Focus on PC/PMMA sheet production and processing jason@mclsheet.com +86-187 0196 0126

Wear scratch resistant polycarbonate sheet 2H hardness for display covers

Scratch-resistant polycarbonate sheets are a specialized type of polycarbonate material that features a hard coating on one or both surfaces to enhance durability and prevent scratches, abrasions, and surface wear. These sheets retain the high impact resistance, lightweight, and clarity of standard polycarbonate while offering improved surface protection, making them suitable for demanding environments where durability and optical clarity are essential.

Product name: Scratch-resistant polycarbonate sheets

size: 1220mm*2440mm or Customized

Thickness: 2mm 3mm 5mm 8mm 10mm 20mm 30mm

Color: Clear, or Customized

Surface Hardness: HB to 3H

Product Description

Scratch-resistant polycarbonate sheets are ideal materials for applications requiring high strength, transparency, and scratch resistance. Whether in construction, automotive, or electronics, they offer superior performance and safety benefits.

product parameters

|

Name |

Scratch Resistant acrylic sheets |

|

Thickness |

1.8, 2, 3, 4, 5, 8,10,15,20, 30mm (1.8-30mm) |

|

Color |

Transparent or custom |

|

Standard size |

1220*2440, 1050*2050, 2050*3050mm |

|

Certificate |

CE, SGS, DE, and ISO 9001 |

|

Surface Hardness |

HB to 3 H |

|

MOQ |

2 tons, can be mixed with colors/sizes/thickness |

|

Delivery |

10-25 days |

Production Process

The manufacture of scratch-resistant polycarbonate sheets involves a specialized process to enhance the surface durability and abrasion resistance of the material. The key steps in this production process are as follows:

Raw Material Preparation:

The primary raw material is acrylic resin, which provides the base material for the sheets.

Scratch-resistant additives, such as hard inorganic particles or specialized coatings, are also carefully measured and prepared for incorporation into the acrylic.

Compounding:

The polycarbonate resin and scratch-resistant additives are fed into a high-intensity mixer or extruder, where they are thoroughly blended and homogenized.

This compounding process ensures a uniform distribution of the scratch-resistant additives throughout the acrylic matrix.

Extrusion:

The compounded polycarbonate material is then fed into a specialized extruder equipped with precise temperature and pressure controls.

The extruder melts and forces the acrylic compound through a die, shaping it into a continuous sheet or film.

Surface Treatment:

Depending on the specific scratch-resistant technology used, the extruded polycarbonate sheet may undergo an additional surface treatment process.

This can involve the application of a protective coating, either through a separate coating step or an in-line coating process integrated into the extrusion line.

custom to size

Cutting:

- Cutting to Size: Polycarbonate sheets can be cut to the desired size using various methods, such as:

- Circular saws or table saws with fine-toothed blades designed for plastics

- CNC (Computer Numerical Control) routers or laser cutters for precise, custom shapes

- Manual scoring and snapping for simple straight-line cuts

- Cutting to Size: Polycarbonate sheets can be cut to the desired size using various methods, such as:

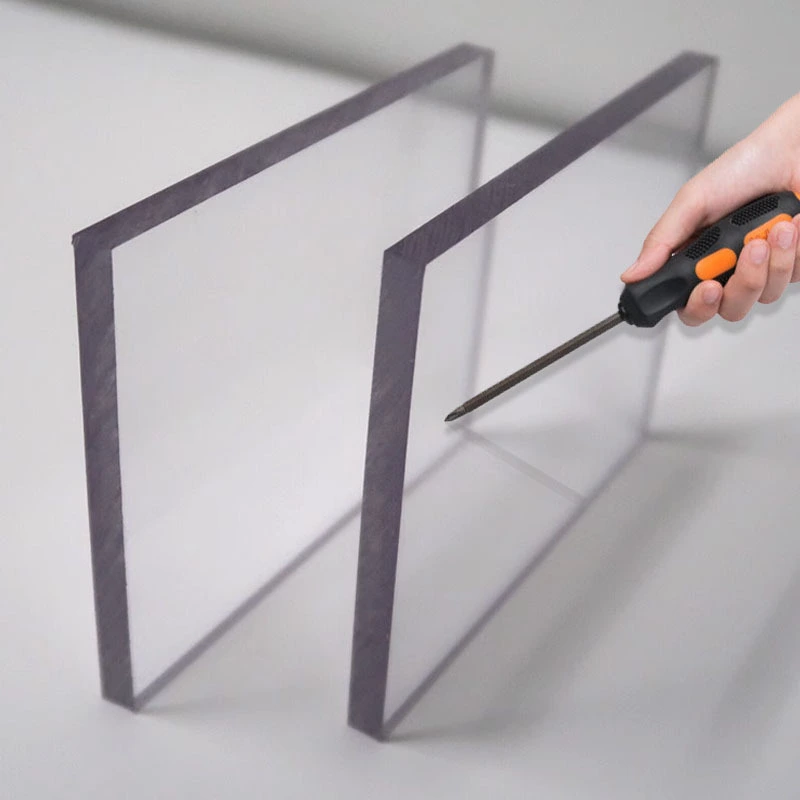

Trimming and Edging:

- Edge Finishing: The edges of the cut acrylic sheets can be finished using techniques like:

- Grinding or sanding to smooth the edges

- Applying edge treatments, such as decorative edge moldings or polished edges

- Edge Finishing: The edges of the cut acrylic sheets can be finished using techniques like:

Drilling and Punching:

- Holes and Openings: acrylic sheets can be drilled or punched to create holes, slots, or other openings as required for the application.

- Specialized drill bits and punches designed for plastics are typically used to prevent cracking or chipping.

Thermoforming:

- Complex Shapes: acrylic sheets can be thermoformed into various three-dimensional shapes, such as curved or contoured panels, using specialized molds and heating equipment.

- This process allows for the creation of custom-shaped parts from flat sheets.

Product application

Security and Safety

Protective barriers, partitions, and enclosures that require both clarity and durability.

Bulletproof or shatterproof panels for banks, prisons, or security checkpoints.

Transportation

Vehicle windows, windshields, and sunroofs for cars, buses, and trains.

Protective shields for motorcycles or airplanes.

Retail and Commercial Displays

Durable display cases, shelving, and signage for stores or exhibitions.

Anti-scratch surfaces for point-of-sale systems and kiosks.

Electronics and Technology

Screen protectors, electronic display covers, and panels for touchscreen devices.

Enclosures for sensitive equipment in industrial settings.

Medical and Laboratory Use

Protective barriers and sneeze guards in hospitals and labs.

Durable, scratch-resistant covers for sensitive instruments.

Why choose us?

ABOUT MCLPANEL

Our advantage

FAQ