Focus on PC/PMMA sheet production and processing jason@mclsheet.com +86-187 0196 0126

6mm Solid Polycarbonate Sheet Mclpanel Brand

Product details of the 6mm solid polycarbonate sheet

Quick Detail

Innovative design concept: From appearance to construction, Mclpanel 6mm solid polycarbonate sheet is designed by our professional designers. They discuss to each other to ensure that each design has the innovative characteristics of industrial standard. Customers are greatly satisfied with the function of the product. The 6mm solid polycarbonate sheet produced by Mclpanel is of high quality and is widely used in the industry. With the fast development of the industry, the demand of the product is further increased.

Product Description

Compared with other products in the same category, 6mm solid polycarbonate sheet has the following competitive advantages.

Product Description

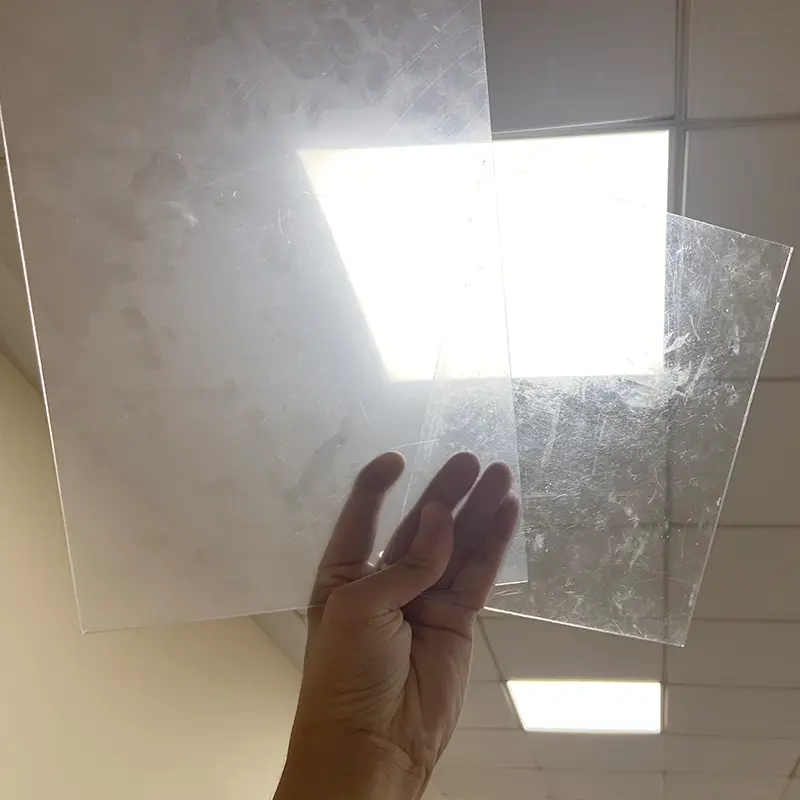

Anti-reflective polycarbonate sheets are a specialized variant of the popular polycarbonate material that have been engineered to reduce glare and reflections, ensuring enhanced optical performance and improved visibility in a wide range of applications. These sheets combine the durability, impact resistance, and optical clarity of standard polycarbonate with advanced anti-reflective coatings or treatments, making them a valuable choice for environments where minimizing glare and maximizing clarity are critical.

Key Characteristics of Anti-Reflective Polycarbonate Sheets:

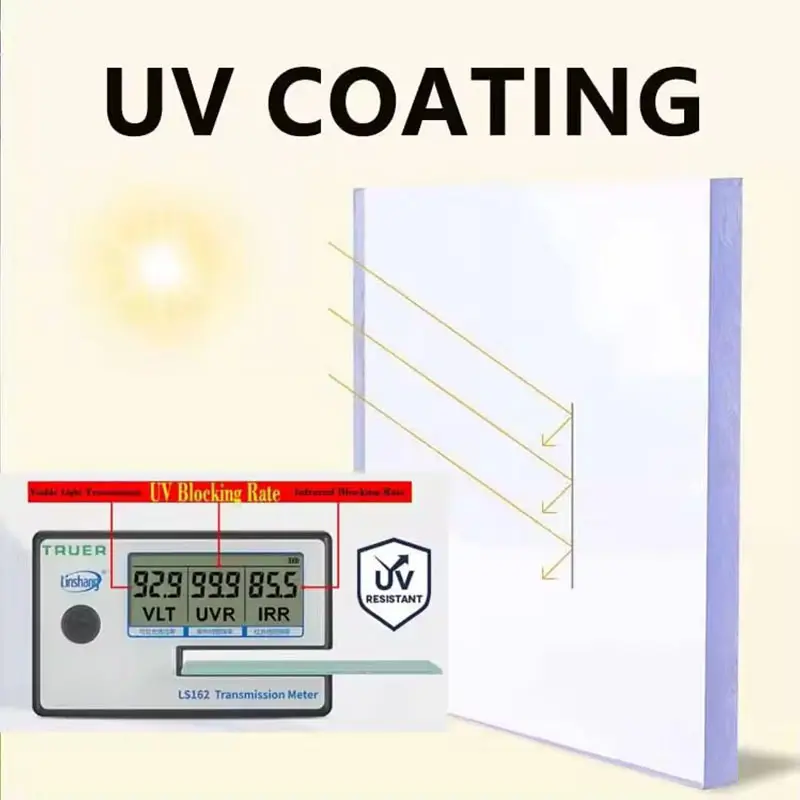

Anti-Reflective Coatings or Treatments:

Anti-reflective polycarbonate sheets feature a specialized coating or treatment applied to one or both surfaces of the sheet.

These coatings are designed to reduce the amount of light that is reflected off the surface, minimizing glare and improving overall visibility.

The anti-reflective properties are achieved through various mechanisms, such as multilayer interference coatings or textured surface treatments, that alter the refractive index and optimize light transmission.

Optical Clarity and Transparency:

Anti-reflective polycarbonate sheets maintain the inherent optical clarity and transparency of standard polycarbonate materials, ensuring unobstructed visibility and light transmission.

The anti-reflective treatment does not compromise the sheet's light transmittance or visual clarity, making it an ideal choice for applications where clear visibility is essential.

Anti-reflective polycarbonate sheets offer a unique combination of optical performance, durability, and versatility, making them a valuable solution for a wide range of applications where reducing glare and enhancing visibility are critical. By combining the inherent strengths of polycarbonate with advanced anti-reflective technologies, these sheets provide a practical and effective solution for various industries and environments.

product parameters

|

Characterics |

Unit |

Data |

|

Impact strength |

J/m |

88-92 |

|

Light transmission |

% |

50 |

|

Specify Gravity |

g/m |

1.2 |

|

Elongation at break |

% |

≥130 |

|

Coefficient thermal expansion |

mm/m℃ |

0.065 |

|

Service temperature |

℃ |

-40℃~+120℃ |

|

Heat conductively |

W/m²℃ |

2.3-3.9 |

|

Flexural strength |

N/mm² |

100 |

|

Modulus of elasticity |

Mpa |

2400 |

|

Tensile strength |

N/mm² |

≥60 |

|

Soundproof index |

dB |

35 decibel decrease for 6mm solid sheet |

WHAT IS Anti-reflective polycarbonate sheets

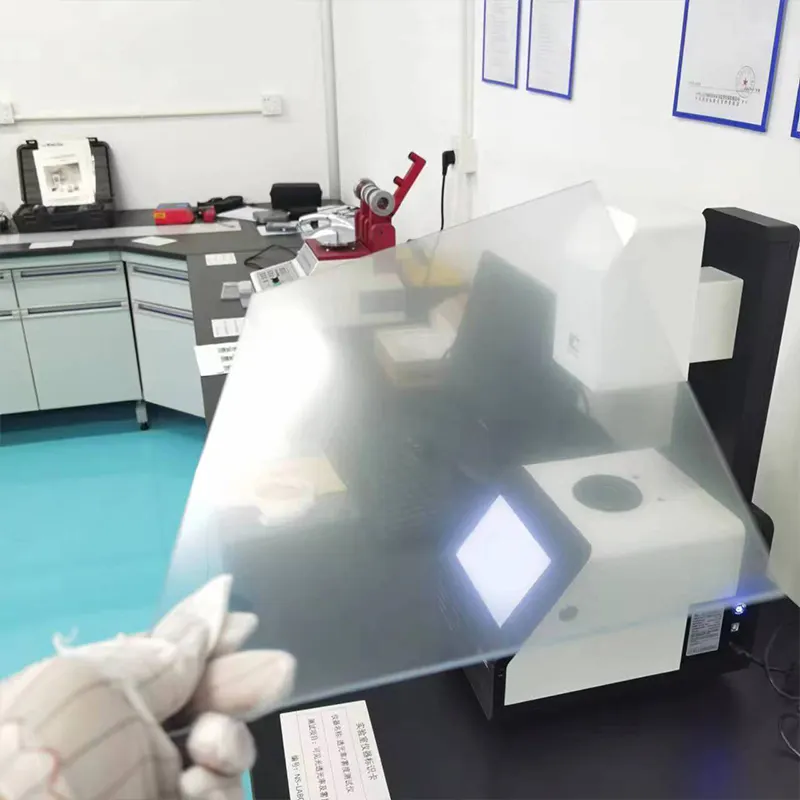

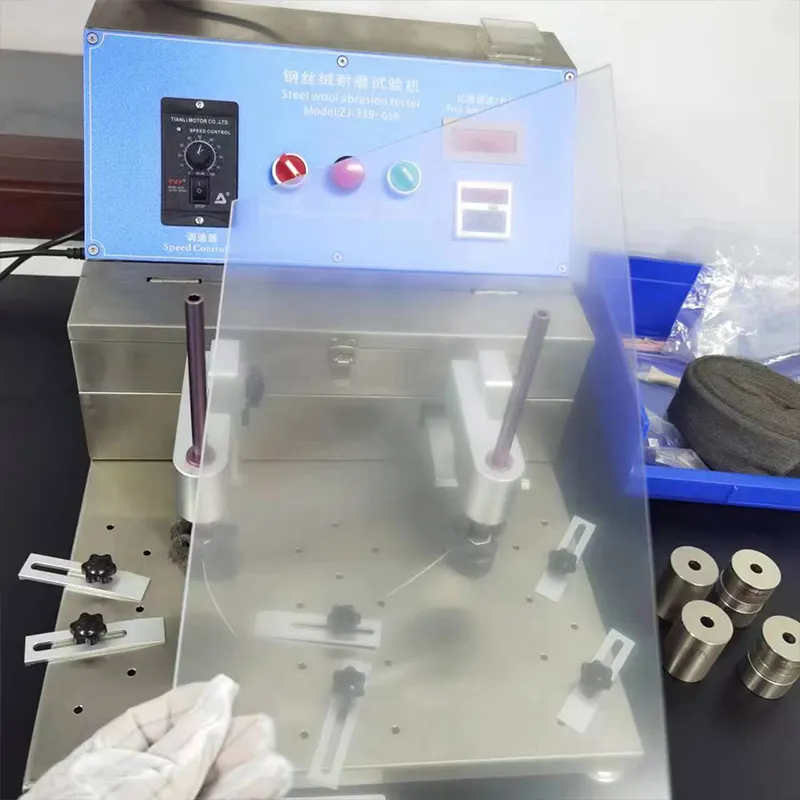

Anti-glare polycarbonate sheets and films are engineered to address the common issue of glare and reflections on polycarbonate surfaces. These products consist of two layers of polycarbonate material, separated by a UV-resistant coating. This structure not only makes the sheets resistant to scratches but also effectively mitigates glare, allowing for improved visual clarity.

The anti-glare coating on these polycarbonate products works by scattering and diffusing incoming light, rather than reflecting it directly back. This process reduces the intensity of the light that is reflected off the surface, thereby minimizing glare. As a result, the viewer experiences less eye strain and enjoys enhanced image resolution and color contrast. This makes these sheets and films ideal for a variety of applications where visual clarity and comfort are paramount.

Product advantages

Product application

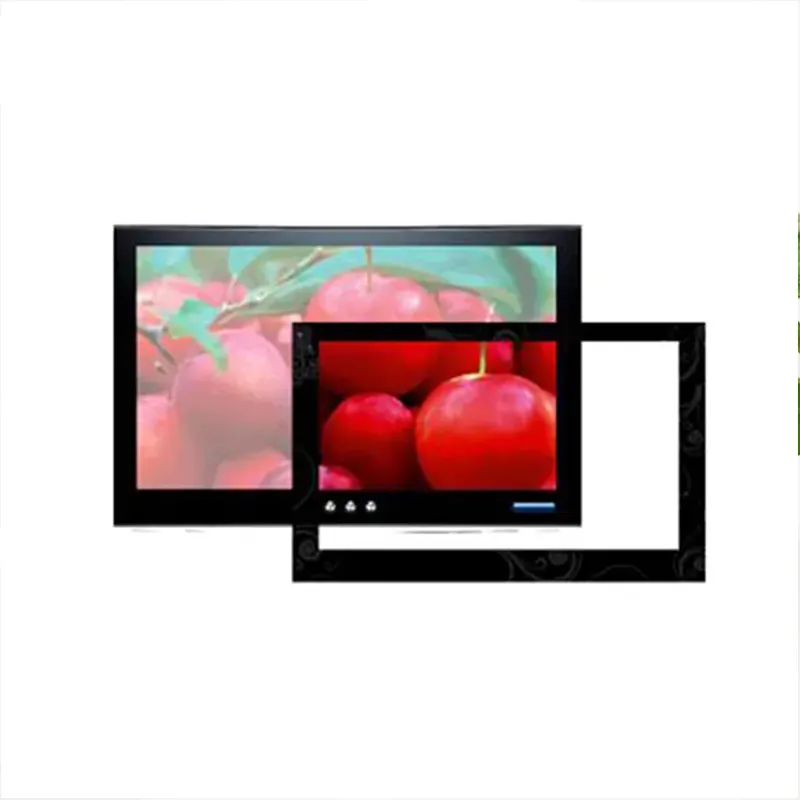

Display and Electronic Devices:

Covers and screens for laptops, tablets, and smartphones

Protective panels for digital signage, kiosks, and touch screens

Enclosures and housings for various electronic devices

Automotive and Transportation:

Windshields, side windows, and sunroofs

Instrument panel covers and display screens

Protective covers for transportation equipment

Safety and Personal Protective Equipment (PPE):

Visors, face shields, and goggles

Protective partitions and barriers

Transparent enclosures for industrial settings

Retail and Hospitality:

Showcases, display cases, and countertops

Sneeze guards and food service partitions

Shower and bathroom enclosures

Healthcare and Medical:

Observation windows and panels in medical facilities

Protective barriers and partitions in healthcare settings

Incubator and equipment covers

COLOR

Clear/Transparent:

- This is the most common and popular option, offering maximum light transmission and optical clarity

- Transparent PC sheets are widely used for glazing, skylights, and other applications where clear visibility is desired

Tinted:

- Polycarbonate sheets can be produced with various tinted or colored options

- Common tint colors include smoke gray, bronze, blue, green, and amber

- Tinted PC sheets can be used to provide glare reduction, enhanced privacy, or specific aesthetic effects

Opal/Diffused:

- Opal or diffused polycarbonate sheets have a translucent, milky appearance

- They provide a soft, even light diffusion, reducing direct glare and hot spots

- Opal PC sheets are often used for lighting fixtures, partitions, and other applications requiring diffused illumination

Versatility in Fabrication

Anti-reflective polycarbonate sheets can be easily cut, drilled, bent, and thermoformed, allowing for a wide range of customization and design possibilities.

The anti-reflective properties are typically integrated during the manufacturing process, ensuring consistent performance across the entire sheet.

Cutting:

- Cutting to Size: Polycarbonate sheets can be cut to the desired size using various methods, such as:

- Circular saws or table saws with fine-toothed blades designed for plastics

- CNC (Computer Numerical Control) routers or laser cutters for precise, custom shapes

- Manual scoring and snapping for simple straight-line cuts

- Cutting to Size: Polycarbonate sheets can be cut to the desired size using various methods, such as:

Trimming and Edging:

- Edge Finishing: The edges of the cut polycarbonate sheets can be finished using techniques like:

- Grinding or sanding to smooth the edges

- Applying edge treatments, such as decorative edge moldings or polished edges

- Edge Finishing: The edges of the cut polycarbonate sheets can be finished using techniques like:

Drilling and Punching:

- Holes and Openings: Polycarbonate sheets can be drilled or punched to create holes, slots, or other openings as required for the application.

- Specialized drill bits and punches designed for plastics are typically used to prevent cracking or chipping.

Thermoforming:

- Complex Shapes: Polycarbonate sheets can be thermoformed into various three-dimensional shapes, such as curved or contoured panels, using specialized molds and heating equipment.

- This process allows for the creation of custom-shaped parts from flat sheets.

Why choose us?

ABOUT MCLPANEL

Our advantage

FAQ

Company Advantages

Shanghai mclpanel New Materials Co., Ltd. is a professional company. We are mainly engaged in the R&D, production, and sales of Polycarbonate Solid Sheets,Polycarbanote Hollow Sheets,U-Lock Polycarbonate,plug in polycarbonate sheet,Plastic Processing,Acrylic Plexiglass Sheet. Mclpanel strives to provide professional services to meet customer demand and create great value for customers. Welcome to contact us.