popular acrylic color option. Clear acrylic offers excellent optical clarity.

Tinted/Colored:

Acrylic can be pigmented during manufacturing to create a wide range of solid colors, including:

Red

Blue

Green

Yellow

Black

White

And many other hues

Translucent:

Translucent acrylic sheets allow some light to pass through while providing a diffused, frosted appearance.

These can create interesting lighting effects and decorative looks.

COMMON PROCESSING

Acrylic/polycarbonate is a versatile material that can be processed using a variety of common manufacturing techniques. Here are some of the most common acrylic fabrication and processing methods:

Cutting and Shaping:

Laser Cutting: Precise and clean cuts can be achieved using computer-controlled laser cutting machines.

CNC Machining: Computer Numerical Control (CNC) milling and routing machines can be used to cut complex shapes and profiles in Acrylic/polycarbonate.

Bonding and Joining:

Adhesive Bonding: Acrylic/polycarbonate can be joined using various adhesives, such as cyanoacrylate (super glue), epoxy, or acrylic-based cements.

Solvent Bonding: Solvents like methylene chloride or acrylic-based cements can be used to chemically weld acrylic parts together.

Bending and Forming:

Thermoforming: Acrylic/polycarbonate sheets can be heated and formed into various shapes using molds or bending jigs.

Cold Bending: Acrylic/polycarbonate can be bent and shaped at room temperature, particularly for simple curves and angles.

Flame Bending: Carefully applying a flame to the Acrylic/polycarbonate surface can soften the material, allowing it to be bent and shaped.

Printing and Decoration:

Screen Printing: Acrylic/polycarbonate sheets can be screen printed with various inks and graphics to add visual interest or branding.

Digital Printing: Wide-format digital printers can be used to directly print images, text, or graphics directly onto acrylic surfaces.

WHY CHOOSE US?

ABOUT MCLPANEL

Our advantage

FAQ