Xoogga saar PC / PMMMA xaashida iyo howsha jason@mclsheet.com +86-187 0196 0126

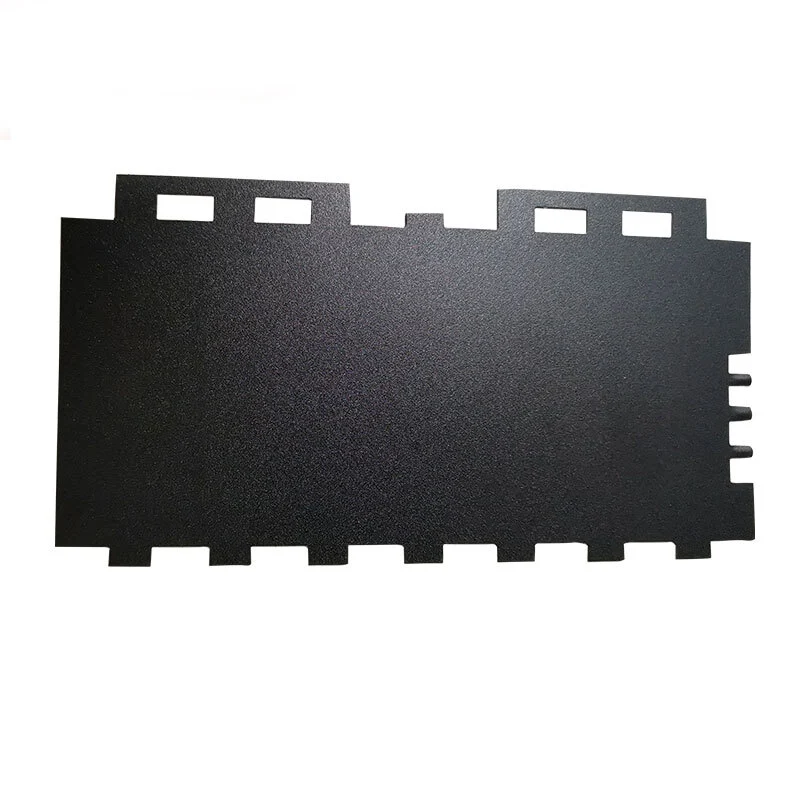

Filimka Dahaarka Madow ee Polykarbonate leh UL94 V0 Dab-demiska Qaybaha Korontada

Filimka dahaarka PC-ga waa matte hal dhinac ah, hal dhinac oo dab-demiska polycarbonate ah oo leh UL94 V-0 oo ku taxan 0.250 mm-1mm. VTM-0 at 0.1mm -0.25mm.Filimkani wuxuu leeyahay qaab-dhismeedka, sifooyinka farsamada ee aad u fiican, xasilloonida cabbirka wanaagsan ee heerkulka sare iyo qiimeynta ololka sare

Magaca duwanka: Polycarbonate filimka dahaarka

Qowlka: 0.1mm-0.5mm, la habeeyay

Ballaca: MAX 2000mm, caado

Geeridka: caado

Warrante: 2 Sano

Tilmaada

Sii daynta Suuragalnimada Filimada Insulation Polycarbonate

Filimka kombuyuutarku wuxuu u fiican yahay codsiyada sida dahaarka korantada, dahaarka wadista disc, dahaarka baska, TV/kormeeraha, dahaadhka guddiga PC, dahaadhka qalabka ganacsiga wuxuuna leeyahay dahaar iyo gaashaan EMI/RFi marka lagu dhejiyo birta birta ah.

Filimka dahaarka polycarbonate waa walxo badan oo caan ku ah sifooyinka kuleylka kuleylka, adkeysiga, iyo sifooyinka fudud. Waa kuwan qaar ka mid ah astaamaha muhiimka ah iyo codsiyada:

Sifurada:

Xakamaynta kulaylka: Filimka daboolka polycarbonate wuxuu si wax ku ool ah u yareeyaa kulaylka, taas oo ka dhigaysa mid ku habboon codsiyada tamarta waxtarka leh.

Iska caabbinta Saamaynta: Aad bay u adkeystaa una adkaysataa saamaynta, iyadoo bixisa ilaalin deegaanno kala duwan.

Miisaanka Fudud: Marka loo eego galaaska, polycarbonate si weyn ayuu uga fudud yahay, taas oo sahlaysa in la qabto oo la rakibo.

Ilaalinta UV: Aflaan badan oo polycarbonate ah waxay la yimaadaan sifooyin UV-blocking, ka ilaalinta gudaha gudaha fallaadhaha waxyeelada leh iyo yaraynta qallafsanaanta alaabta.

Dabacsanaan: Filimku si fudud ayaa loo jari karaa loona qaabayn karaa, taas oo u oggolaanaysa codsiyada la habeeyey.

Qalabkan ayaa ka dhigaya filimka polycarbonate mid muhiim u ah naqshadeynta iyo soo saarista alaabta elektiroonigga ah. Macaamiisha warshado kala duwan, laga bilaabo elektiroonigga ilaa gaadiidka, waxay ku tiirsan yihiin xalalkayaga filimaanta khafiifka ah ee polycarbonate ee tayada sare leh si ay kor ugu qaadaan alaabtooda, kor u qaadaan khibradaha isticmaale, oo ay u daboolaan baahida suuqa ee weligeed soo kordheysa.

xuduudaha alaabta

Astaamaha | Waad | Xogta |

Awood saamayn | J/m | 88-92 |

Gudbinta iftiinka | % | 50 |

Cufis-jiidad gaar ah | g/m | 1.2 |

Dheeraynta xilliga nasashada | % | ≥130 |

Kordhinta kulaylka isku-dhafka ah | mm/m℃ | 0.065 |

Heerkulka adeega | ℃ | -40℃~+120℃ |

Kuleyl si habaysan | W/m²℃ | 2.3-3.9 |

Xoog dabacsanaan | N/mm² | 100 |

Hababka bartinimada | Mpa | 2400 |

Xoog xajin | N/mm² | ≥60 |

Tusiyaha aan codka lahayn | dB | 35 decibel hoos u dhac 6mm xaashi adag |

Dhumucda gaarka ah 0.1mm-0.5mm

Xaruntayada wax soo saarka ee horumarsan, waxaanu ku takhasusay soo saarista filimada khafiifka ah ee polycarbonate (PC).

Agabkaan kala duwan, ee laga heli karo dhumucyada u dhaxeeya 0.05mm ilaa 0.5mm, waxay bixiyaan isku darka cad ee indhaha, adkeysiga farsamada, iyo xasilloonida cabbirka.

UL94 V0 Ololka Retardant

Filimka Polycarbonate wuxuu si dhakhso ah u damin karaa gubashada ka dib, isagoo gaaraya heerar dab-damis ah oo V0-V2 ah, kaas oo ku habboon codsiyada dahaarka ee kala duwan.

Codsiga alaabta

Filimka dahaarka polycarbonate ayaa si weyn loogu isticmaalaa qaybaha korantada sababtoo ah sifooyinka wanaagsan ee ilaalinta iyo cimri dhererka. Waa kuwan qaar ka mid ah codsiyada muhiimka ah:

Caqabadaha Dahaarka: Waxaa loo isticmaalaa in lagu abuuro lakabyo dahaadh ah oo u dhexeeya qaybaha korantada ee shirarka korantada, ka hortagga wareegyada gaaban.

Wareegyada Daabacan ee Dabacsan (FPCs): Wuxuu u adeegaa sidii substrate PCB-yada dabacsan, isagoo siiya dahaarka iyo taageerada qaybaha elektiroonigga ah.

Capacitors iyo Transformers: Waxay u shaqeeyaan sidii lakab dahaarka ee capacitors iyo Transformers, kor u qaadaya waxqabadka iyo badbaadada.

Wire and Cable Insulation: Waxaa loo shaqeeyaa sidii lakabka dahaarka ee fiilooyinka iyo fiilooyinka, ka ilaalinta faragelinta korantada iyo dhaawaca jirka.

Ilaalinta Guddiga Wareegga: Waxaa loo isticmaalaa in lagu daboolo oo laga ilaaliyo looxa wareegga qoyaanka, boodhka, iyo walbahaarka farsamada.

Qalabka Bedesha iyo Relays: Waxay ku siisaa dahaarka wareegyada iyo relaysyada, iyagoo hubinaya hawlgal badbaado leh oo hoos yimaada xaaladaha danab sare.

Qalabka Iftiinka: Waxaa loo adeegsadaa qalabka laydhka ee korantada si looga ilaaliyo ugana ilaaliyo qaybaha gudaha kulaylka iyo faragelinta korantada.

Dahaarka baytariga: Waxaa loo isticmaalaa baakadaha batteriga si loo bixiyo dahaarka korantada iyo xasiloonida kulaylka, kor u qaadista badbaadada iyo waxqabadka.

Maxaa noo doora?

Ku dhiirigeli dhismaha hal-abuurka leh ee MCLpanel

MCLpanel waa xirfad-yaqaan wax-soo-saarka polycarbonate, goynta, xirmada iyo rakibidda. Kooxdayadu waxay had iyo jeer kaa caawiyaan inaad hesho xalka ugu fiican.

ABOUT MCLPANEL

Kaalmadana

FAQ