Focus on PC/PMMA sheet production and processing jason@mclsheet.com +86-187 0196 0126

For Aquariums Panel Polycarbonate by Mclpanel

Company Advantages

· Unique creative ideas and perfect design of panel polycarbonate often bring joy to our customers.

· It continuously set and then exceed the standard for what it should be.

· The expanded use of the product has and will continue to enable our customers to make profits.

Product Description

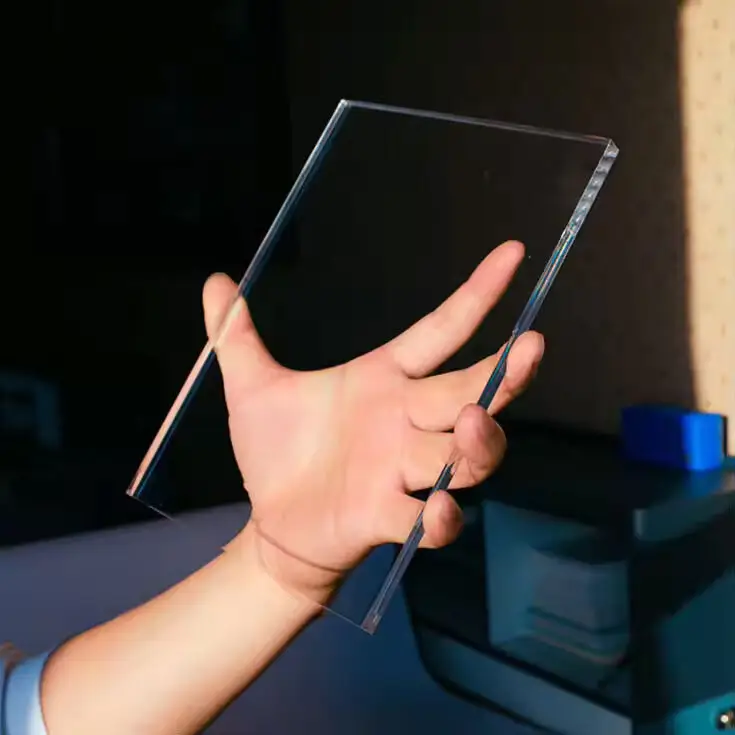

Anti-static dissipative polycarbonate sheets are a specialized type of polycarbonate material that is designed to effectively manage and dissipate static electricity buildup. Here's a more detailed explanation of what they are:

Polycarbonate Composition:

Anti-static dissipative polycarbonate sheets are made from the same base polycarbonate resin as regular polycarbonate sheets.

However, they have been formulated or treated with additional additives or coatings to impart anti-static properties.

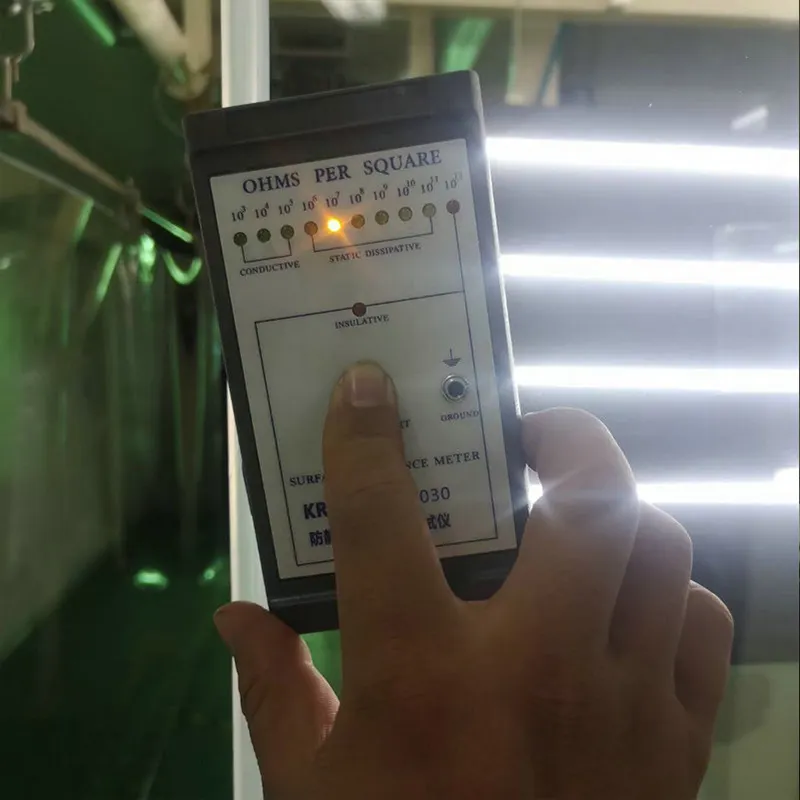

Static Electricity Management:

The key feature of anti-static dissipative polycarbonate sheets is their ability to dissipate static electricity effectively.

Static electricity can build up on the surface of materials due to triboelectric charging, which occurs when two materials come into contact and then separate.

These sheets are engineered to have a specific surface resistivity range (typically 10^6 to 10^9 ohms per square) that allows static charges to dissipate gradually, rather than building up and causing sudden, potentially harmful discharges.

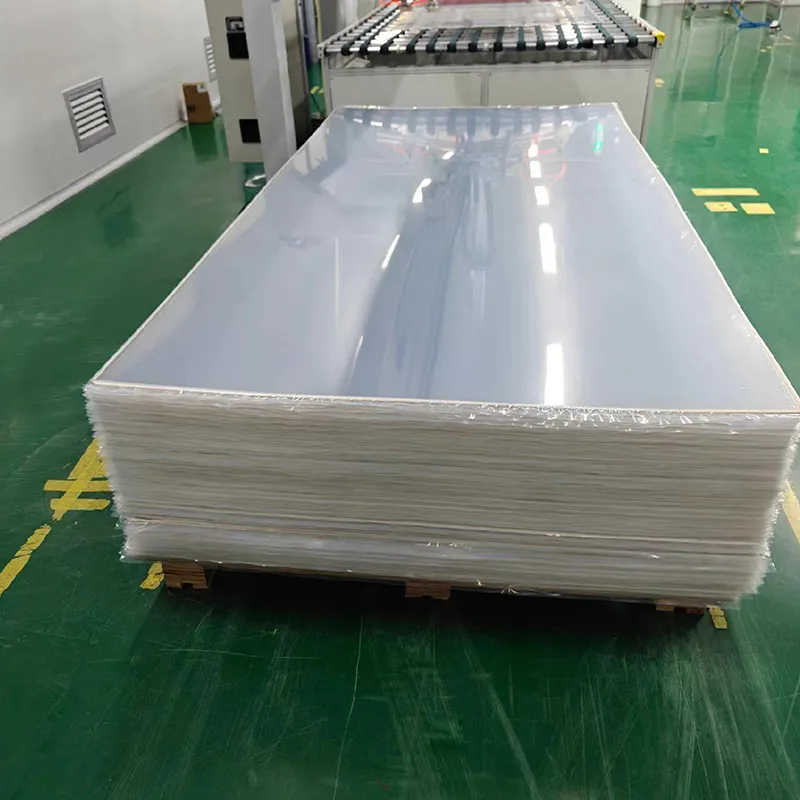

Availability and Customization:

Anti-static dissipative polycarbonate sheets are available from various manufacturers in different thicknesses, sizes, and custom color options to meet specific design requirements.

Some manufacturers may also offer additional features, such as UV protection or enhanced mechanical properties, to further tailor the sheets to the application's needs.

In summary, anti-static dissipative polycarbonate sheets are a specialized type of polycarbonate material that effectively manages and dissipates static electricity buildup, making them suitable for use in applications where static electricity management is critical.

product parameters

|

Name |

Anti Static dissipative Polycarbonate Sheet |

|

Thickness |

1.8, 2, 3, 4, 5, 8,10,15,20, 30mm (1.8-30mm) |

|

Color |

Transparent, white, opal, black, red, green, blue, yellow, etc. OEM color OK |

|

Standard size |

1220*1830, 1220*2440mm or custom |

|

Certificate |

CE, SGS, DE, and ISO 9001 |

|

Resistance value |

10^6 ~ 10^8Ω |

|

MOQ |

2 tons, can be mixed with colors/sizes/thickness |

|

Delivery |

10-25 days |

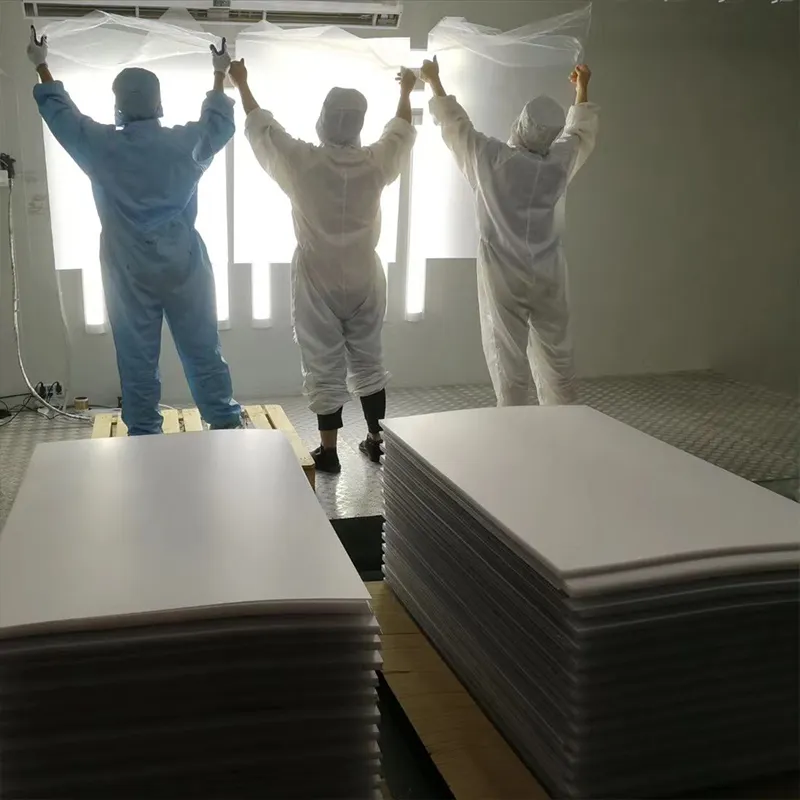

Antistatic Polycarbonate Sheet Production

The production of antistatic polycarbonate sheets involves a specialized process to impart static electricity dissipation properties to the material. This process typically includes the following key steps:

Raw Material Preparation:

The primary raw material is polycarbonate resin, which is the base material for the sheets.

Antistatic additives, such as conductive fillers or surfactants, are also carefully measured and prepared for incorporation into the polycarbonate.

Compounding:

The polycarbonate resin and antistatic additives are fed into a high-intensity mixer or extruder, where they are thoroughly blended and homogenized.

The compounding process ensures a uniform distribution of the antistatic additives throughout the polycarbonate matrix.

Extrusion:

The compounded polycarbonate material is then fed into a specialized extruder equipped with precise temperature and pressure controls.

The extruder melts and forces the polycarbonate compound through a die, shaping it into a continuous sheet or film.

product ADVANTAGE

Cannot be tribocharged when properly grounded

Prevents build-up of static charge and accumulation of harmful contamination.

Electrostatic decay in less than 0.05 second per Federal Test Standard 101C, Method 4046.1

Results in rapid static dissipation without arcing.

Surface resistivity of 106 - 108 ohms per square

Provides for ESD control without the need for ionization.

Permanence in static dissipation performance

Avoids cost of application of temporary topical anti-stats.

Humidity independent static charge control

Avoids inconvenience of maintaining high levels of humidity and damage caused by such humidity.

Advanced technology, uniform surface treatment

Avoids conductive discontinuities (charged "hot spots") often found with non-uniform temporary topical anti-stats.

Product application

Electronics Manufacturing:

- Used in the production areas and assembly lines for manufacturing electronic products, circuit boards, and other sensitive electronic components.

- Can be used to fabricate anti-static enclosures, packaging containers, and workbenches.

Semiconductor Industry:

- Used in the clean rooms and dust-free environments of semiconductor chip manufacturing, as anti-static partitions, workstations, and transportation containers.

Medical Device Manufacturing:

- Used in the production areas and clean rooms of medical device manufacturing, to fabricate anti-static enclosures and surgical room partitions.

Aerospace and Aviation:

- Used in the manufacturing areas of aerospace components and vehicles, as anti-static workbenches, containers, and partitions.

Precision Instrument and Equipment Manufacturing:

- Used in the production environments of sensitive precision instruments and equipment, as anti-static enclosures and partitions.

Laboratories and Cleanrooms:

- Used in cleanrooms, laboratories, and other dust-free controlled environments with strict static electricity requirements, for fabricating workbenches, protective shields, and other components.

Storage and Transportation:

- Used as packaging containers for storing and transporting static-sensitive electronic components, parts, and equipment.

chemical resistance

Samples immersed in the specified chemicals for 24 hours at room temperature and visually examined.

| Chemical | Surface Attack | Visual Evaluation |

| Deionized Water | None | Clear |

| 30% Sodium Hydroxide | None | Cloudy |

| 30% Sulfuric Acid | None | Clear |

| 30% Nitric Acid | Some Pitting | Clear |

| 48% Hydrofluoric Acid | Pitted Coating | Clear |

| Methanol | Slight Pitting | Clear |

| Ethanol | None | Clear |

| Isopropyl Alcohol | None | Clear |

| Acetone | Severe Pitting | Opaque |

Choose colour

Why choose us?

ABOUT MCLPANEL

Our advantage

FAQ

Company Features

· Shanghai mclpanel New Materials Co., Ltd. is a strong manufacturer of panel polycarbonate. Our capabilities step from our years of experience in designing and producing products in this field.

· Equipped with imported technology, Mclpanel has more confidence to manufacture panel polycarbonate with high quality. To improve the reputation of Mclpanel, utilizing newly advanced technology is necessary. Mclpanel masters marvellous technology to ensure the quality of panel polycarbonate.

· We have repeatedly analyzed the market demand for panel polycarbonate. Check now!

Product Comparison

Compared with other panel polycarbonate, the panel polycarbonate produced by Mclpanel has the following advantages and features.