Focus on PC/PMMA sheet production and processing jason@mclsheet.com +86-187 0196 0126

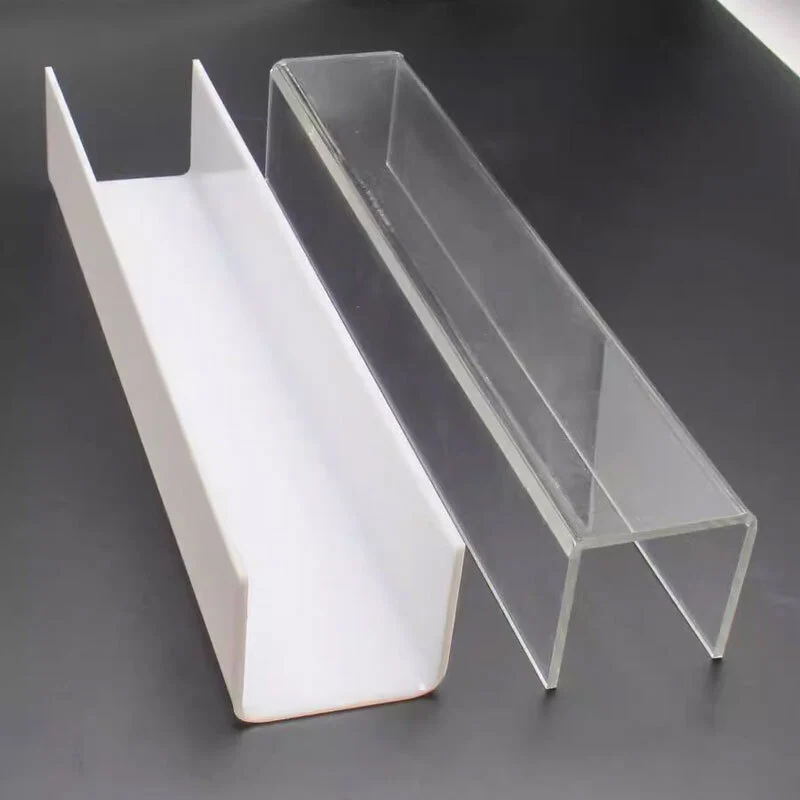

Acrylic folded parts fabricated shapes transparent by precision processing for covers

This custom-designed acrylic protective cover is engineered to safeguard delicate mechanical components, electronics, or other sensitive equipment from environmental factors, such as dust, debris, and accidental impacts. Crafted from high-quality transparent acrylic, the cover features a sleek and modern design that allows the protected items to be clearly visible while maintaining a physical barrier. With its sturdy construction and precision-fit, this acrylic mechanical protective cover is an essential solution for protecting valuable machinery and equipment.

Product Name: Acrylic mechanical protective cover

Thickness: 1mm-10mm, Customized

Size: Custom

Usage: Industrial Machinery,Electronic Equipment

Warranty: 10 years

Product Description

This custom-designed acrylic protective cover is engineered to safeguard delicate mechanical components, electronics, or other sensitive equipment from environmental factors, such as dust, debris, and accidental impacts. Crafted from high-quality transparent acrylic, the cover features a sleek and modern design that allows the protected items to be clearly visible while maintaining a physical barrier. With its sturdy construction and precision-fit, this acrylic mechanical protective cover is an essential solution for protecting valuable machinery and equipment.

Industrial Machinery: Use the acrylic protective cover to safeguard sensitive components, motors, or control panels in manufacturing environments.

Electronic Equipment: Protect delicate electronic devices, circuit boards, or testing equipment from dust, debris, and physical damage.

Automotive Components: Secure and protect critical automotive parts, such as engine components or electronic systems, during transportation or storage.

This custom-built acrylic mechanical protective cover is an essential solution for businesses, technicians, and researchers seeking to safeguard their valuable equipment and machinery from environmental factors and physical damage, while maintaining visibility and accessibility.

product parameters

|

Characterics |

Unit |

Data |

|

Impact strength |

J/m |

88-92 |

|

Light transmission |

% |

50 |

|

Specify Gravity |

g/m |

1.2 |

|

Elongation at break |

% |

≥130 |

|

Coefficient thermal expansion |

mm/m℃ |

0.065 |

|

Service temperature |

℃ |

-40℃~+120℃ |

|

Heat conductively |

W/m²℃ |

2.3-3.9 |

|

Flexural strength |

N/mm² |

100 |

|

Modulus of elasticity |

Mpa |

2400 |

|

Tensile strength |

N/mm² |

≥60 |

|

Soundproof index |

dB |

35 decibel decrease for 6mm solid sheet |

All andvantage you need to know about us

Product application

Industrial Machinery: Use the acrylic protective cover to safeguard sensitive components, motors, or control panels in manufacturing environments.

Electronic Equipment: Protect delicate electronic devices, circuit boards, or testing equipment from dust, debris, and physical damage.

Laboratory Instruments: Utilize the cover to shield analytical instruments, scientific equipment, or research setups from external contaminants.

Art Galleries and Museums: Use the acrylic cover to protect and display valuable artworks, sculptures, or other fragile exhibits.

Office Environments: Safeguard important documents, certificates, or delicate office decor with the sleek and protective acrylic cover.

Retail Displays: Enhance the presentation of your products or displays while keeping them secure with the transparent acrylic cover.

Home Decor: Utilize the protective cover to showcase and preserve your cherished photographs, collectibles, or decorative items.

Educational Institutions: Protect educational displays, models, or laboratory equipment with the durable acrylic cover.

Other processes

● Drilling: Holes and openings can be created in PC boards using drilling techniques.

● Bending and Forming: PC boards can be bent and formed into desired shapes using heat.

● Thermoforming: Thermoforming is a process where a heated PC sheet is placed over a mold and then vacuum or pressure is applied to shape the material to match the mold contours.

● CNC Milling: CNC milling machines equipped with appropriate cutting tools can be used to mill PC boards

● Bonding and Joining: PC boards can be bonded or joined together using various methods

● Surface Finishing: PC boards can be finished to enhance their appearance or provide specific functionalities.

Why choose us?

ABOUT MCLPANEL

Our advantage

FAQ