Focus on PC/PMMA sheet production and processing jason@mclsheet.com +86-187 0196 0126

4mm Solid Polycarbonate Sheet Highly Rated

Product details of the 4mm solid polycarbonate sheet

Product Description

Mclpanel 4mm solid polycarbonate sheet is high-quality and with an innovative design. The product has high interior quality due to continuous technology innovations. Over the years, the product continues to upgrade and get the praise of the majority of users.

Product Description

Polycarbonate Anti-fog polycarbonate solid sheets are a specialized variant of the durable and impact-resistant polycarbonate material, designed to excel in environments where maintaining clear visibility is critical. These sheets combine the superior physical properties of solid polycarbonate construction with advanced anti-fog technology, ensuring unobstructed sight lines and enhanced functionality in a wide range of applications.

Key Characteristics of Anti-Fog Polycarbonate Solid Sheets:

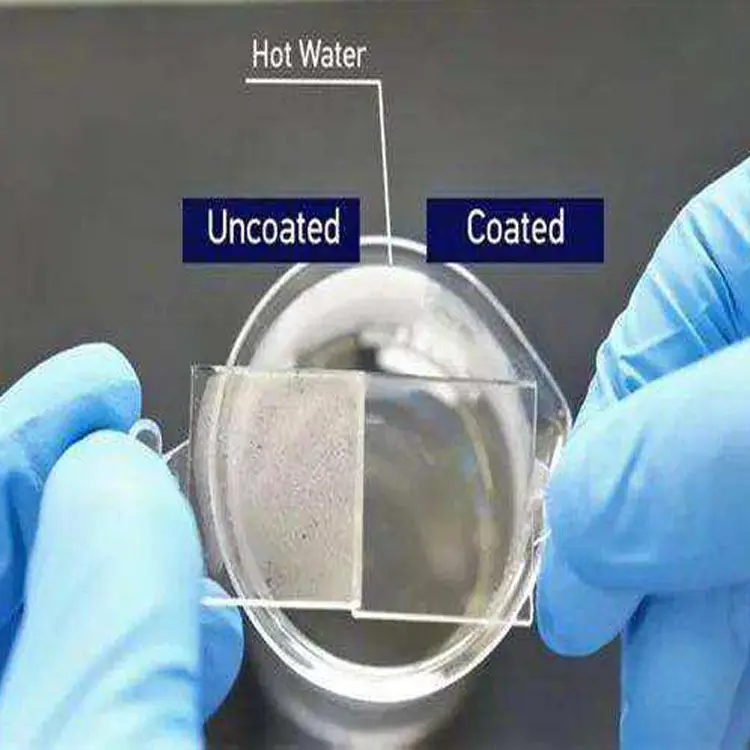

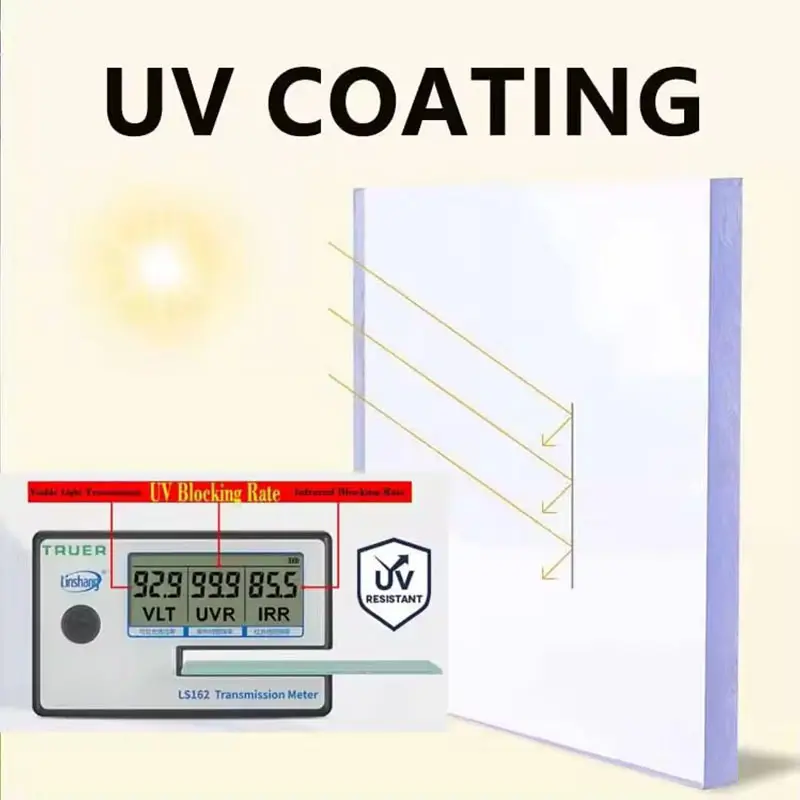

Anti-Fog Coating or Treatment:

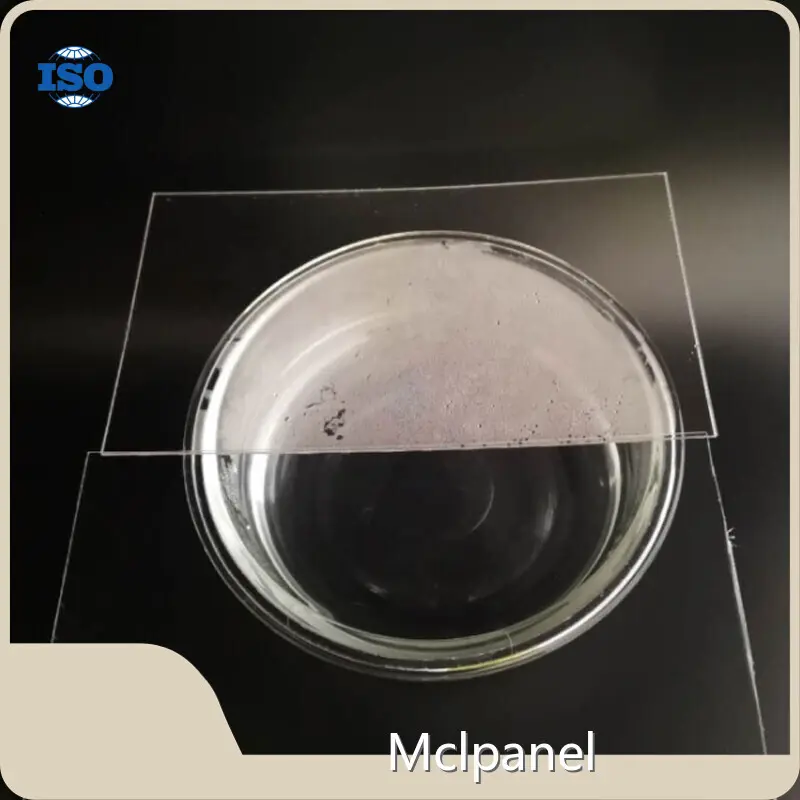

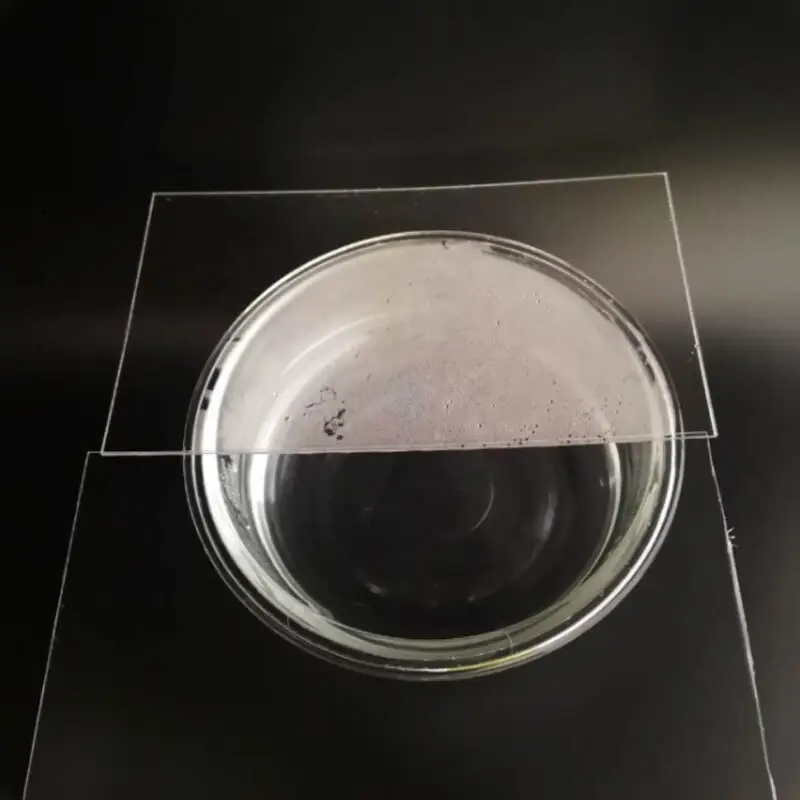

The surface of these polycarbonate solid sheets is treated or coated with a specialized anti-fog formula, which prevents the formation of water droplets and condensation.

The anti-fog mechanism promotes the even spread of water molecules across the sheet's surface, rather than allowing them to coalesce into larger, obstructive droplets.

Optical Clarity and Transparency:

Anti-fog polycarbonate solid sheets maintain the inherent optical clarity and transparency of standard solid polycarbonate materials, ensuring unobstructed visibility and light transmission.

The anti-fog treatment does not compromise the sheet's light transmittance or visual clarity, making it an ideal choice for applications where clear visibility is essential.

Durability and Impact Resistance:

Anti-fog polycarbonate solid sheets retain the exceptional durability, impact resistance, and weatherability of standard solid polycarbonate materials.

They can withstand a wide range of environmental conditions, including UV exposure, temperature fluctuations, and physical impacts, making them suitable for both indoor and outdoor applications.

Anti-Fog solid polycarbonate sheets offer a versatile and durable solution for a wide range of applications, from architectural elements to industrial and commercial settings. Their combination of impact resistance, optical clarity, and design flexibility make them a valuable choice for designers, architects, and manufacturers seeking a high-performance building material.

Regardless of the thickness, our transparent PC sheets are manufactured to the highest standards, leveraging advanced production techniques to deliver materials with consistent quality and optical properties. Customers across diverse industries rely on these thin-profile polycarbonate solutions to elevate their designs and enhance the visual experience for end-users.

product parameters

|

Characterics |

Unit |

Data |

|

Impact strength |

J/m |

88-92 |

|

Light transmission |

% |

50 |

|

Specify Gravity |

g/m |

1.2 |

|

Elongation at break |

% |

≥130 |

|

Coefficient thermal expansion |

mm/m℃ |

0.065 |

|

Service temperature |

℃ |

-40℃~+120℃ |

|

Heat conductively |

W/m²℃ |

2.3-3.9 |

|

Flexural strength |

N/mm² |

100 |

|

Modulus of elasticity |

Mpa |

2400 |

|

Tensile strength |

N/mm² |

≥60 |

|

Soundproof index |

dB |

35 decibel decrease for 6mm solid sheet |

Product advantages

Product application

Safety and Personal Protective Equipment (PPE):

Face shields, goggles, and visors

Protective barriers and partitions

Sneeze guards and transparent enclosures

Transportation and Automotive:

Windshields, side windows, and sunroofs

Instrument panel covers and display screens

Protective covers for transportation equipment

Medical and Healthcare:

Observation windows and panels in medical facilities

Protective barriers and partitions in healthcare settings

Incubator and equipment covers

Food Service and Hospitality:

Sneeze guards and food service partitions

Display cases and countertops

Shower and bathroom enclosures

Industrial and Commercial Settings:

Machine guards, safety shields, and enclosures

Display cases, signage, and point-of-sale elements

Protective covers and guards for equipment

COLOR

Clear/Transparent:

- This is the most common and popular option, offering maximum light transmission and optical clarity

- Transparent PC sheets are widely used for glazing, skylights, and other applications where clear visibility is desired

Tinted:

- Polycarbonate sheets can be produced with various tinted or colored options

- Common tint colors include smoke gray, bronze, blue, green, and amber

- Tinted PC sheets can be used to provide glare reduction, enhanced privacy, or specific aesthetic effects

Opal/Diffused:

- Opal or diffused polycarbonate sheets have a translucent, milky appearance

- They provide a soft, even light diffusion, reducing direct glare and hot spots

- Opal PC sheets are often used for lighting fixtures, partitions, and other applications requiring diffused illumination

PRODUCT INSTALLTION

Prepare the Installation Area:

Gather the Necessary Tools and Materials:

Install the Supporting Structure:

Cut and Prepare the Polycarbonate Sheets:

Why choose us?

ABOUT MCLPANEL

Our advantage

FAQ

Company Advantage

• Our company actively develops domestic and international market and builds relevant sales channels according to the market position of the products.

• Time passed quickly. Mclpanel has passed a difficult and hard time of years unconsciously. Over the years, we keep pursuing our dreams and constantly realizing self breakthrough.

• Unique geographical advantages and abundant social resources create good conditions for Mclpanel's development.

• Mclpanel has built a service system that meets the needs of consumers. It has won wide acclaim and support from customers.

Hello, welcome to Mclpanel's official website! If you have any needs, please call us. We will sincerely provide you with the most professional service.