Focus on PC/PMMA sheet production and processing jason@mclsheet.com +86-187 0196 0126

Cost of Polycarbonate Sheets Mclpanelaluminum Foil

Product Description

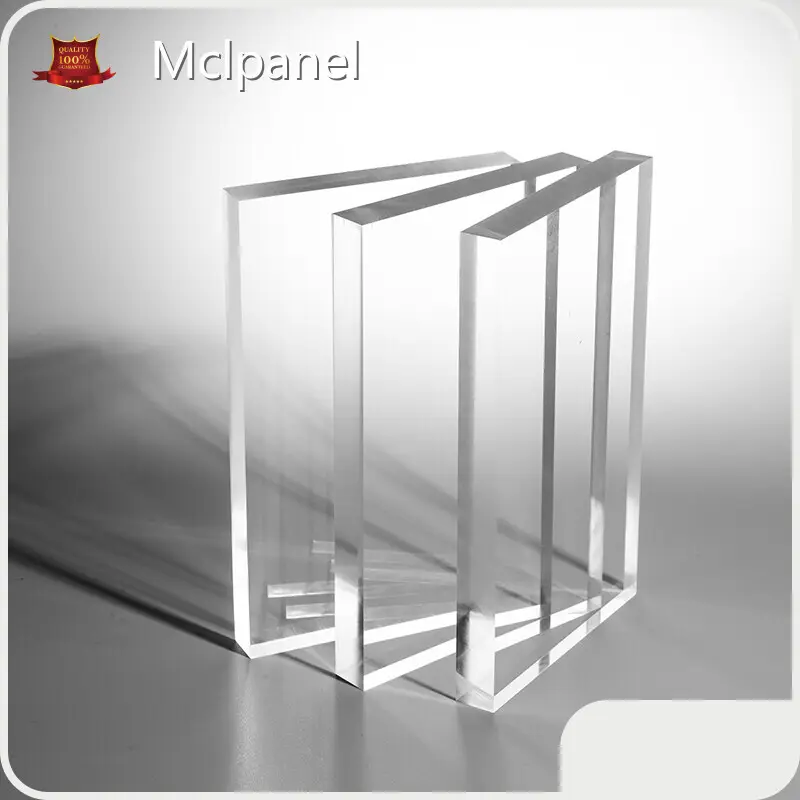

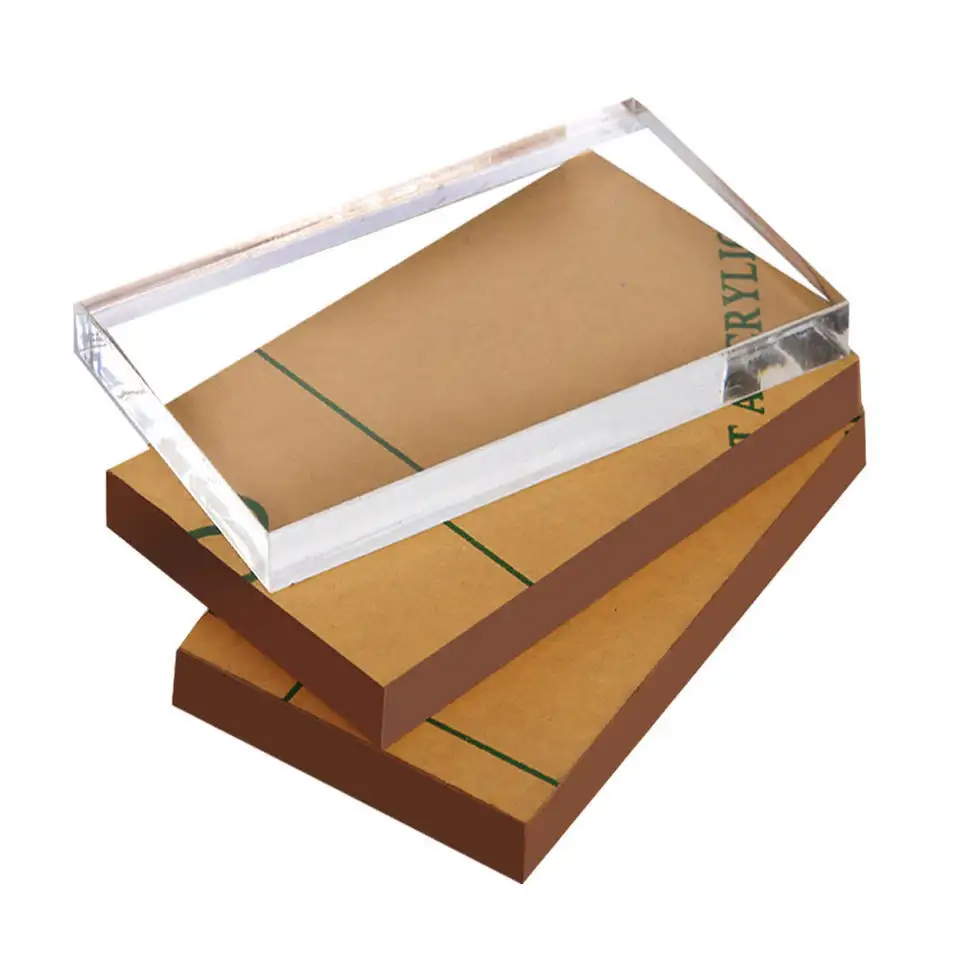

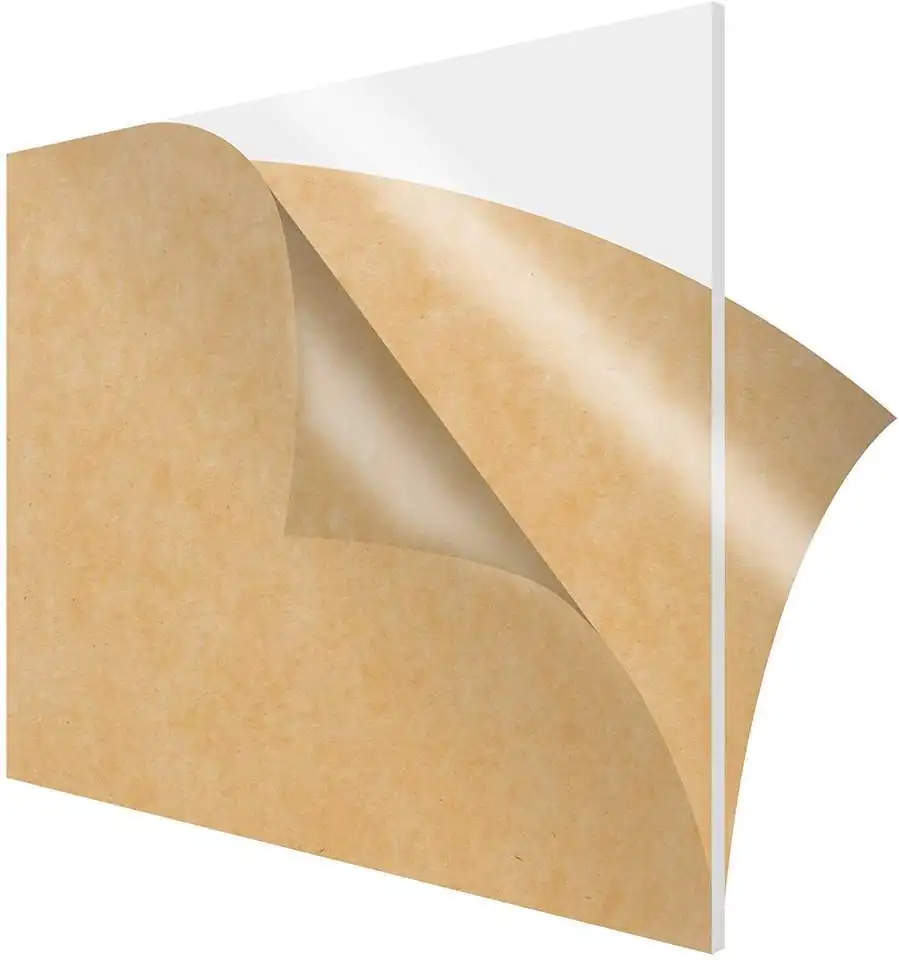

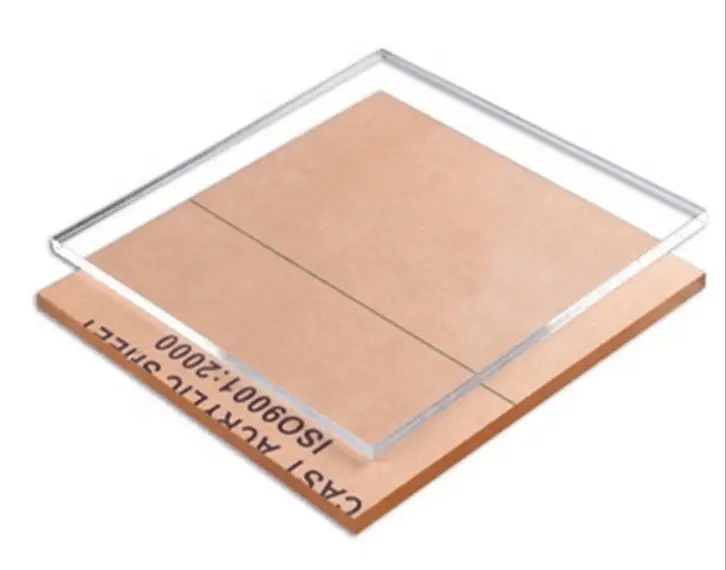

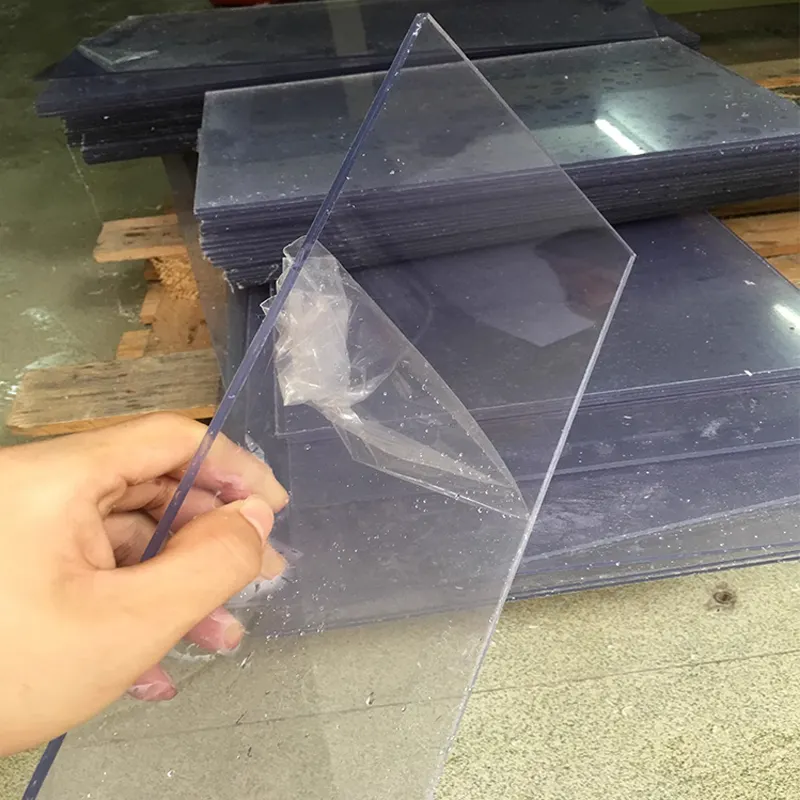

Clear acrylic plastic sheets, also known as plexiglass or polymethyl methacrylate (PMMA), are a popular choice for a wide range of applications due to their exceptional optical clarity, durability, and design flexibility. These transparent sheets offer numerous benefits that make them a valuable material in the construction, design, and manufacturing industries.

Key Characteristics of Clear Acrylic plastic sheets:

Optical Clarity:

Clear acrylic sheets provide exceptional clarity and transparency, allowing for unobstructed visibility and light transmission.

They exhibit a high refractive index, which results in a glass-like appearance and can enhance the aesthetic appeal of a space.

Lightweight and Impact-Resistant:

Acrylic sheets are significantly lighter than glass, typically about half the weight of an equivalent glass panel.

Despite their lightweight nature, they possess excellent impact resistance, making them a safer option in high-traffic areas or applications where safety is a concern.

Weather and UV Resistance:

Clear acrylic sheets are highly resistant to weathering, UV radiation, and other environmental factors, ensuring long-lasting performance and minimal discoloration over time.

This durability makes them suitable for both indoor and outdoor applications, including exposure to sunlight.

Versatility in Fabrication and Finishing:

Acrylic sheets can be easily cut, drilled, bent, and thermoformed, allowing for a wide range of customization and fabrication possibilities.

They can be polished, etched, or decorated with various techniques to achieve desired aesthetic effects.

Easy Maintenance and Cleaning:

Clear acrylic sheets require minimal maintenance compared to glass, as they are less prone to scratches and can be easily cleaned with mild detergents or specialized acrylic cleaners.

This low-maintenance feature makes them suitable for high-traffic areas and applications where cleanliness is important.

product parameters

|

Material |

100% virgin material |

|

Thickness |

1.8, 2, 3, 4, 5, 8,10,15,20, 30, 50,60mm (1.8-60mm) |

|

Color |

Transparent, white, opal, black, red, green, blue, yellow, etc. OEM color OK |

|

Standard size |

1220*1830, 1220*2440, 1270*2490, 1610*2550, 1440*2940, 1850*2450, 1050*2050, 1350*2000, 2050*3050, 1220*3050 mm |

|

Certificate |

CE, SGS, DE, and ISO 9001 |

|

Equipment |

Imported glass models (from Pilkington Glass in U. K.) |

|

MOQ |

2 tons, can be mixed with colors/ sizes/ thickness |

|

Delivery |

10-25 days |

Advantages

PRODUCT Advantages

Product application

● Windows and Glazing: Acrylic sheets are used for windows in commercial buildings, residential homes, and vehicles.

● Signage and Displays: Acrylic sheets are commonly used in signage applications, including indoor and outdoor signs, illuminated signs, point-of-sale displays, and trade show exhibits.

● Protective Barriers and Shields: Acrylic sheets are used to create protective barriers and shields in various settings.

● Lighting Fixtures: Acrylic sheets are utilized in lighting applications, such as diffusers and light covers, to distribute and diffuse light evenly.

● Aquariums and Display Cases: Acrylic sheets are often used in the construction of aquariums, fish tanks, and display cases.

● Furniture and Home Decor: Acrylic sheets are used to create furniture pieces, such as chairs, tables, and shelves.

● Medical and Healthcare Equipment: Acrylic sheets are employed in the healthcare industry for applications such as isolation chambers, medical equipment components, protective barriers in laboratories, and medical device enclosures.

● Roofing and Skylights: Acrylic sheets are used as roofing materials and in skylights to allow natural light into buildings.

● Art and Craft Projects: Acrylic sheets are popular among artists and crafters for various projects.

● Greenhouses: Acrylic sheets are used in greenhouse construction to create a controlled environment for plant growth.

color

Acrylic sheets are available in a wide variety of colors, allowing for flexible design options. Here's an overview of the main acrylic color choices:

Clear/Transparent:

This is the most common and popular acrylic color option. Clear acrylic offers excellent optical clarity.

Tinted/Colored:

Acrylic can be pigmented during manufacturing to create a wide range of solid colors, including:

Red

Blue

Green

Yellow

Black

White

And many other hues

Translucent:

Translucent acrylic sheets allow some light to pass through while providing a diffused, frosted appearance.

These can create interesting lighting effects and decorative looks.

COMMON PROCESSING

Acrylic/polycarbonate is a versatile material that can be processed using a variety of common manufacturing techniques. Here are some of the most common acrylic fabrication and processing methods:

Cutting and Shaping:

Laser Cutting: Precise and clean cuts can be achieved using computer-controlled laser cutting machines.

CNC Machining: Computer Numerical Control (CNC) milling and routing machines can be used to cut complex shapes and profiles in Acrylic/polycarbonate.

Bonding and Joining:

Adhesive Bonding: Acrylic/polycarbonate can be joined using various adhesives, such as cyanoacrylate (super glue), epoxy, or acrylic-based cements.

Solvent Bonding: Solvents like methylene chloride or acrylic-based cements can be used to chemically weld acrylic parts together.

Bending and Forming:

Thermoforming: Acrylic/polycarbonate sheets can be heated and formed into various shapes using molds or bending jigs.

Cold Bending: Acrylic/polycarbonate can be bent and shaped at room temperature, particularly for simple curves and angles.

Flame Bending: Carefully applying a flame to the Acrylic/polycarbonate surface can soften the material, allowing it to be bent and shaped.

Printing and Decoration:

Screen Printing: Acrylic/polycarbonate sheets can be screen printed with various inks and graphics to add visual interest or branding.

Digital Printing: Wide-format digital printers can be used to directly print images, text, or graphics directly onto acrylic surfaces.

WHY CHOOSE US?

ABOUT MCLPANEL

Our advantage

FAQ

Company Advantages

· Mclpanel cost of polycarbonate sheets is China-made with purity, craft and timeless appeal in mind.

· Through the whole process of strict quality inspection, we ensure product quality to meet industry standards.

· Shanghai mclpanel New Materials Co., Ltd.'s years of development and exploration have developed various cost of polycarbonate sheets of different types.

Company Features

· For years, Shanghai mclpanel New Materials Co., Ltd. has been specializing in the design, production, and trade of cost of polycarbonate sheets. We have accumulated rich experience in our business.

· We have teams of professional R&D and well-trained customer service staff. They are able to provide custom-made products including cost of polycarbonate sheets or professional advice to our customers.

· Mclpanel strives to be top in the cost of polycarbonate sheets industry. Get price!

Application of the Product

The cost of polycarbonate sheets produced by our company is widely recognized by customers and widely used in field.

We have been engaged in the production and management of Polycarbonate Solid Sheets,Polycarbanote Hollow Sheets,U-Lock Polycarbonate,plug in polycarbonate sheet,Plastic Processing,Acrylic Plexiglass Sheet for many years. For some problems encountered by customers in the procurement, we have the ability to provide customers with a practical and effective solution to help customers solve problems better.