Focus on PC/PMMA sheet production and processing jason@mclsheet.com +86-187 0196 0126

Translucent polycarbonate signage advertising cladding panel for wall materials

Polycarbonate signage advertising cladding panels are an excellent choice for businesses looking to create impactful and durable displays. Their offer a combination of durability, versatility, and aesthetic appeal, making them a smart choice for effective advertising and branding.

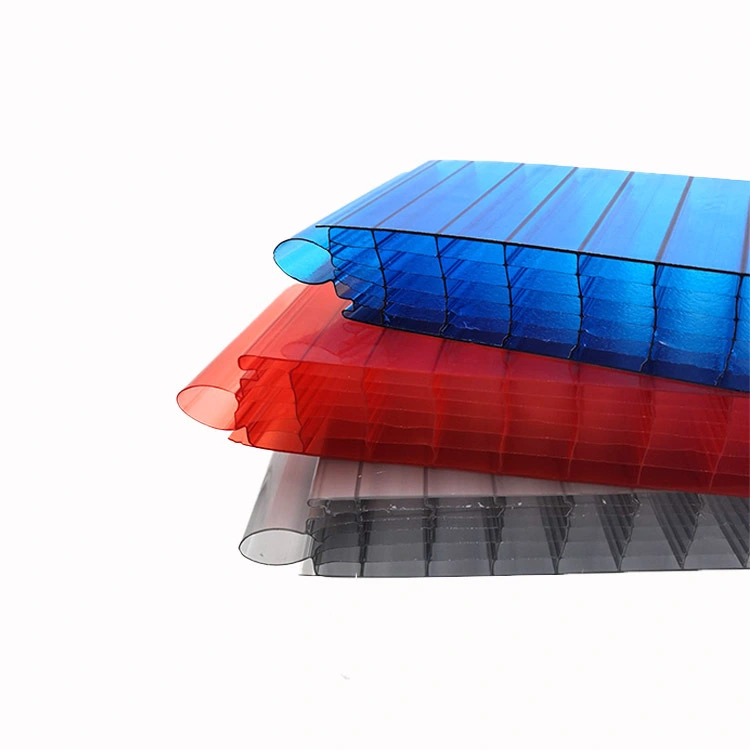

Product name: Polycarbonate plug-pattern sheets

Width: 500mm and 800mm

Thickness: 30mm 40mm or 50mm

Color: Clear, Opal, Blue, Lake Blue, Green, Bronze, or Customized

Length: Customized

Structure: Four wall rectangular, 7 wall X structure, 7 wall rectangular.

Product Description

Plug-Pattern Design: The plug-pattern design of these sheets consists of small plugs or protrusions on the surface, which helps to enhance the structural integrity and stability of the sheet.

X Structure: The X structure of these sheets provides increased strength and rigidity compared to standard multi-wall polycarbonate sheets. This makes them more resistant to impacts and bending .

Lightweight: Significantly lighter than glass, making it easier to handle and install.

UV Protection: Typically treated to resist UV radiation, preventing yellowing and degradation over time.

Polycarbonate Plug-Pattern Sheet are a versatile and attractive choice for a variety of applications, from architectural elements to lighting solutions. Their combination of durability, lightweight properties, and aesthetic design makes them ideal for both functional and decorative uses.

Common Applications

Polycarbonate facade wall panels have a wide range of applications due to their unique properties, such as architecture, construction, transportation, signage, and interior design. They are often used for partitions, skylights, lighting fixtures, protective barriers, decorative elements, and other applications where a combination of strength, transparency, and visual aesthetics is desired.

product parameters

|

Item |

Thickness |

Width |

Length |

|

Polycarbonate Plug-Pattern Panel |

30/40 mm |

500 mm |

5800 mm |

|

Raw Material |

100% virgin Bayer/ Sabic |

||

|

Density |

1.2 g/cm³ |

||

|

Profiles |

7-Wall Rectangle/ X Structure |

||

|

Colors |

Transparent, Opal, Green, Blue, Red, Bronze and Customized |

||

|

Warranty |

10 years |

||

Key Characteristics and Advantages of Polycarbonate Facade Panels

product Advantages

Plug-Pattern Sheet STRUCTURE

Product installation

For minimizing the infltration of dust particles into the chambers of the panels, the panel ends have to be sealed carefulyThe upper panel end and lower end must be tightly sealed with Anti-Dust-Tape. lt is important that tongue and groove jointof the panels are also sealed completely and carefully.

1.The protective film of the panels must be removed in areas of taping. lt must be ensured that remove the protective filmfrom all around about 6cm when the panels are set into the frame profile.

2.There must be an expansion joint of approx. 3-5mm in between(this value is valid for an installation temperature of +20 degree)

3.The fastener must be positioned at the horizontal bar and must be pushed against the panel. The fastener must be fixedwith at least two screws at the crossbar.

4.Depending on panel length,it is necessary to use hammer and softwood to interlock the panels.

5.Take care that the fastenersare positioned exactly inside the notches of the panels.

6.The gasket must be pressed directly tightly onto the front panel so it is put under tension and fixed.Chemical resistance of polvcarbonate against other chemicals used are to be checked by customer on site.

Why choose us?

ABOUT MCLPANEL

Our advantage

FAQ