At our manufacturing facility, we offer a diverse range of transparent polycarbonate (PC) sheet products, including options with thicknesses of 2mm - 20mm. These PC panels are engineered to provide exceptional optical clarity and light transmission, making them well-suited for a wide variety of applications.

Key Characteristics of Solid Polycarbonate Sheets:

Impact Resistance:

Polycarbonate sheets are renowned for their outstanding impact resistance, far exceeding the capabilities of glass and many other plastic materials.

This makes them an ideal choice for applications where safety and protection against breakage are crucial, such as in skylights, windows, and security barriers.

Optical Clarity:

Solid polycarbonate sheets provide excellent optical clarity, with a clarity level comparable to that of glass.

They offer a transparent or translucent appearance, allowing for the transmission of light while maintaining a high degree of visibility.

Lightweight and Durable:

Polycarbonate sheets are significantly lighter in weight than glass, making them easier to handle and install.

Despite their lightweight nature, they possess remarkable durability and resistance to weathering, UV exposure, and temperature extremes.

Solid polycarbonate sheets offer a versatile and durable solution for a wide range of applications, from architectural elements to industrial and commercial settings. Their combination of impact resistance, optical clarity, and design flexibility make them a valuable choice for designers, architects, and manufacturers seeking a high-performance building material.

Regardless of the thickness, our transparent PC sheets are manufactured to the highest standards, leveraging advanced production techniques to deliver materials with consistent quality and optical properties. Customers across diverse industries rely on these thin-profile polycarbonate solutions to elevate their designs and enhance the visual experience for end-users.

|

Characterics

|

Unit

|

Data

|

|

Impact strength

|

J/m

|

88-92

|

|

Light transmission

|

%

|

50

|

|

Specify Gravity

|

g/m

|

1.2

|

|

Elongation at break

|

%

|

≥130

|

|

Coefficient thermal expansion

|

mm/m℃

|

0.065

|

|

Service temperature

|

℃

|

-40℃~+120℃

|

|

Heat conductively

|

W/m²℃

|

2.3-3.9

|

|

Flexural strength

|

N/mm²

|

100

|

|

Modulus of elasticity

|

Mpa

|

2400

|

|

Tensile strength

|

N/mm²

|

≥60

|

|

Soundproof index

|

dB

|

35 decibel decrease for 6mm solid sheet

|

Polycarbonate solid sheets are highly impact-resistant, making them extremely durable and shatter-resistant, They can withstand high impact loads without breaking or shattering, providing enhanced safety and security, This property makes them suitable for applications where impact resistance is crucial, such as in safety barriers, security glazing, and protective coverings.

Polycarbonate solid sheets offer excellent optical clarity, comparable to glass, They allow for high light transmission, providing a clear and transparent view, This optical clarity is maintained even after prolonged exposure to weathering, UV radiation, or other environmental factors.

Polycarbonate solid sheets are significantly lighter than traditional materials like glass or acrylic, The lightweight nature of PC sheets makes them easier to handle, transport, and install, This reduced weight can lead to lower installation costs and simplified structural requirements.

Polycarbonate solid sheets have good thermal insulation properties They can help reduce heat transfer, contributing to improved energy efficiency in building and construction applications, This feature can lead to lower energy consumption and operating costs for heating and cooling.

Polycarbonate solid sheets are inherently resistant to ultraviolet (UV) light, They can protect against harmful UV radiation, preventing the degradation of underlying materials and structures, This makes them suitable for outdoor applications, such as canopies, skylights, and façade systems, where UV exposure is a concern.

Polycarbonate solid sheets can be easily fabricated, bent, and thermoformed into various shapes and sizes, This allows for a high degree of design flexibility, enabling customized solutions for a wide range of applications, Architects and designers can leverage the material's versatility to create unique and innovative structures

● Unusual Decorations, Corridors And Pavilions In Gardens And Recreational And Rest Places

● Interior And Exterior Decorations Of Commercial Buildings, And Curtain Walls Of The Modern Urbanbuildings

● The Transparent Containers, Front Wind Shields Of Motorcycles, Airplanes, Trains, Ships, Vehicles. Motor Boats, Sub Marines

● Telephone Booths, Street Name Plates And Sign Boards

● Instrument And War Industries - Windscreens, Army Shields

● Walls, Roofs, Windows, Screens And Other High Quality Indoor Decoration Materials

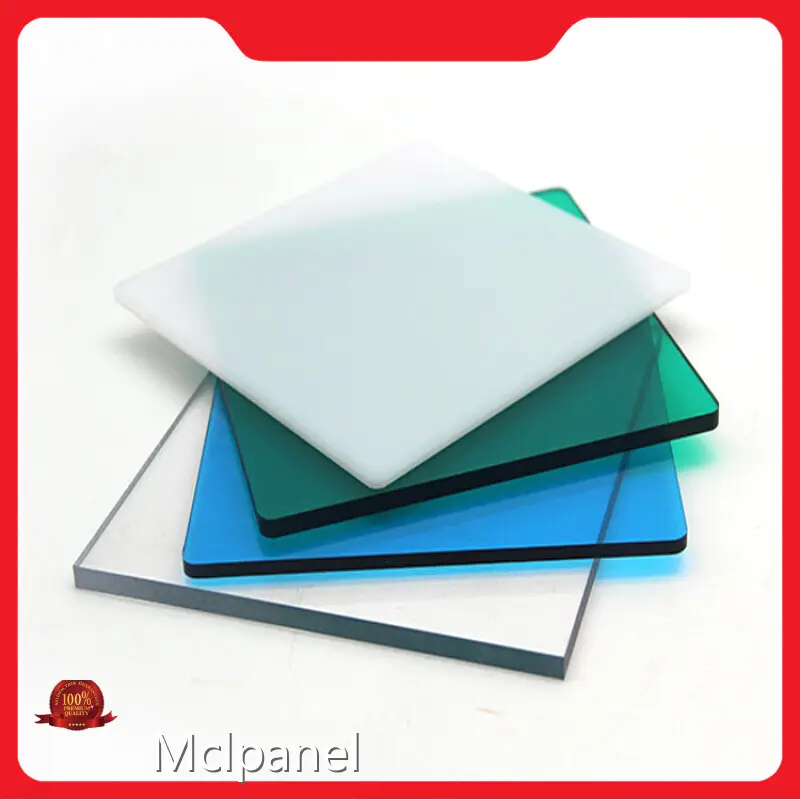

Clear/Transparent:

- This is the most common and popular option, offering maximum light transmission and optical clarity

- Transparent PC sheets are widely used for glazing, skylights, and other applications where clear visibility is desired

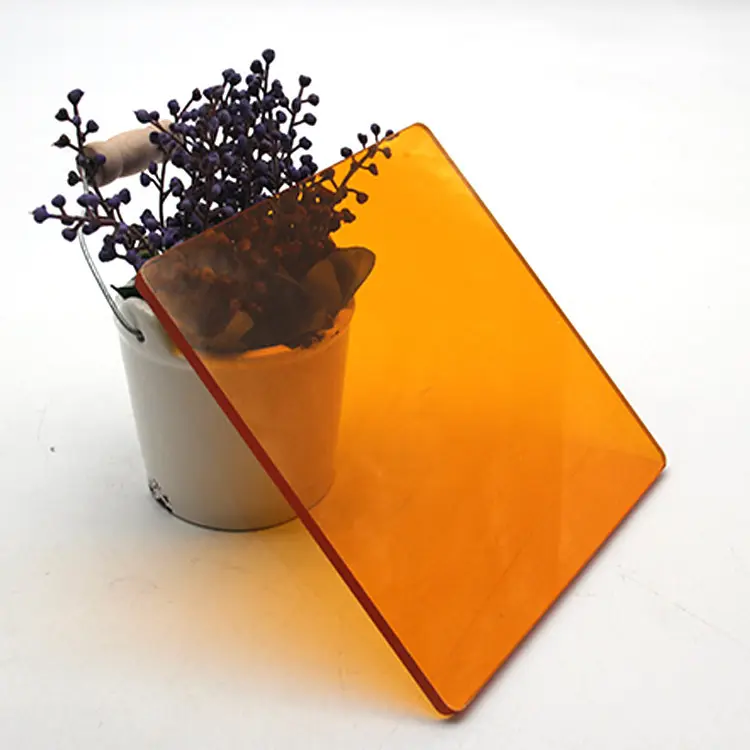

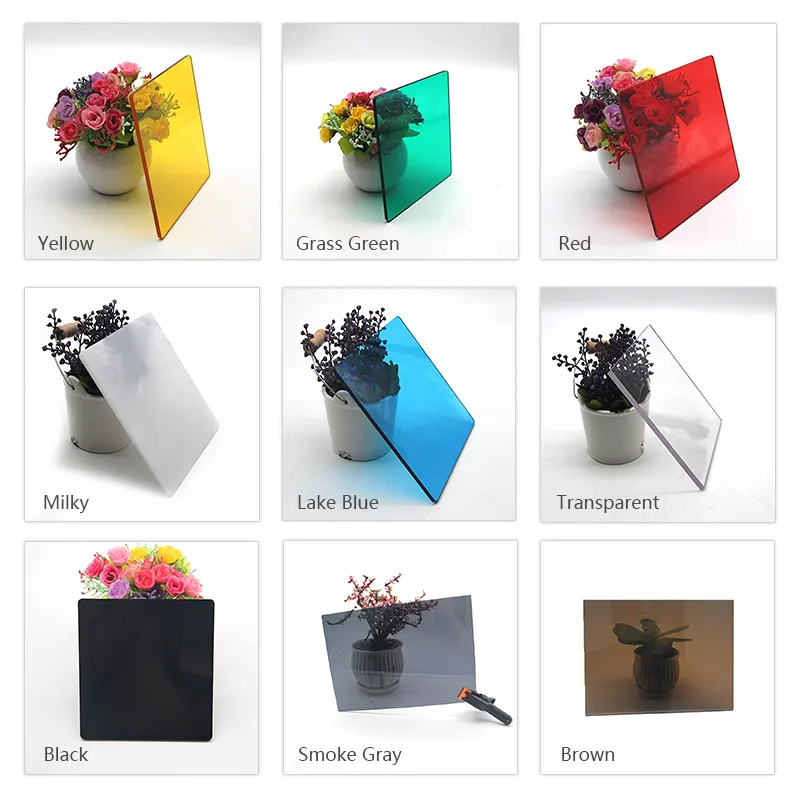

Tinted:

- Polycarbonate sheets can be produced with various tinted or colored options

- Common tint colors include smoke gray, bronze, blue, green, and amber

- Tinted PC sheets can be used to provide glare reduction, enhanced privacy, or specific aesthetic effects

Opal/Diffused:

- Opal or diffused polycarbonate sheets have a translucent, milky appearance

- They provide a soft, even light diffusion, reducing direct glare and hot spots

- Opal PC sheets are often used for lighting fixtures, partitions, and other applications requiring diffused illumination

Prepare the Installation Area:

Measure the area where you intend to install the awning to determine the required size of the polycarbonate sheets and supporting structure.

Ensure that the installation area is clean, level, and free of any obstructions.

Gather the Necessary Tools and Materials:

Polycarbonate sheets: Select the appropriate size and thickness of polycarbonate sheets for your awning.

Supporting structure: This can include metal or wood beams, brackets, and fasteners.

Tools: You may need a measuring tape, drill, screws, screwdriver, level, and a saw for cutting the polycarbonate sheets to size.

Install the Supporting Structure:

Determine the placement of the supporting structure based on the size and design of your awning.

Measure and mark the locations for the brackets or beams that will support the polycarbonate sheets.

Install the brackets or attach the beams securely to the wall or existing structure using appropriate screws and anchors.

Cut and Prepare the Polycarbonate Sheets:

Place the cut polycarbonate sheets onto the supporting structure, aligning them properly.

Pre-drill holes through the polycarbonate sheets and into the supporting structure.

Secure the polycarbonate sheets to the structure using appropriate screws or fasteners, ensuring they are evenly spaced and tightly secured.

Colors & Logo can be customized.

BSCI & ISO9001 & ISO, RoHS.

Competitive price with high quality.

10 years of quality assurance

Inspire Creative Architecture with MCLpanel

MCLpanel is professional in polycarbonate production, cut, package and installation. Our team always helps you find the best solution.

Shanghai MCLpanel New Materials Co., Ltd. is a comprehensive enterprise focusing on the PC industry for nearly 15 years, engaged in the research and development, production, sales, processing and service of polycarbonate polymer materials.

We have a high-precision PC sheet extrusion production line, and at the same time introduce UV co-extrusion equipment imported from Germany, and we use Taiwan's production technology to strictly control the production process to ensure product quality. At present, the company has Established long-term and stable cooperative relations with famous brand raw material manufacturers such as Bayer, SABIC and Mitsubishi.

Our product range covers PC sheet production and PC processing. PC sheet includes PC hollow sheet, PC solid sheet, PC Frosted sheet, PC Embossed sheet, PC diffusion board, PC flame retardant sheet, PC hardened sheet, U lock PC sheet, plug-in pc sheet, etc.

Our factory boasts cutting-edge processing equipment for polycarbonate sheet production, ensuring precision, efficiency, and high-quality results.

Our polycarbonate sheet manufacturing facility maintains ample inventory to meet customer demands promptly. With a well-managed supply chain, we ensure a consistent stock of polycarbonate sheets in various sizes, thicknesses, and colors. Our abundant inventory allows for efficient order processing and timely delivery to our valued customers.

Your vision drives our innovation. If you need something beyond our standard catalogue, we’re ready to turn your ideas into reality. Our team ensures that your specific design requirements are met with precision.

Your vision drives our innovation. If you need something beyond our standard catalogue, we’re ready to turn your ideas into reality. Our team ensures that your specific design requirements are met with precision.

1

Do polycarbonate roofs make things very hot?

A: Polycarbonate roofs do not make things very hot with energy reflective coating and excellent insulating properties.

2

Do the sheets break very easily?

A: Polycarbonate sheets are extremely impact-resistant. Thanks to their temperature and weather resistance, they have a much longer service life.

3

What will happen in the event of a fire?

A: Fire safety is one of polycarbonate's strong points. Polycarbonate sheeting is flame retardant so they are often incorporated in public buildings.

4

Are polycarbonate sheets bad for the environment?

A: Using a very recyclable and sustainable material and 20% renewable energy, polycarbonate sheets do not emit toxic substances during combustion.

5

Can I install polycarbonate sheets myself?

A: Yes. Polycarbonate sheets are particularly user-friendly and very light, be sure to protect the construction of the organizers of the film print to understandclearly explained to the operator, with particular attention to the criteria which faces outward. Must not be installed wrong.

6

How about your package?

A: Both sides with PE films, logo can be customized Kraft paper and pallet and other requirements are available.

Company Advantages

· Incorporating the latest technology, Mclpanel flat solid polycarbonate sheet shows the finest workmanship in the industry.

· The quality inspection department strictly checks quality from the raw material to the shipment process.

· Integrated QC system of Shanghai mclpanel New Materials Co., Ltd. ensures every project finish as promise.

Company Features

· With so many high-quality products such as flat solid polycarbonate sheet delivered around the world, Shanghai mclpanel New Materials Co., Ltd. has the advantage of being a truly reliable manufacturer.

· Our company has a group of skilled employees. They have the appropriate skills to improve production, including communication, computer, planning, analytical and problem-solving skills.

· Shanghai mclpanel New Materials Co., Ltd. is striving for world-class flat solid polycarbonate sheet supplier. Call now!

Application of the Product

The flat solid polycarbonate sheet of Mclpanel can be used in many industries.

Mclpanel insists on providing customers with Polycarbonate Solid Sheets,Polycarbanote Hollow Sheets,U-Lock Polycarbonate,plug in polycarbonate sheet,Plastic Processing,Acrylic Plexiglass Sheet of high quality and a one-stop solution that's comprehensive and efficient.