Focus on PC/PMMA sheet production and processing jason@mclsheet.com +86-187 0196 0126

Top Sellingsolid Polycarbonate Sheet for Military Camp

Product details of the solid polycarbonate sheet

Product Overview

Shanghai mclpanel New Materials Co., Ltd. employs solid polycarbonate sheet material, which is up to the national standard. This product has a long service life while delivering constantly high quality. Mclpanel's solid polycarbonate sheet is widely used in the industry. In order to meet the higher quality requirements of customers, Mclpanel has carried out refined quality assurance procedure.

Product Information

Compared with peer products, Mclpanel's solid polycarbonate sheet has the outstanding advantages, mainly reflected in the following aspects.

Product Description

Plug-Pattern Design: The plug-pattern design of these sheets consists of small plugs or protrusions on the surface, which helps to enhance the structural integrity and stability of the sheet.

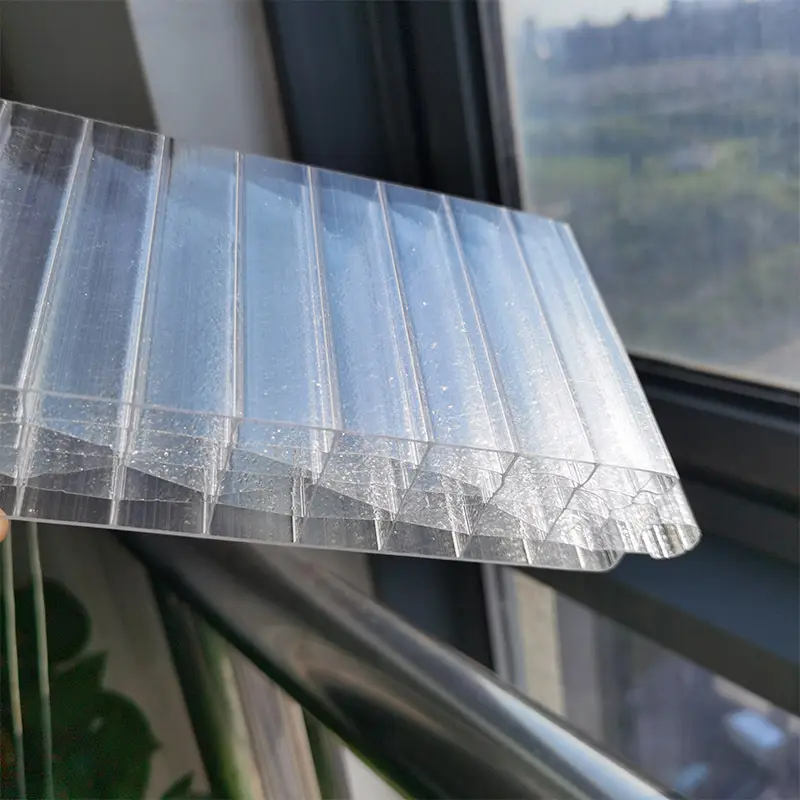

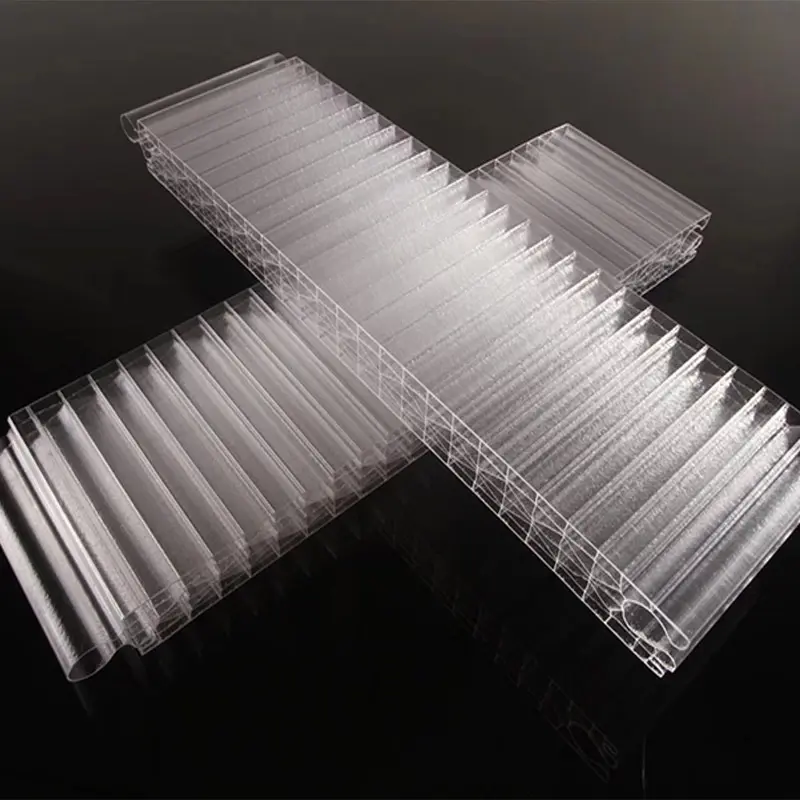

Seven-Wall Structure: The seven-wall X structure of these sheets provides increased strength and rigidity compared to standard multi-wall polycarbonate sheets. This makes them more resistant to impacts and bending .

Seamless Glazing Option: Some 7 Walls Plug-Pattern Sheets are produced with a thermoclick system on the side edges, allowing for a seamless glazing option. This makes the installation process easier and provides a visually appealing finish.

Polycarbonate facade panels have emerged as a popular choice for building exteriors and facades due to their exceptional performance and design versatility. These panels offer a range of benefits that make them an attractive option for architects, contractors, and building owners.

product parameters

|

Item |

Thickness |

Width |

Length |

|

Polycarbonate Plug-Pattern Panel |

30/40 mm |

500 mm |

5800 mm 11800 mm Customized |

|

Raw Material |

100% virgin Bayer/ Sabic |

||

|

Density |

1.2 g/cm³ |

||

|

Profiles |

7-Wall Rectangle/ Diamond Structure |

||

|

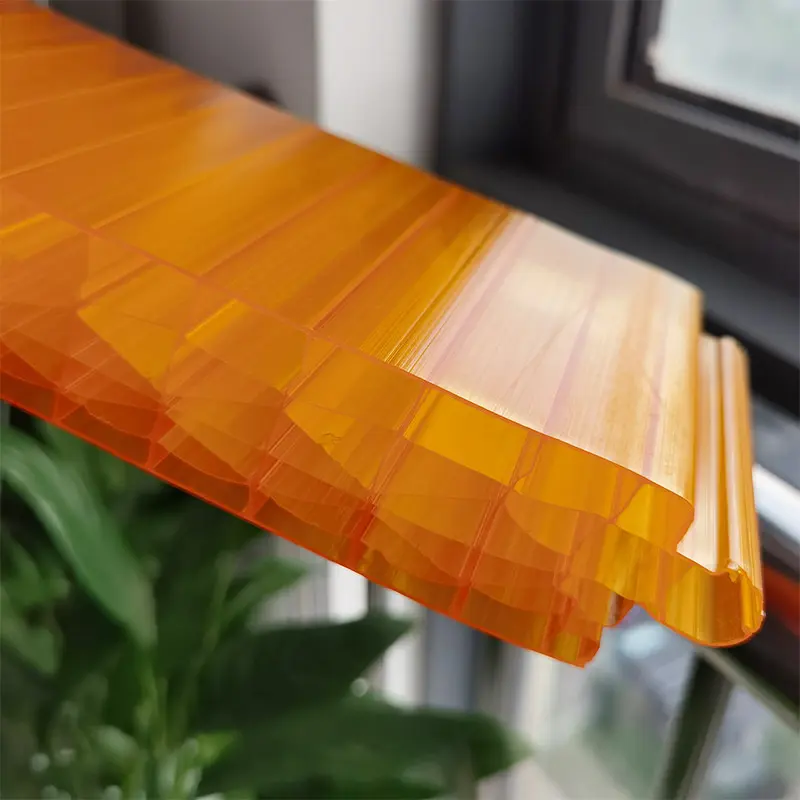

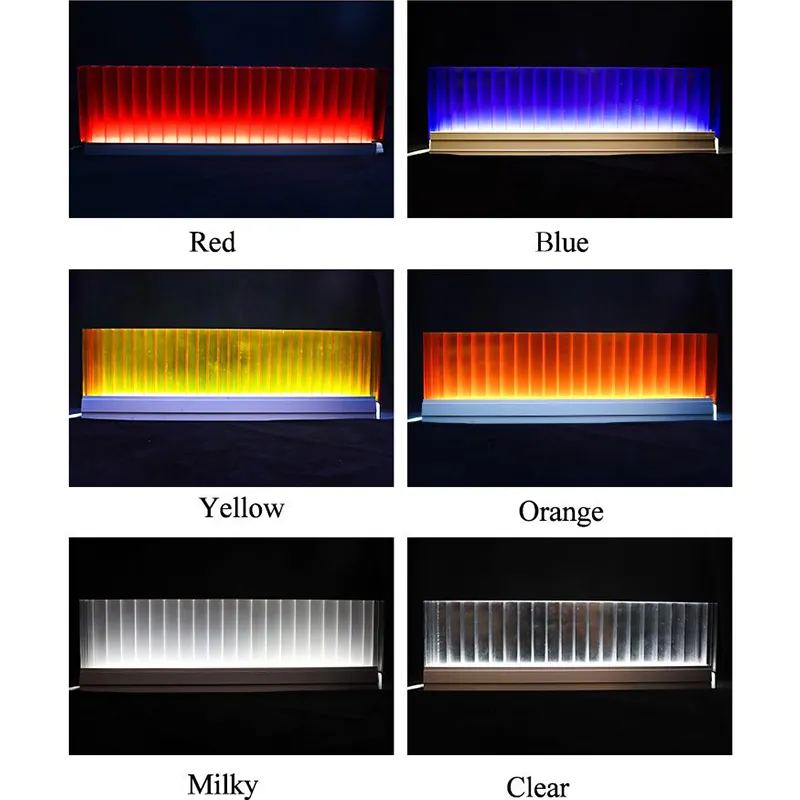

Colors |

Transparent, Opal, Green, Blue, Red, Bronze and Customized |

||

|

Warranty |

10 years |

||

Key Characteristics and Advantages of Polycarbonate Facade Panels

product Advantages

PC Plug-Pattern Sheet application

● Facades: The plug-pattern design and enhanced strength of 7 wall X structure Sheets make them suitable for facade applications. They can be used to create visually appealing and durable exterior surfaces for buildings.

● Internal Partitions: 7 Walls X structure Polycarbonate facade panels can be used as partitions to divide interior spaces. They provide privacy while still allowing light to pass through, creating a bright and open atmosphere.

● External Wall Cladding: These sheets can be used as external wall cladding to enhance the aesthetics and durability of buildings. The plug-pattern design adds visual interest to the facade.

PC Plug-Pattern Sheet Features

● Coefficient of linear expansion: 0.065 MM/M℃

● Fire retardant level: GB8624, B1

● No thermal expansion

● 100% water leakage proof

● High light transmittance

● Can withstand extremely high loads

● Double-sided UV protection

● High thermal insulation performance

● Suitable for bending design

● Intelligent light control system

● Simple and fast installation

PC Plug-Pattern Sheet STRUCTURE

Four wall rectangular structure, seven wall rectangular structure, seven wall X structure, ten wall structure.

Plug-Pattern Design: The plug-pattern design of these sheets consists of small plugs or protrusions on the surface, which helps to enhance the structural integrity and stability of the sheet.

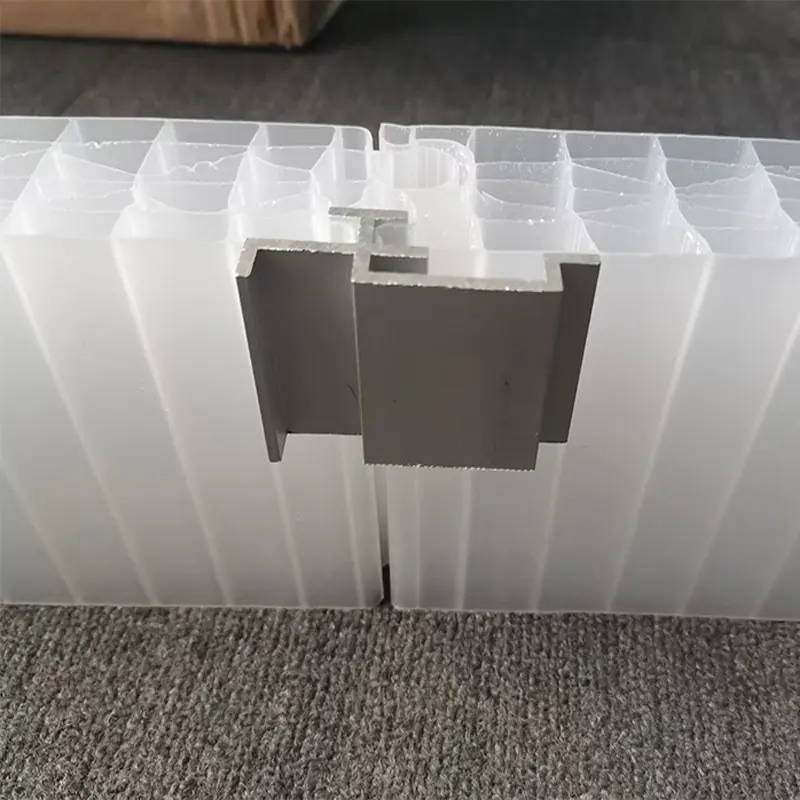

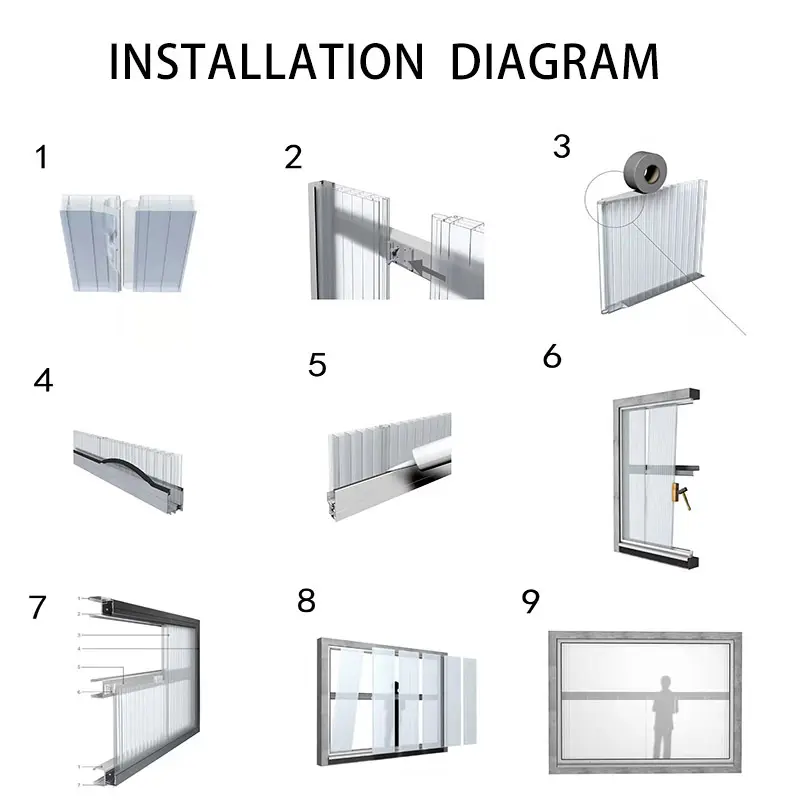

PC Plug-Pattern Sheet installation

For minimizing the infltration of dust particles into the chambers of the panels, the panel ends have to be sealed carefulyThe upper panel end and lower end must be tightly sealed with Anti-Dust-Tape.

*For minimizing the infltration of dust particles into the chambers of the panels, the panel ends have to be sealed carefullyThe upper panel end and lower end must be tightly sealed with Anti-Dust-Tape. lt is important that tongue and groove jointof the panels are also sealed completely and carefully.

*The protective film of the panels must be removed in areas of taping. lt must be ensured that remove the protective filmfrom all around about 6cm when the panels are set into the frame profile.

*The fastener must be positioned at the horizontal bar and must be pushed against the panel. The fastener must be fixedwith at least two screws at the crossbar.

*Depending on panel length,it is necessary to use hammer and softwood to interlock the panels.

*Take care that the fastenersare positioned exactly inside the notches of the panels.

*PC material isespecially avoided to use.After finish installation, remove the panel's protective foil.

Why choose us?

ABOUT MCLPANEL

Our advantage

FAQ

Company Introduction

Shanghai mclpanel New Materials Co., Ltd. has a wide selection of solid polycarbonate sheet to suit your needs. Mclpanel has been dominating the solid polycarbonate sheet market owing to the core technology to produce the finest products. By providing the best quality and professional service, Shanghai mclpanel New Materials Co., Ltd. hopes building more cooperation relationship with every customer. Please contact us!

Do not hesitate to contact us if you are interested in ourPolycarbonate Solid Sheets,Polycarbanote Hollow Sheets,U-Lock Polycarbonate,plug in polycarbonate sheet,Plastic Processing,Acrylic Plexiglass Sheet.