Focus on PC/PMMA sheet production and processing jason@mclsheet.com +86-187 0196 0126

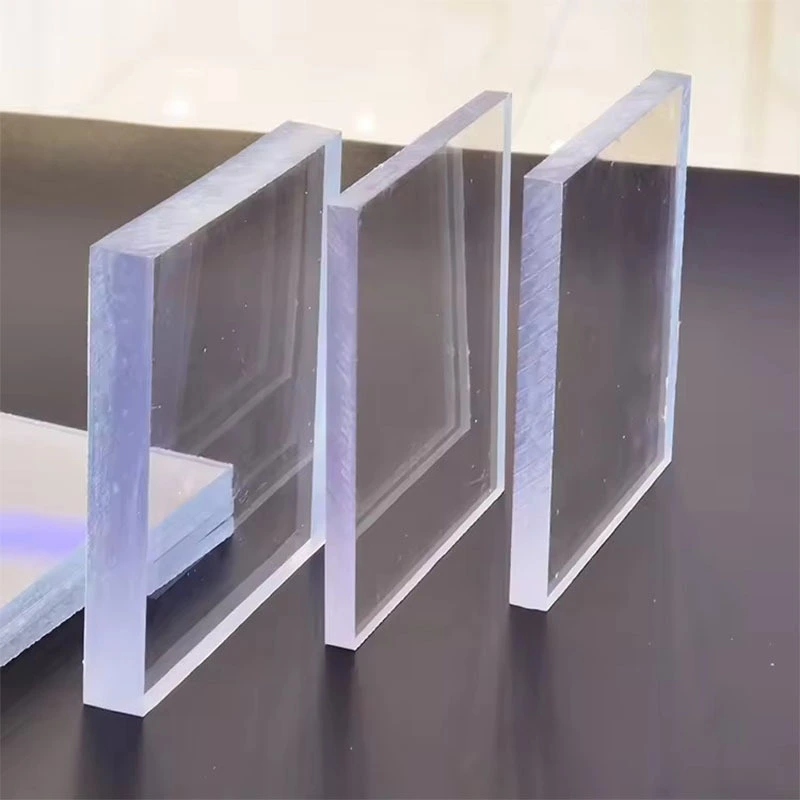

Industrial grade clear polycarbonate thick panel 15mm 20mm for bulletproof glass

Polycarbonate thick panels are durable, high-performance sheets made from polycarbonate resin. Known for their exceptional strength and impact resistance, these panels are often used in applications where safety, clarity, and thermal insulation are essential.

Product name: thick gauge polycarbonate sheets

size: 1050mm*2050mm、1220mm*2440mm or Customized

Thickness: 10mm 15mm 20mm 30mm 50mm

Color: Clear or Customized

Product Description

Polycarbonate extra thick sheets refer to a specialized variant of the polycarbonate material that features increased thickness compared to standard polycarbonate sheets. These thicker sheets offer enhanced durability, dimensional stability, and load-bearing capacity, making them suitable for applications that require enhanced structural integrity and protection.

Superior Impact Resistance: At 30mm thickness, these polycarbonate sheets can withstand severe impacts and are up to 250 times more impact-resistant than glass, making them ideal for safety-critical applications.

Optical Clarity: The transparent nature of the polycarbonate material allows for exceptional light transmission and visual clarity, enabling unobstructed visibility.

Dimensional Stability: The 20mm thickness ensures that the sheets maintain their shape and dimensions even under extreme environmental conditions, providing long-lasting performance.

Excellent Weatherability: Polycarbonate is highly resistant to the effects of UV radiation, temperature fluctuations, and environmental weathering, making it suitable for both indoor and outdoor use.

Lightweight Design: Despite their impressive thickness, 20mm polycarbonate sheets are significantly lighter in weight compared to alternative materials like acrylic or glass, simplifying installation and handling.

Versatile Fabrication: These thick polycarbonate sheets can be easily cut, drilled, and formed using standard woodworking and metalworking tools, allowing for customization and on-site modifications.

Polycarbonate extra thick sheets offer a unique combination of enhanced durability, dimensional stability, and structural integrity, making them a valuable solution for applications that require increased protection, load-bearing capacity, and resistance to physical impacts or environmental factors. By leveraging the inherent properties of polycarbonate and increasing the sheet thickness, these specialized products provide a practical and effective alternative to traditional glass, metal, or thinner polycarbonate materials in a wide range of industries and applications.

product parameters

|

Name |

Polycarbonate extra thick sheets |

|

Thickness |

10mm 15mm 20mm 30mm 50mm |

|

Color |

Transparent, white, opal, black, red, green, blue, yellow, etc. OEM color OK |

|

Standard size |

1220*1830, 1220*2440, 1440*2940, 1050*2050, 2050*3050, 1220*3050 mm |

|

Certificate |

CE, SGS, DE, and ISO 9001 |

|

MOQ |

2 tons, can be mixed with colors/sizes/thickness |

|

Delivery |

10-25 days |

extra thick sheets advantage

Polycarbonate sheets that are considered "extra thick" typically refer to those with a thickness of 15mm or greater. Here are some key details about polycarbonate extra thick sheets:

Product application

Building and Construction:

Structural glazing and curtain wall systems

Roof and skylight panels for enhanced load-bearing capacity

Protective barriers, partitions, and enclosures

Transportation and Automotive:

Windshields, side windows, and sunroofs for heavy-duty vehicles

Protective covers and guards for transportation equipment

Structural components in vehicles, trains, and aircraft

Industrial and Commercial Settings:

Protective covers and guards for machinery and equipment

Enclosures, housings, and panels for industrial applications

Shelving, partitions, and furniture in commercial environments

Aquarium and Terrarium Covers:

The optical clarity and dimensional stability of 30mm polycarbonate sheets make them a popular choice for constructing custom aquarium and terrarium covers.

CUSTOM TO SIZE

polycarbonate is a very popular material for oxygen chamber windows.

Polycarbonate is transparent, impact-resistant, and non-combustible, making it well-suited for the high-pressure, oxygen-rich environment.

Polycarbonate windows can be fabricated in various thicknesses and shape depending on the chamber size and pressure requirements.

1. Cutting:

- Cutting to Size: Polycarbonate sheets can be cut to the desired size using various methods, such as:

- Circular saws or table saws with fine-toothed blades designed for plastics

- CNC (Computer Numerical Control) routers or laser cutters for precise, custom shapes

- Manual scoring and snapping for simple straight-line cuts

- Cutting to Size: Polycarbonate sheets can be cut to the desired size using various methods, such as:

2. Trimming and Edging:

- Edge Finishing: The edges of the cut polycarbonate sheets can be finished using techniques like:

- Grinding or sanding to smooth the edges

- Applying edge treatments, such as decorative edge moldings or polished edges

- Edge Finishing: The edges of the cut polycarbonate sheets can be finished using techniques like:

3. Drilling and Punching:

- Holes and Openings: Polycarbonate sheets can be drilled or punched to create holes, slots, or other openings as required for the application.

- Specialized drill bits and punches designed for plastics are typically used to prevent cracking or chipping.

4. Thermoforming:

- Complex Shapes: Polycarbonate sheets can be thermoformed into various three-dimensional shapes, such as curved or contoured panels, using specialized molds and heating equipment.

- This process allows for the creation of custom-shaped parts from flat sheets.

Why choose us?

ABOUT MCLPANEL

Our advantage

FAQ