Focus on PC/PMMA sheet production and processing jason@mclsheet.com +86-187 0196 0126

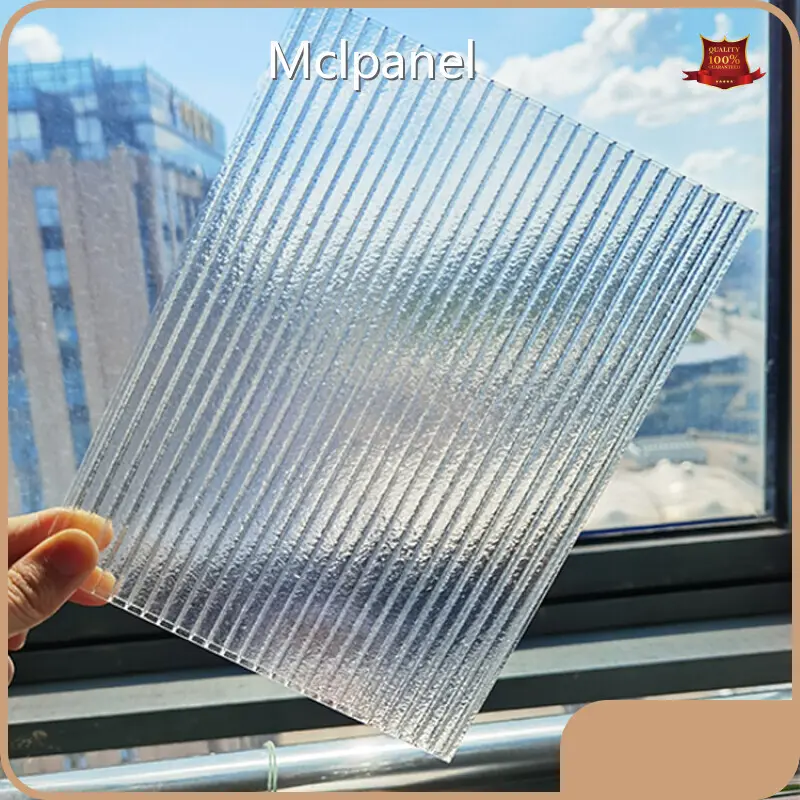

Hot Sale Cost of Polycarbonate Sheets Vendor for Home

Product details of the cost of polycarbonate sheets

Product Information

Rational construction design makes cost of polycarbonate sheets to be operated better and more smoothly. The quality of the product is consistent with the requirements of international quality standards. The product has good competition capacity and a good development prospect.

Product Description

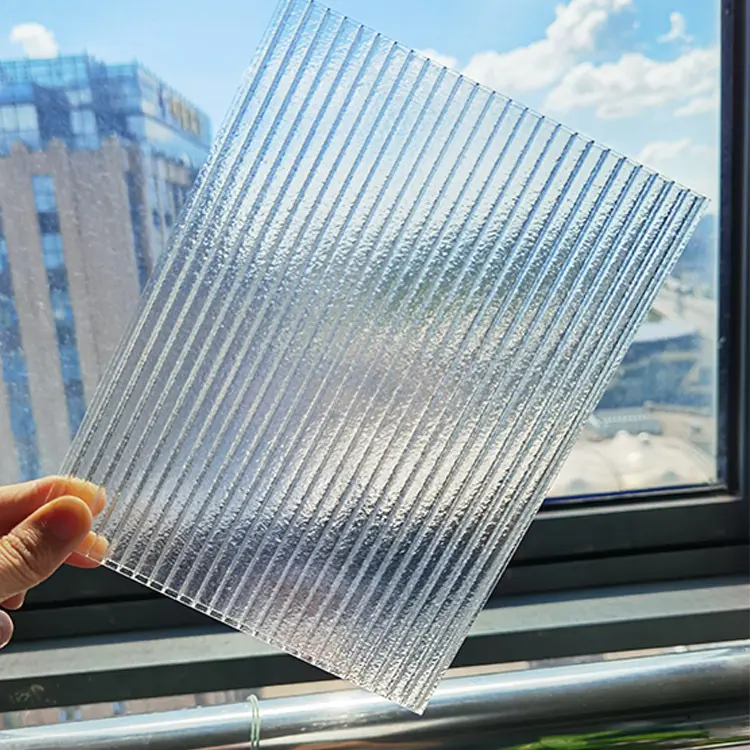

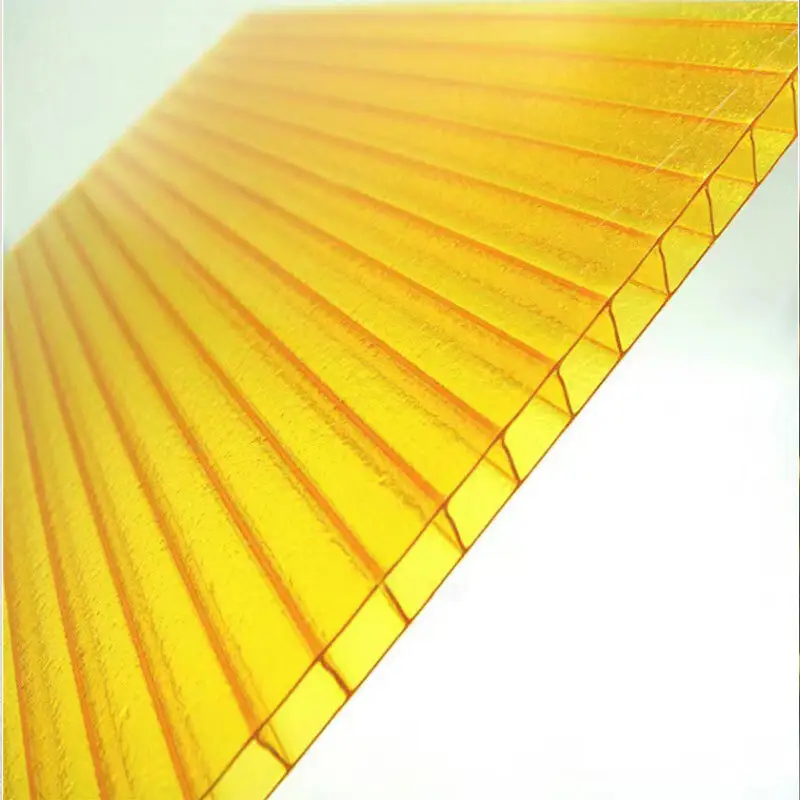

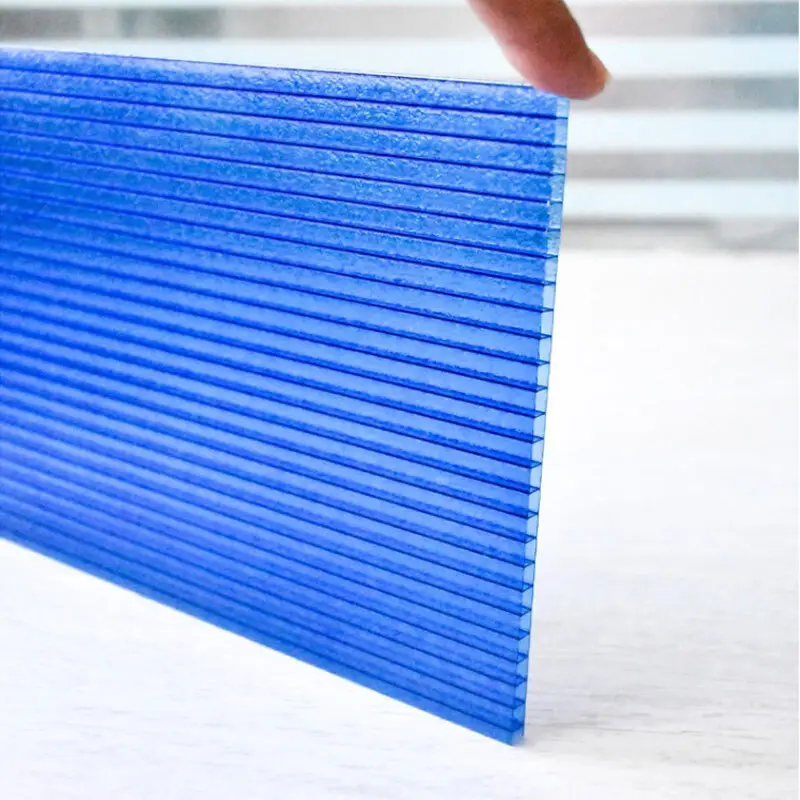

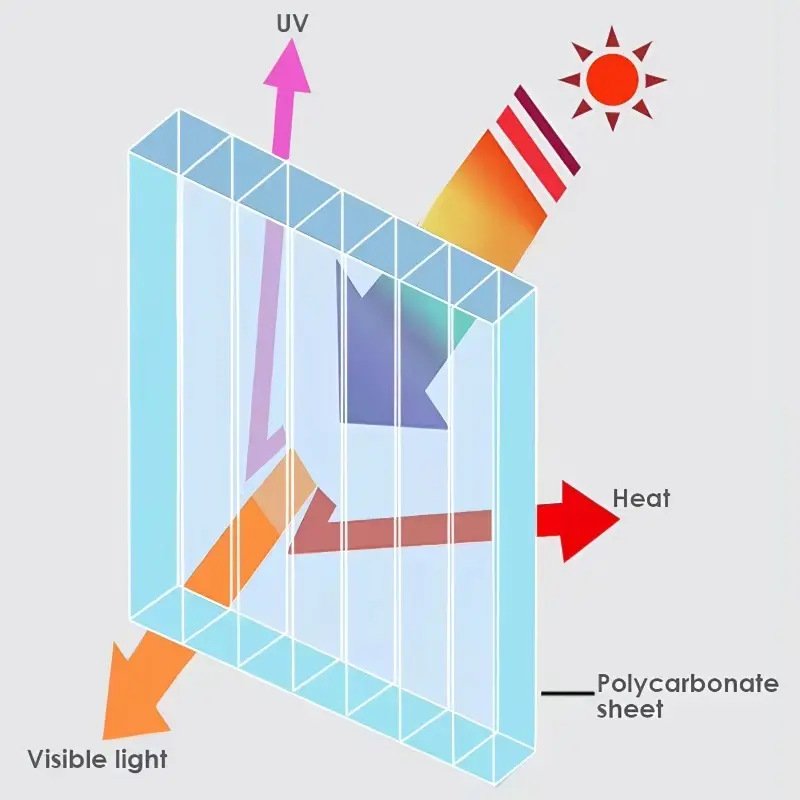

Twin-wall Frosted crystal polycarbonate hollow sheet are the main covering material for commercial greenhouses, which have the characteristics of high light transmittance, weather resistance, anti-hail, rain and snow, fire and flame retardant, lightweight, easy installation, good thermal insulation, and UV resistance. It is co-extruded with UV-resistant UV coating. It is durable for lighting without yellowing, flame retardant and heat preservation without condensation.

The frosted finish is achieved through a manufacturing process that creates a textured surface, diffusing light and providing a softer, more diffused appearance compared to clear polycarbonate.

Especially suitable for smart greenhouse projects, such as flowers, vegetables, melons, fruit trees and other planting crops that require photosynthesis. It is also used as a lighting ceiling material for ecological restaurants, soilless cultivation, leisure greenhouses and other projects.

Polycarbonate sheet parameters

| Name | PC Hollow Sheet | Material | 100% Virgin polycartonate material |

| Thickness | 4mm -40mm | Width | 2.1m , 1.22m or customized |

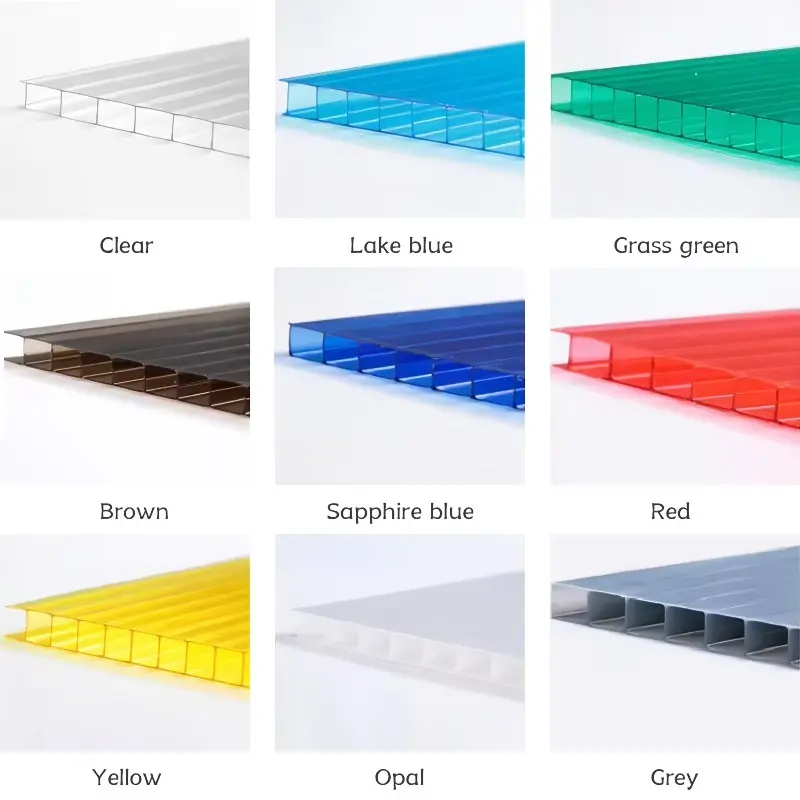

| Length: | 5.8m/11.8m/Customized | Color | Clear/Green/Brown/Blue/Milky.ect |

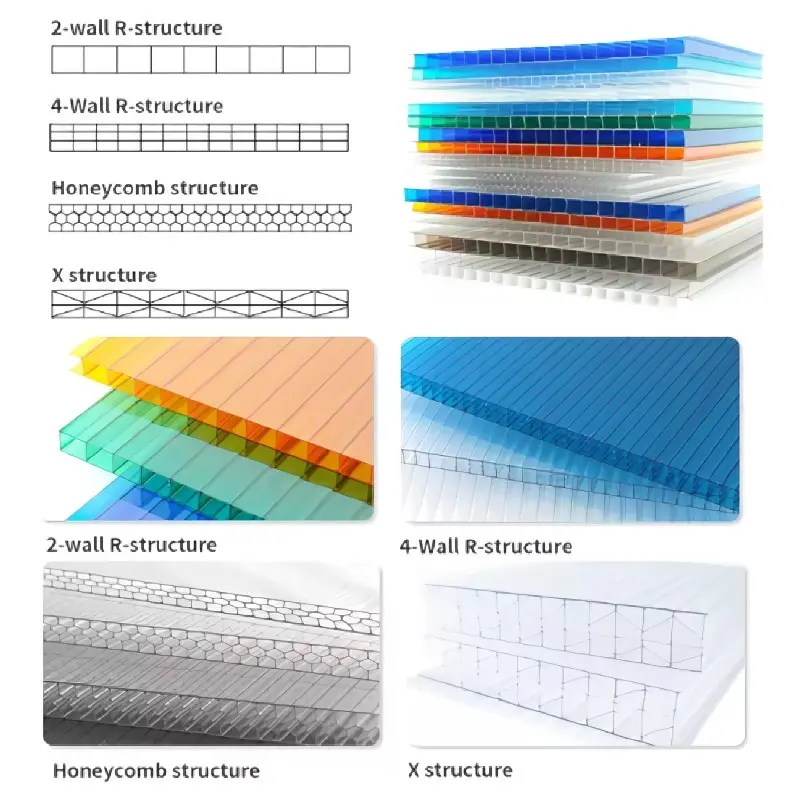

| Retardant | Grade B1 (GB Standard) | Stype | R-structure, H-structure, M-structure |

| Certification | ISO9001 & ISO 14001 | Surface | With 50 micron UV protection |

| Packaging: | Both sides with PE film, logo on the PE film. Customized package is available too. | ||

| Delivery | Within 7-10 working days once we received the deposit. | ||

| The number of containers that can be loaded | ||||

| capacity for 20 GP | 2.1m*5.8m*6mm | 400 sheet | ||

| 2.1m*5.8m*8mm | 300 sheet | |||

| 2.1m*5.8m*10mm | 240 sheet | |||

| capacity for 40 GP | 2.1m*5.8m*6mm | 800 sheet | 2.1m*11.8m*6mm | 400 sheet |

| 2.1m*5.8m*8mm | 600 sheet | 2.1m*11.8m*8mm | 300 sheet | |

| 2.1m*5.8m*10mm | 480 sheet | 2.1m*11.8m*10mm | 240 sheet | |

Polycarbonate sheet advantages

Polycarbonate sheet application

● Unusual decorations, corridors and pavilions in gardens and recreational and rest places.

● Interior and exterior decorations of commercial buildings, and curtain walls of the modern urban buildings.

● The transparent containers, front wind shields of motorcycles, airplanes, trains, ships, vehicles, motor boats, sub marines.

● Telephone booths, street name plates and sign boards.

● Instrument and war industries - windscreens, army shields.

● Walls, roofs, windows, screens and other high quality indoor decoration materials.

● Sound insulation shields on express ways and city hour highways.

● Agriculture greenhouses and sheds.

Polycarbonate sheets Features

● Exceptional resistance to harsh weather conditions (all weather resistance).

● Standard mechanical properties between -40C to and 120C.

● Light-weight and easy to carry and install.

● High quality polycarbonate resin makes them strong and durable.

● Excellent light transmission (great transparency levels).

● Outstanding thermal insulation.

● Energy efficient and cost-effective.

● Non-combustible (fire retardant property).

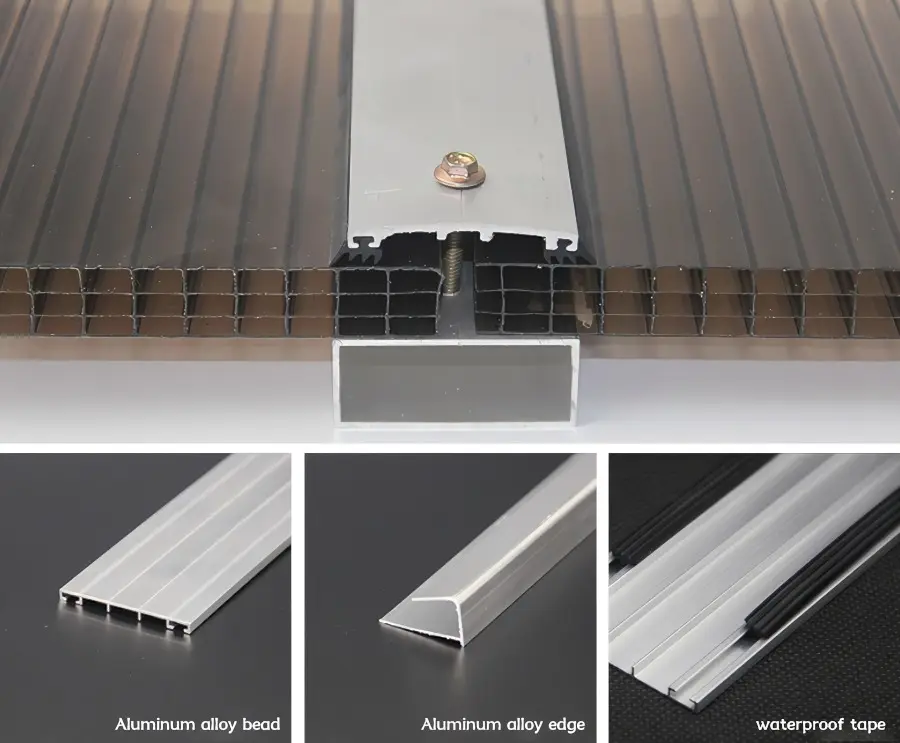

POLYCARBONATE SHEETS installation

Installing hollow polycarbonate sheet is straightforward. Start by measuring and cutting the sheets to size. Use proper support structures and secure the sheets with screws and caps. Ensure the UV-protected side faces outward.

Polycarbonate sheet video display

Discover the benefits of choosing MCLPanel Frosted hollow polycarbonate sheets in this informative video. Learn how our lightweight, durable, and highly transparent panels provide excellent thermal insulation and UV protection. Ideal for greenhouses, skylights, and various architectural applications, MCLPanel sheets offer superior impact resistance and are easy to fabricate. Watch now to see why MCLPanel is the perfect choice for your construction needs.

Why choose us?

ABOUT MCLPANEL

Why choose MCLpanel?

FAQ

Company Feature

• During the development for years, Mclpanel has mastered advanced production equipment and has accumulated rich production experience.

• We have a strong sales and service team that can answer consumer inquiries in a timely manner and help consumers properly resolve after-sales issues.

• Mclpanel's location enjoys traffic convenience with multiple traffic lines passing through. This is conducive to the outward transportation and is the guarantee of timely supply of products.

• With the comprehensive sales system, Mclpanel has a sales network covering the whole country.

Mclpanel's Polycarbonate Solid Sheets,Polycarbanote Hollow Sheets,U-Lock Polycarbonate,plug in polycarbonate sheet,Plastic Processing,Acrylic Plexiglass Sheet are all qualified by national certification. If you have any needs, please contact us as soon as possible.