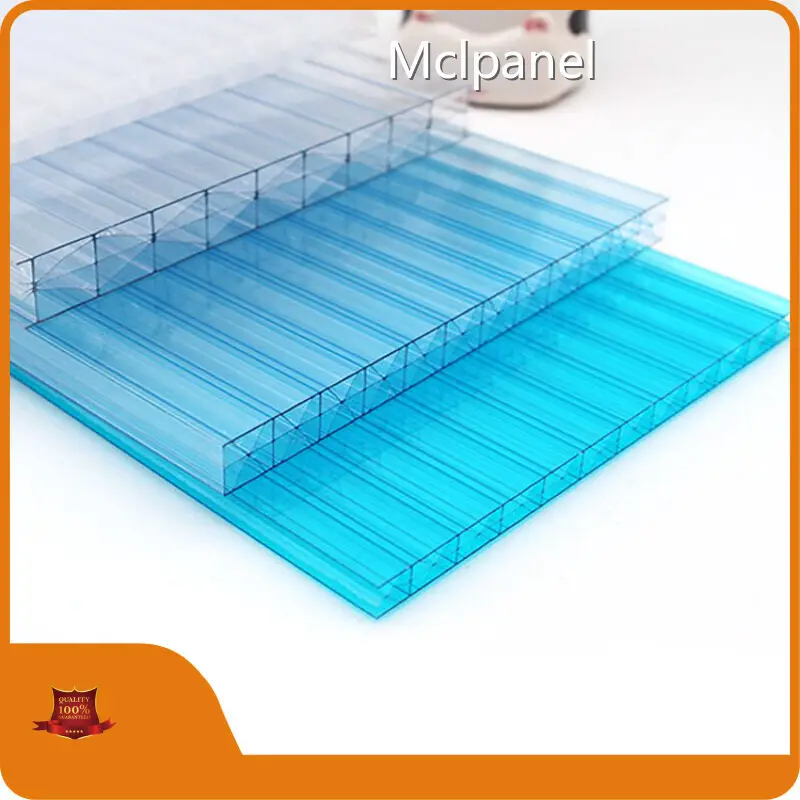

Focus on PC/PMMA sheet production and processing jason@mclsheet.com +86-187 0196 0126

Black Polycarbonate Sheet for Aquariums on Sale

Product details of the black polycarbonate sheet

Product Description

Some of Mclpanel black polycarbonate sheet has come up to advanced and world-class production standards. The product has a high cost performance for its strong functionality and high performance. Shanghai mclpanel New Materials Co., Ltd. has a knowledgeable talent team and a stable and reliable production line.

Product Description

X structure Polycarbonate Sheet are a series of multi-wall polycarbonate sheet products, they are commonly used in applications such as roofing, skylights, greenhouses, partitions, and noise barriers. They offer a combination of strength, durability, thermal insulation, light transmission, and impact resistance, making them versatile and suitable for various construction and architectural projects.

Key Characteristics of X-Structure Polycarbonate Sheets:

Structural Integrity:

The X structure or honeycomb-like internal structure of these polycarbonate sheets provides exceptional rigidity and load-bearing capacity.

The interconnected cross-members and internal cavities distribute applied forces and stresses more efficiently, enhancing the overall structural integrity of the sheet.

Lightweight Design:

The internal X-structure or honeycomb design allows for a significant reduction in the overall weight of the polycarbonate sheet, compared to solid or multi-wall polycarbonate variants.

This lightweight construction makes the sheets easier to handle, transport, and install, while still maintaining high strength and durability.

Durability and Impact Resistance:

X-structure polycarbonate sheets retain the exceptional durability, impact resistance, and weatherability of standard polycarbonate materials.

The internal structure enhances the sheet's resistance to deformation, cracking, and shattering under physical impacts or load-bearing conditions.

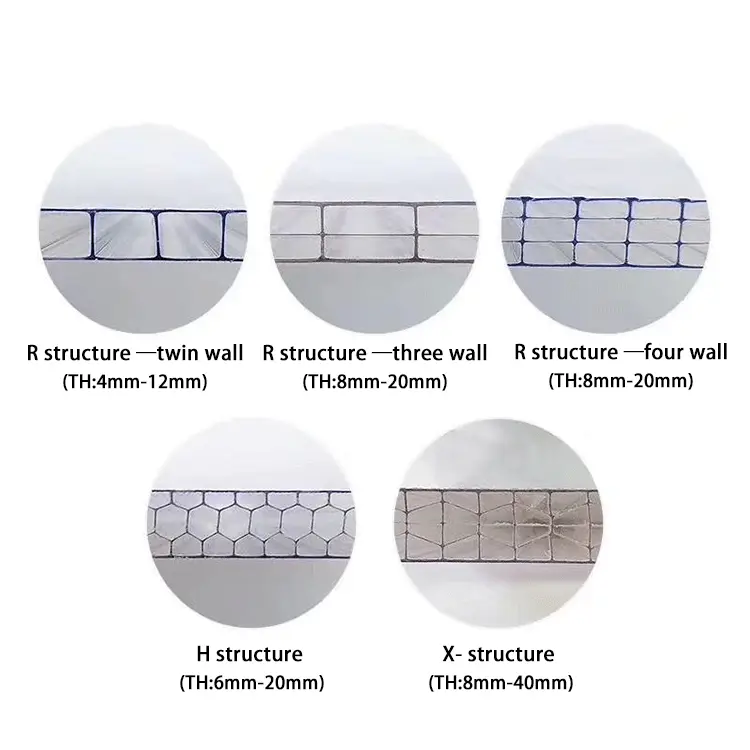

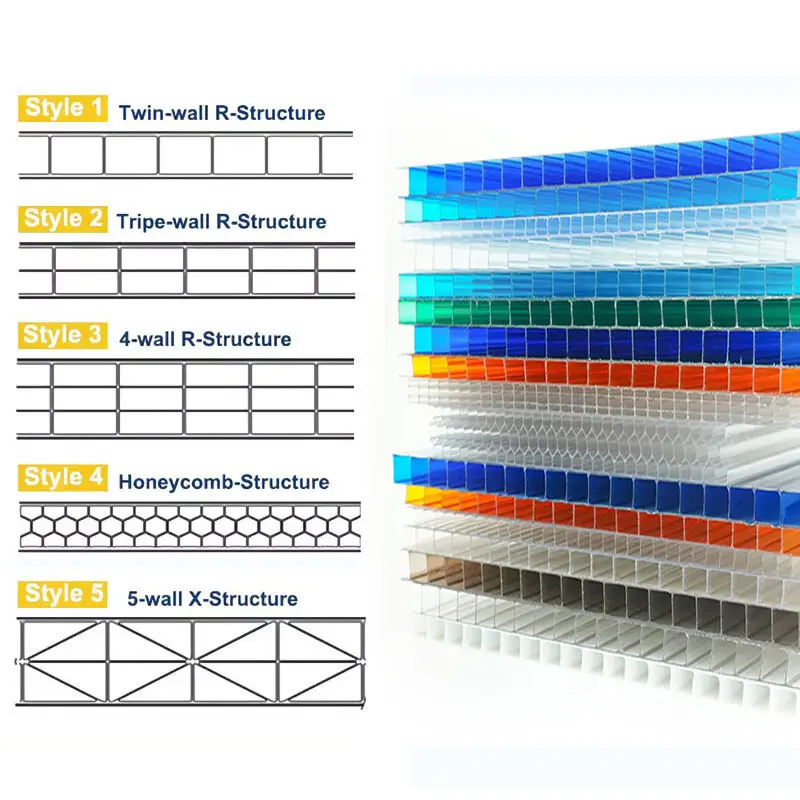

product structure

Outer Layers:

The outer layers are made of solid polycarbonate material, typically 0.5-1.5 mm thick.

These outer skins provide strength, impact resistance, and weather protection.

Internal Structures:

Between the outer layers are hollow chambers or cavities.

These internal cavities are created by adding additional polycarbonate sheets or profiles within the panel.

The chambers are usually rectangular or hexagonal in shape.

Number of Layers:

Polycarbonate hollow sheets can have 3, 5, 7, or even more internal layers/cavities.

The more layers, the higher the insulation and structural properties, but also the weight.

Wall Thickness:

The total thickness of the hollow sheet panel is typically between 4-25 mm, depending on the number of internal layers.

The walls separating the internal cavities are usually 0.5-1 mm thick polycarbonate.

product parameters

|

Product Name |

X Structure Multi-Wall Polycarbonate Sheets |

|

Place of Origin |

Shanghai |

|

Material |

100% Virgin polycartonate material |

|

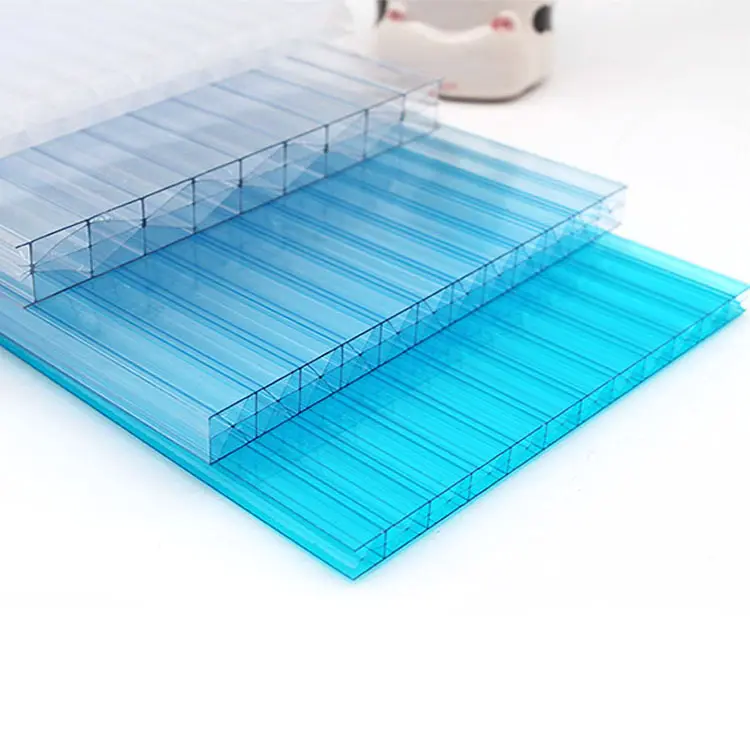

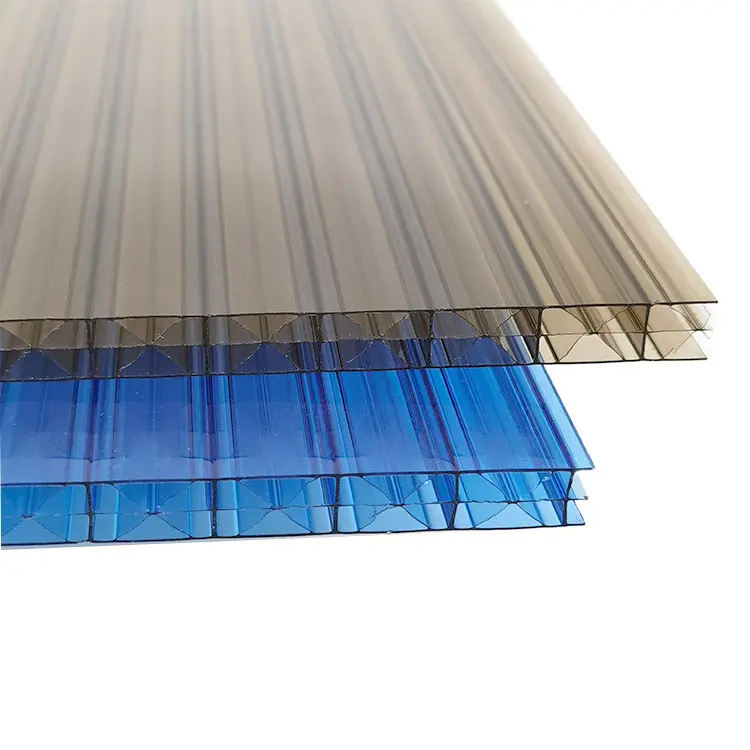

Colours |

Clear, bronze, blue, green, opal, gray or customized |

|

Thickness |

8mm-40 mm or customized |

|

Width |

2.1m , 1.22m or customized |

|

Length |

5.8m/6m/11.8m/12m or customized |

|

Surface |

With 50 micron UV protection , heat resistance |

|

Retardant standard |

Grade B1 (GB Standard) Polycarbonate hollow sheet |

|

Packaging |

Both sides with PE film, logo on the PE film. Customized package is available too. |

|

Delivery |

Within 7-10 working days once we received the deposit. |

Product application

● Applications of X Structure Multi-Wall Structure Polycarbonate Sheets:

● Roofing: X Structure multi-wall structure polycarbonate sheets are commonly used for roofing applications. Their enhanced strength, thermal insulation properties, and high light transmission make them suitable for both residential and commercial roofing projects.

● Skylights: The light transmission properties of X Structure multi-wall structure polycarbonate sheets make them ideal for skylights. They allow natural light to enter the space while providing thermal insulation and impact resistance.

● Partitions: X Structure multi-wall structure polycarbonate sheets can be used as partitions to create separate areas within a space. They provide privacy while still allowing light to pass through, creating a bright and open atmosphere.

● Greenhouses: The thermal insulation properties of X Structure multi-wall structure polycarbonate sheets make them suitable for greenhouse applications. They help to maintain optimal temperatures for plant growth while allowing sufficient light transmission.

● Protective Barriers: Due to their enhanced strength and impact resistance, X Structure multi-wall structure polycarbonate sheets can be used as protective barriers in various settings. They can be used as safety barriers, noise barriers, or as protective covers for machinery.

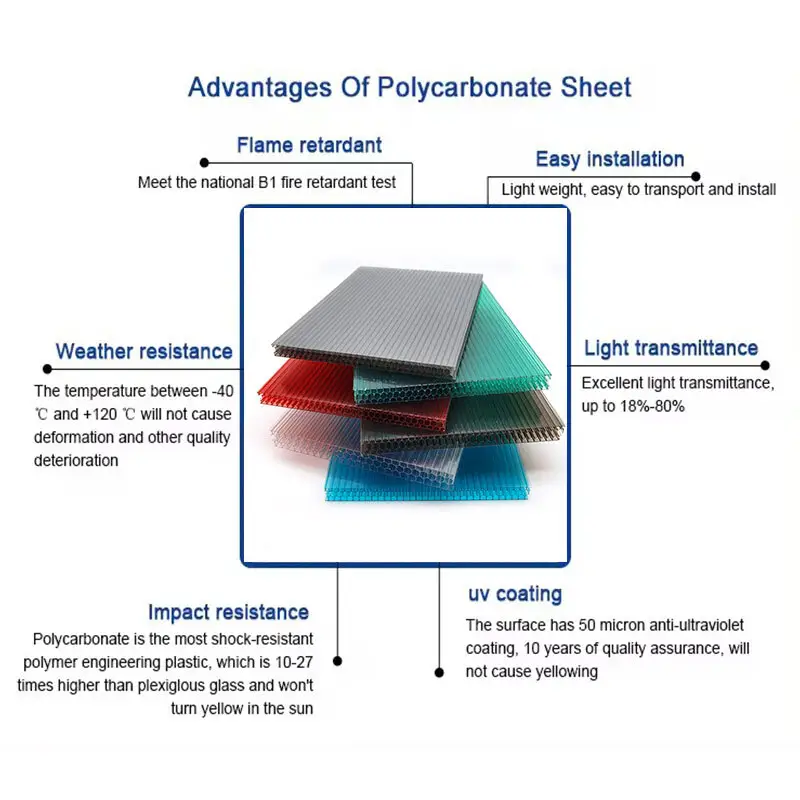

Features

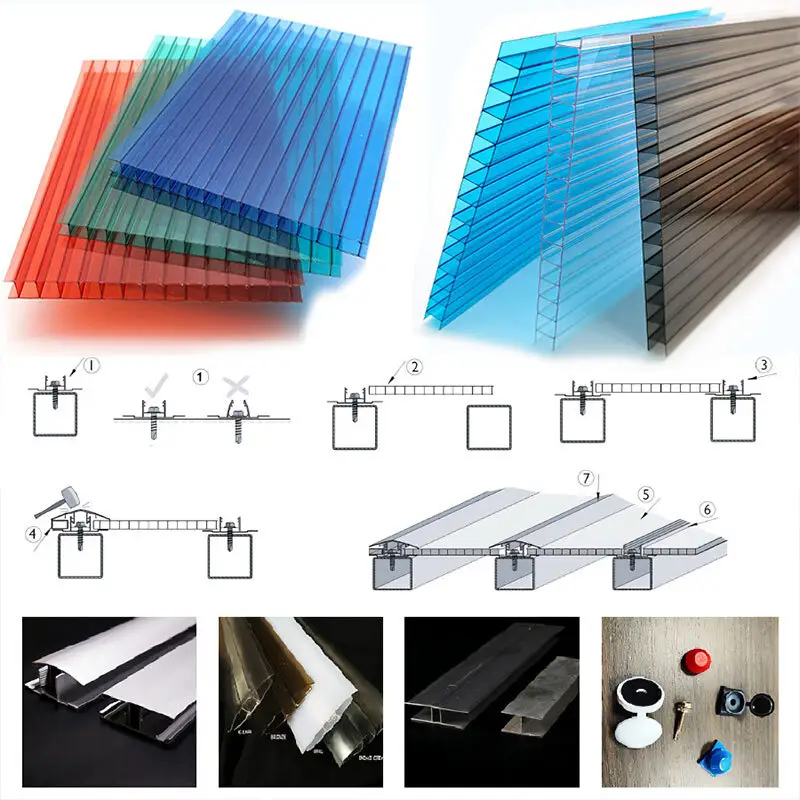

MCLpanel provides matching spare parts, intermediate connection system

● High thermal insulation

● Lighter weight than solid panels

● Excellent rigidity and impact resistance

● Available in clear and a variety of tints

● Superior structural durability

● Weather and UV resistant

● Easy to handle and install

● High fire performance rating

POLYCARBONATE SHEET VIDEO DISPLAY

iscover the benefits of choosing MCLPanel hollow polycarbonate sheets in this informative video. Learn how our lightweight, durable, and highly transparent panels provide excellent thermal insulation and UV protection. Ideal for greenhouses, skylights, and various architectural applications, MCLPanel sheets offer superior impact resistance and are easy to fabricate. Watch now to see why MCLPanel is the perfect choice for your construction needs.

POLYCARBONATE SHEETS INSTALLATION

Installing hollow polycarbonate sheet is straightforward. Start by measuring and cutting the sheets to size. Use proper support structures and secure the sheets with screws and caps. Ensure the UV-protected side faces outward.

1. Measure and prepare: Measure the area where you plan to install the polycarbonateSheet to determine the required dimensions.

2. Prepare the supporting structure: Before installing the Plastic Polycarbonate Sheet make sure the supporting structure, such as a frame or rafters, is properly prepared and structurally sound.

3. Cut the Plastic Polycarbonate Sheet : Using appropriate cutting tools, carefully cut the polycarbonate Plastic Polycarbonate Sheet to the required size and shape.

4. Pre-drill holes: Along the edges of the Plastic Polycarbonate Sheet , pre-drill holes that are slightly larger than the diameter of the screws you will be using.

5. Install the PlasticPolycarbonate Sheet : Place the first sheet in position, aligning it with the supporting structure. Insert screws through the pre-drilled holes and secure the Plastic Polycarbonate Sheet to the structure.

Why Use X structure Polycarbonate Sheets for Market Glazing Roofs?

X structure polycarbonate sheets are ideal for market glazing roofs due to their superior strength, lightweight nature, and excellent thermal insulation. The unique X structure design enhances durability and impact resistance, ensuring the roof can withstand harsh weather conditions and heavy loads.

These sheets provide high light transmission, creating a bright and welcoming environment while protecting against harmful UV rays. Their easy installation and low maintenance make them a cost-effective solution for large market areas.

Additionally, X structure polycarbonate sheets are eco-friendly and recyclable, aligning with sustainable building practices. Choose X structure polycarbonate sheets for a reliable, efficient, and environmentally conscious roofing solution.

Does X structure Polycarbonate Sheets is Suitable for partition decoration?

X structure polycarbonate sheets are highly suitable for partition decoration. Their unique X structure design offers enhanced strength and rigidity while maintaining a lightweight profile, making them easy to handle and install. These sheets provide excellent light transmission, allowing natural light to permeate spaces while maintaining privacy, which is ideal for creating bright and airy interiors. The polycarbonate material is also highly durable and impact-resistant, ensuring long-lasting partitions that can withstand daily wear and tear.

Moreover, these sheets are easy to clean and require minimal maintenance, making them a practical choice for both residential and commercial spaces. Their insulating properties help in regulating temperature, contributing to energy efficiency.

In addition to their functional benefits, X structure polycarbonate sheets come in various colors and finishes, offering versatile aesthetic options to complement different interior design styles. Their UV resistance ensures that the sheets do not yellow or degrade over time, maintaining their appearance and performance.

Our Advantages

Tailor-Made Multiwall Polycarbonate Sheet for Your Projects

ABOUT MCLPANEL

Our advantage

FAQ

Company Advantage

• Mclpanel has vigorously explored the domestic and overseas markets in various ways. Polycarbonate Solid Sheets,Polycarbanote Hollow Sheets,U-Lock Polycarbonate,plug in polycarbonate sheet,Plastic Processing,Acrylic Plexiglass Sheet are currently sold well in some countries and regions in Europe, America, and Australia.

• Mclpanel's location has unique geographical advantages, complete supporting facilities, and traffic convenience.

• Established in Mclpanel has become a famous enterprise in the industry after years' development.

• Our company has received a group of high-quality and high-efficiency talents. They have rich industry experience and exquisite production technology. As an important human resource for our company, our talents provide strong support for the efficient operation.

Mclpanel's tools are provided with fine workmanship and reliable quality. Feel free to consult us and we invite people from all walks of life to visit our factory. And we are willing to pay for your traffic fee.