Polycarbonate facade system

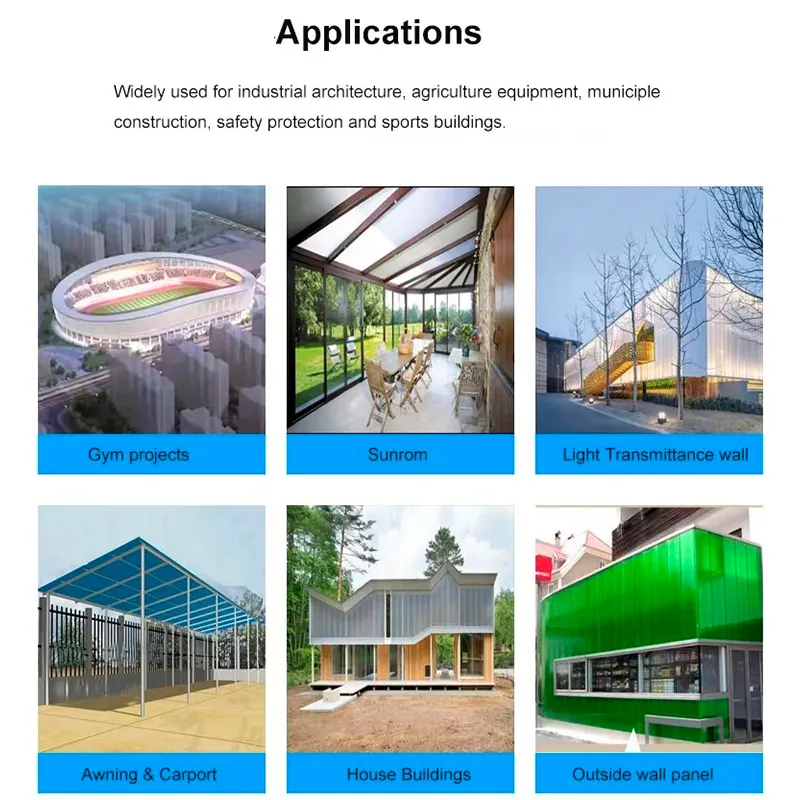

Polycarbonate wall panel facade system find applications in various industries, such as architecture, construction, transportation, signage, and interior design. They are often used for partitions, skylights, lighting fixtures, protective barriers, decorative elements, and other applications where a combination of strength, transparency, and visual aesthetics is desired.

The plug-pattern design and enhanced strength of 7 wall Rectangle structure Sheets make them suitable for facade applications. They can be used to create visually appealing and durable exterior surfaces for buildings.

ClickLoc 7 Walls Plug-Pattern Polycarbonate Sheet can be used as partitions to divide interior spaces. They provide privacy while still allowing light to pass through, creating a bright and open atmosphere.

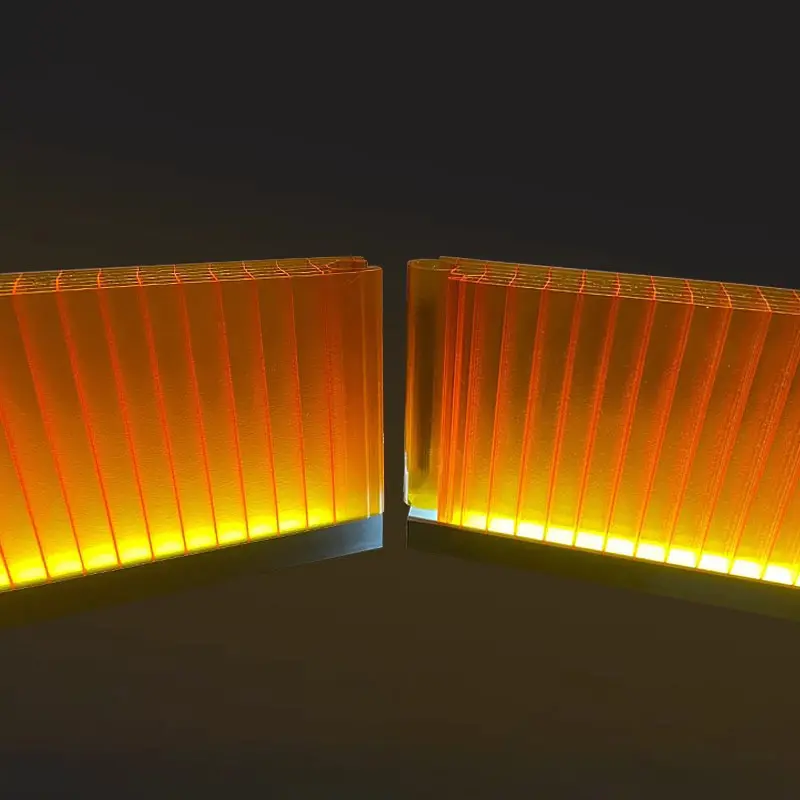

Polycarbonate hollow panels have good light transmittance, and can be used as the backlight source for advertising boards. By installing internal LED lights, they can create a uniform and soft lighting effect.

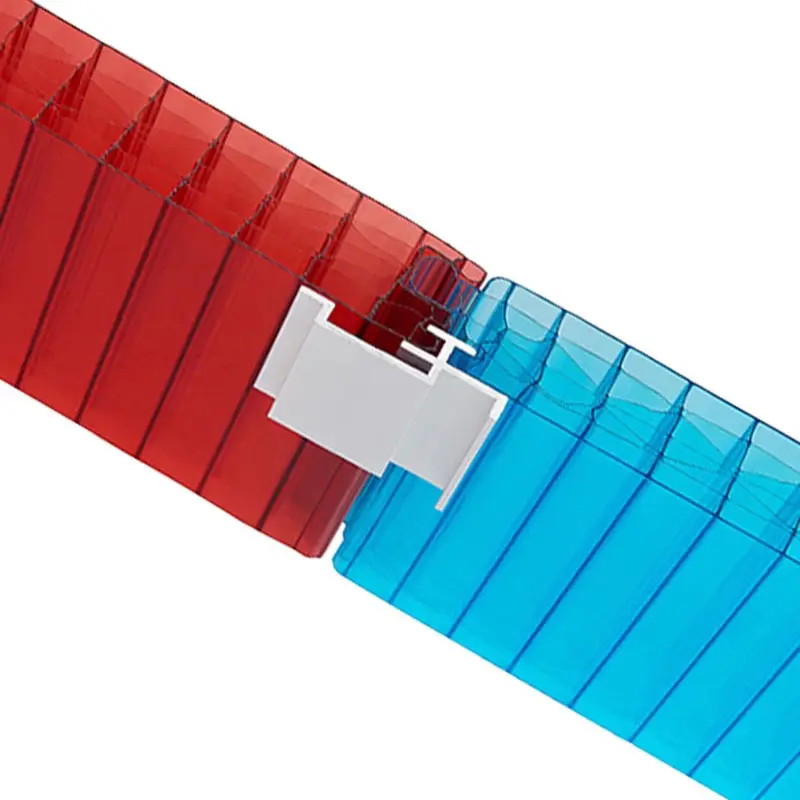

Plug-Pattern Design: The plug-pattern design of these sheets consists of small plugs or protrusions on the surface, which helps to enhance the structural integrity and stability of the sheet.

Seven-Wall Rectangle Structure: The seven-wall Rectangle structure of these sheets provides increased strength and rigidity compared to standard multi-wall polycarbonate sheets. This makes them more resistant to impacts and bending .

Seamless Glazing Option: Some 7 Walls Plug-Pattern Sheets are produced with a thermoclick system on the side edges, allowing for a seamless glazing option. This makes the installation process easier and provides a visually appealing finish.

ClickLoc Plug-Pattern Polycarbonate Sheet have emerged as a popular choice for building exteriors and facades due to their exceptional performance and design versatility. These panels offer a range of benefits that make them an attractive option for architects, contractors, and building owners.

|

Item

|

Thickness

|

Width

|

Length

|

|

Polycarbonate Plug-Pattern Panel

|

30/40 mm

|

500 mm

|

5800 mm 11800 mm Customized

|

|

Raw Material

|

100% virgin Bayer/ Sabic

|

|

Density

|

1.2 g/cm³

|

|

Profiles

|

7-Wall Rectangle/ Diamond Structure

|

|

Colors

|

Transparent, Opal, Green, Blue, Red, Bronze and Customized

|

|

Warranty

|

10 years

|

Key Characteristics and Advantages of Polycarbonate Facade Panels

Polycarbonate sheets are significantly lighter than traditional glass or metal facade materials, reducing the load on the building structure. They exhibit high impact resistance and can withstand harsh weather conditions, making them a resilient choice for exterior applications.

Polycarbonate sheets have excellent thermal insulation properties, helping to improve the energy efficiency of buildings. The multi-walled or cellular structure of these panels provides effective thermal barrier, reducing heat transfer and potentially lowering heating and cooling costs.

Polycarbonate sheets can be manufactured with varying degrees of translucency, allowing for the controlled entry of natural daylight into the building interior. This can contribute to energy savings by reducing the need for artificial lighting and enhancing the overall visual experience for building occupants.

Polycarbonate sheets come in a wide range of colors, thicknesses, and profiles, allowing architects and designers to create unique and visually appealing facade designs.

Four wall rectangular structure, seven wall rectangular structure, seven wall x structure, ten wall structure.

Plug-Pattern Design: The plug-pattern design of these sheets consists of small plugs or protrusions on the surface, which helps to enhance the structural integrity and stability of the sheet.

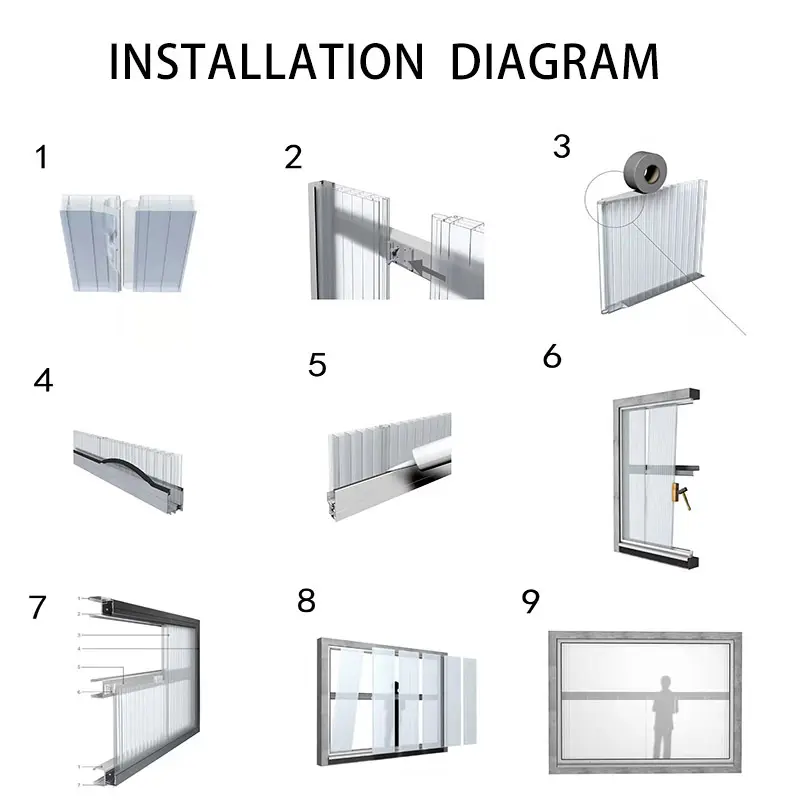

For minimizing the infltration of dust particles into the chambers of the panels, the panel ends have to be sealed carefulyThe upper panel end and lower end must be tightly sealed with Anti-Dust-Tape. lt is important that tongue and groove jointof the panels are also sealed completely and carefully.

1.The protective film of the panels must be removed in areas of taping. lt must be ensured that remove the protective filmfrom all around about 6cm when the panels are set into the frame profile.

2.There must be an expansion joint of approx. 3-5mm in between(this value is valid for an installation temperature of +20 degree)

3.The fastener must be positioned at the horizontal bar and must be pushed against the panel. The fastener must be fixedwith at least two screws at the crossbar.

4.Depending on panel length,it is necessary to use hammer and softwood to interlock the panels.

5.Take care that the fastenersare positioned exactly inside the notches of the panels.

6.The gasket must be pressed directly tightly onto the front panel so it is put under tension and fixed.Chemical resistance of polvcarbonate against other chemicals used are to be checked by customer on site.

Colors & Logo can be customized.

BSCI & ISO9001 & ISO, RoHS.

Competitive price with high quality.

10 years of quality assurance

Inspire Creative Architecture with MCLpanel

MCLpanel is professional in polycarbonate production, cut, package and installation. Our team always helps you find the best solution.

Shanghai MCLpanel New Materials Co., Ltd. is a comprehensive enterprise focusing on the PC industry for nearly 15 years, engaged in the research and development, production, sales, processing and service of polycarbonate polymer materials.

We have a high-precision PC sheet extrusion production line, and at the same time introduce UV co-extrusion equipment imported from Germany, and we use Taiwan's production technology to strictly control the production process to ensure product quality. At present, the company has Established long-term and stable cooperative relations with famous brand raw material manufacturers such as Bayer, SABIC and Mitsubishi.

Our product range covers PC sheet production and PC processing. PC sheet includes PC hollow sheet, PC solid sheet, PC Frosted sheet, PC Embossed sheet, PC diffusion board, PC flame retardant sheet, PC hardened sheet, U lock PC sheet, plug-in pc sheet, etc.

Our factory boasts cutting-edge processing equipment for polycarbonate sheet production, ensuring precision, efficiency, and high-quality results.

Our polycarbonate sheet manufacturing facility sources high-quality raw materials from trusted international suppliers. The imported materials ensure the production of premium polycarbonate sheets with excellent clarity, durability, and performance.

Our polycarbonate sheet manufacturing facility ensures smooth and reliable transportation of finished products. We work with trusted logistics partners to handle the efficient and secure delivery of our polycarbonate sheets. From packaging to tracking, we prioritize the safe and timely arrival of our high-quality products to our customers worldwide.

Your vision drives our innovation. If you need something beyond our standard catalogue, we’re ready to turn your ideas into reality. Our team ensures that your specific design requirements are met with precision.

1

How long is the warranty period for polycarbonate sheets? ?

A: We can provide 10 year warranty. Polycarbonate sheets are extremely impact-resistant. Thanks to their temperature and weather resistance, they have a much longer service life.

2

What are the payment terms?

A: Wire transfer advance payment (30% deposit+70% balance before shipment), letter of credit, cash.

3

What will happen in the event of a fire?

A: Fire safety is one of polycarbonate's strong points. Polycarbonate sheeting is flame retardant so they are often incorporated in public buildings.

4

Are polycarbonate sheets bad for the environment?

A: Using a very recyclable and sustainable material and 20% renewable energy, polycarbonate sheets do not emit toxic substances during combustion.

5

Can I install polycarbonate sheets myself?

A: Yes. Polycarbonate sheets are particularly user-friendly and very light, be sure to protect the construction of the organizers of the film print to understandclearly explained to the operator, with particular attention to the criteria which faces outward. Must not be installed wrong.

6

How about your package?

A: Both sides with PE films, logo can be customized Kraft paper and pallet and other requirements are available.

Company Advantages

· Assembly quality of polycarbonate sheet bunnings has been highly improved.

· The product performance is reliable, durable, welcomed by users.

· The product has been regarded as the promising one in the international market.

Company Features

· With core competitiveness of technology and quality, Shanghai mclpanel New Materials Co., Ltd. plays a leading role in the field of polycarbonate sheet bunnings.

· Shanghai mclpanel New Materials Co., Ltd. continuously enhances the company's core competitiveness.

· Sustainable practices are embedded into our value chain. We are committed to managing our economic, environmental and social impacts throughout our value chain.

Application of the Product

The polycarbonate sheet bunnings produced by Mclpanel is very popular in the market and is widely used in industry.

We strive to provide customers with efficient, complete, and flexible solutions based on their needs.