Focus on PC/PMMA sheet production and processing jason@mclsheet.com +86-187 0196 0126

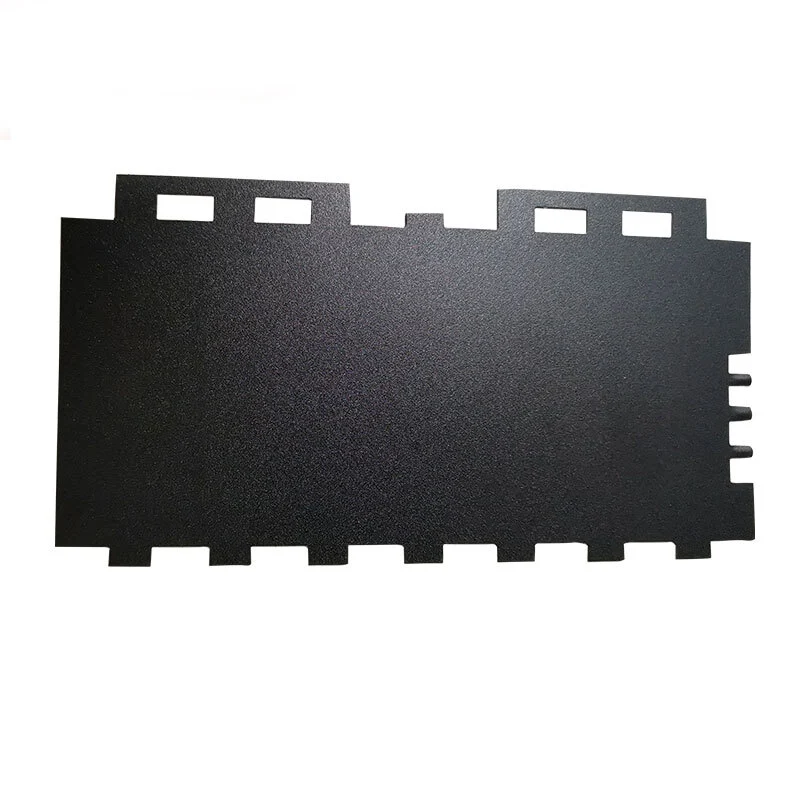

Black Polycarbonate Insulation Film With UL94 V0 Flame Retardant For Electric Component

PC insulation film is a one side matte, one side velvet flame-retardant polycarbonate film with a UL94 V-0 listing at 0.250 mm-1mm. VTM-0 at 0.1mm -0.25mm.This film has formability, excellent mechanical properties, good dimensional stability at high temperatures and a high flammability rating.

Product Name: Polycarbonate insulation film

Thickness: 0.1mm-0.5mm, customized

Width: MAX 2000mm, custom

Length: custom

Warranty: 2 years

Product Description

Unleashing the Potential of Polycarbonate Insulation Films

PC insulation film is good for applications such as power supply insulation, disc drive insulation, bus-bar insulation, TV/monitor insulation, PC board insulation, business equipment insulation and has insulation and EMI/RFI shielding when laminated with metal foil.

Polycarbonate insulation film is a versatile material known for its excellent thermal insulation properties, durability, and lightweight characteristics. Here are some key features and applications:

Key Features:

Thermal Insulation: Polycarbonate insulation film effectively reduces heat transfer, making it ideal for energy-efficient applications.

Impact Resistance: It is highly durable and resistant to impact, providing protection in various environments.

Lightweight: Compared to glass, polycarbonate is significantly lighter, making it easier to handle and install.

UV Protection: Many polycarbonate films come with UV-blocking properties, protecting interiors from harmful rays and reducing fading of materials.

Flexibility: The film can be easily cut and shaped, allowing for customized applications.

These properties make polycarbonate film an essential material in the design and manufacturing of electronic products. Customers across diverse industries, from electronics to transportation, rely on our high-quality polycarbonate thin film solutions to elevate their products, enhance user experiences, and meet the ever-evolving demands of the market.

product parameters

|

Characterics |

Unit |

Data |

|

Impact strength |

J/m |

88-92 |

|

Light transmission |

% |

50 |

|

Specify Gravity |

g/m |

1.2 |

|

Elongation at break |

% |

≥130 |

|

Coefficient thermal expansion |

mm/m℃ |

0.065 |

|

Service temperature |

℃ |

-40℃~+120℃ |

|

Heat conductively |

W/m²℃ |

2.3-3.9 |

|

Flexural strength |

N/mm² |

100 |

|

Modulus of elasticity |

Mpa |

2400 |

|

Tensile strength |

N/mm² |

≥60 |

|

Soundproof index |

dB |

35 decibel decrease for 6mm solid sheet |

Custom thickness 0.1mm-0.5mm

At our advanced manufacturing facility, we specialize in the production of high-performance polycarbonate (PC) thin films.

These versatile materials, available in thicknesses ranging from 0.05mm to 0.5mm, offer a unique combination of optical clarity, mechanical durability, and dimensional stability.

UL94 V0 Flame Retardant

Polycarbonate film can quickly extinguish after burning, achieving flame retardant levels of V0-V2, which is suitable for various insulation applications.

Product application

Polycarbonate insulation film is widely used in electrical components due to its excellent insulating properties and durability. Here are some key applications:

Insulating Barriers: Used to create insulating layers between conductive parts in electrical assemblies, preventing short circuits.

Flexible Printed Circuits (FPCs): Serves as a substrate in flexible PCBs, providing insulation and support for electronic components.

Capacitors and Transformers: Acts as an insulating layer in capacitors and transformers, enhancing performance and safety.

Wire and Cable Insulation: Employed as an insulation layer for wires and cables, protecting against electrical interference and physical damage.

Circuit Board Protection: Used to coat and protect circuit boards from moisture, dust, and mechanical stress.

Switchgear and Relays: Provides insulation in switchgear and relays, ensuring safe operation under high voltage conditions.

Light Fixtures: Utilized in electrical light fixtures to insulate and protect internal components from heat and electrical interference.

Battery Insulation: Used in battery packs to provide electrical insulation and thermal stability, enhancing safety and performance.

Why choose us?

ABOUT MCLPANEL

Our advantage

FAQ