Focus on PC/PMMA sheet production and processing jason@mclsheet.com +86-187 0196 0126

Long Lasting Hollow Polycarbanote Sheets Hollow Polycarbanote Sheets Company

Product details of the hollow polycarbanote sheets

Product Introduction

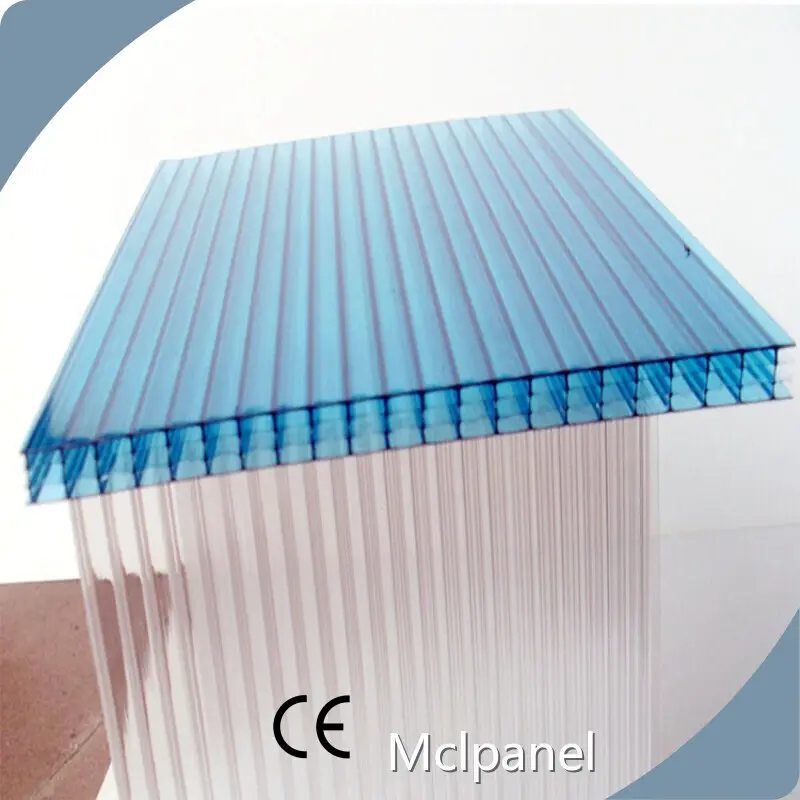

Mclpanel hollow polycarbanote sheets is known for its style, selection, and value. . hollow polycarbanote sheets offer the best performance for its price. Mclpanel is proud of building friendly relationships with new and existing business partners.

Polycarbonate plastic Sheet Description

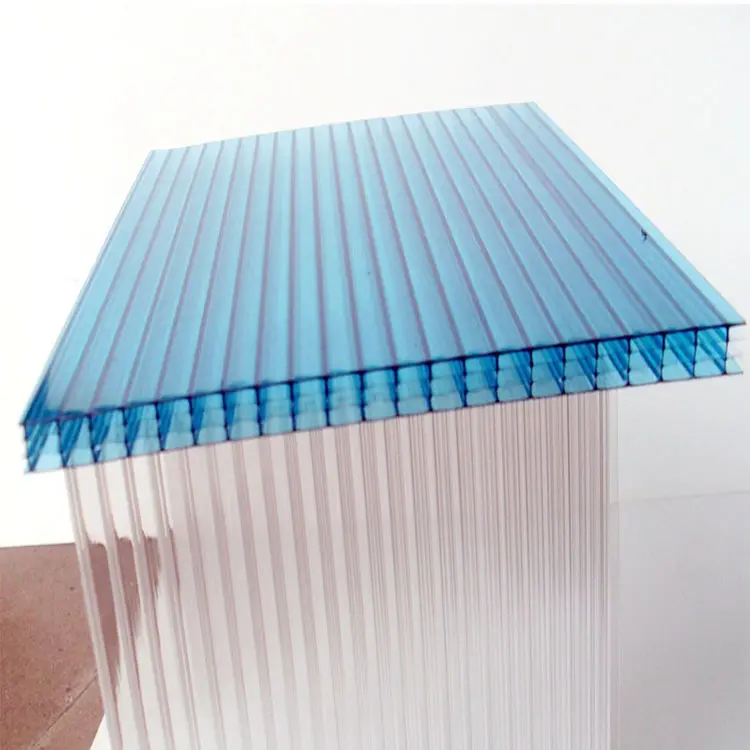

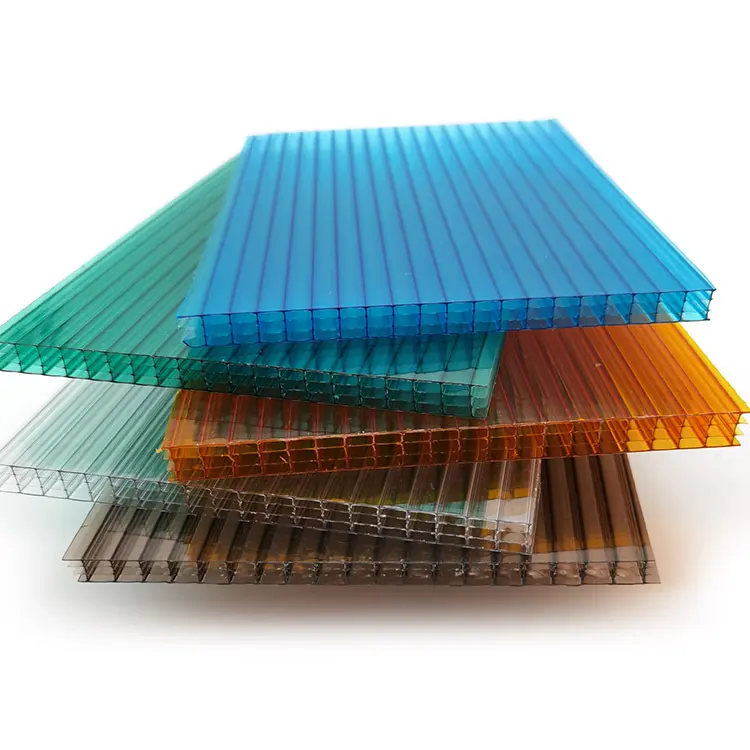

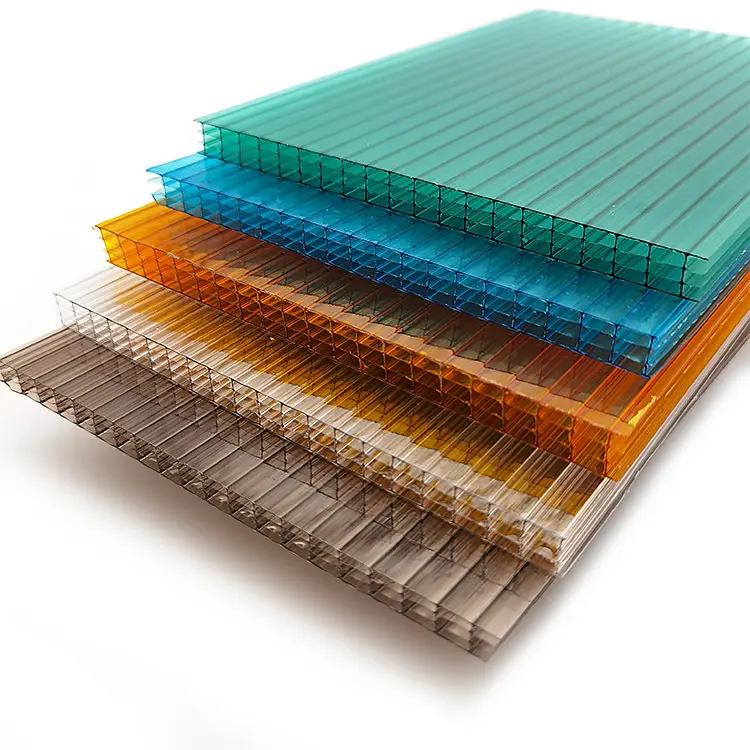

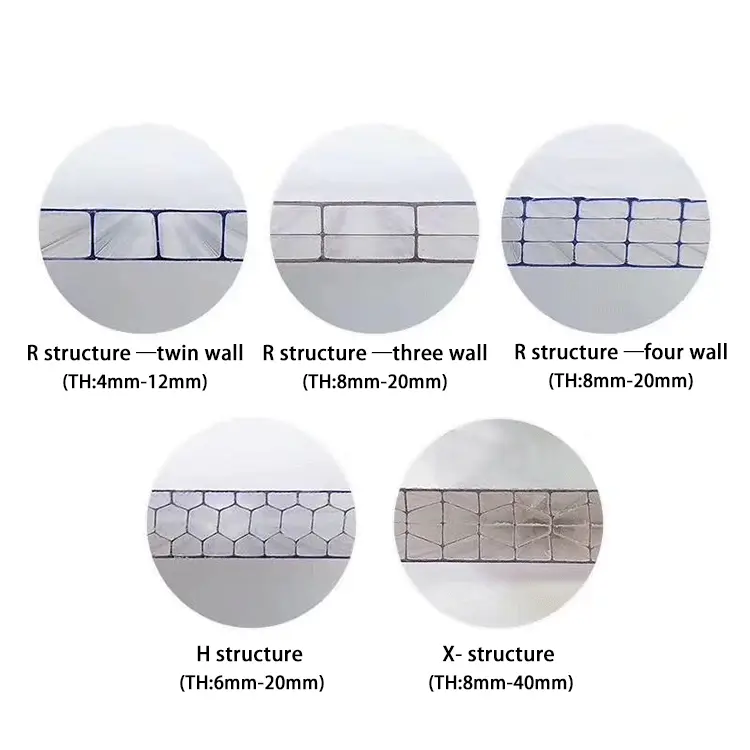

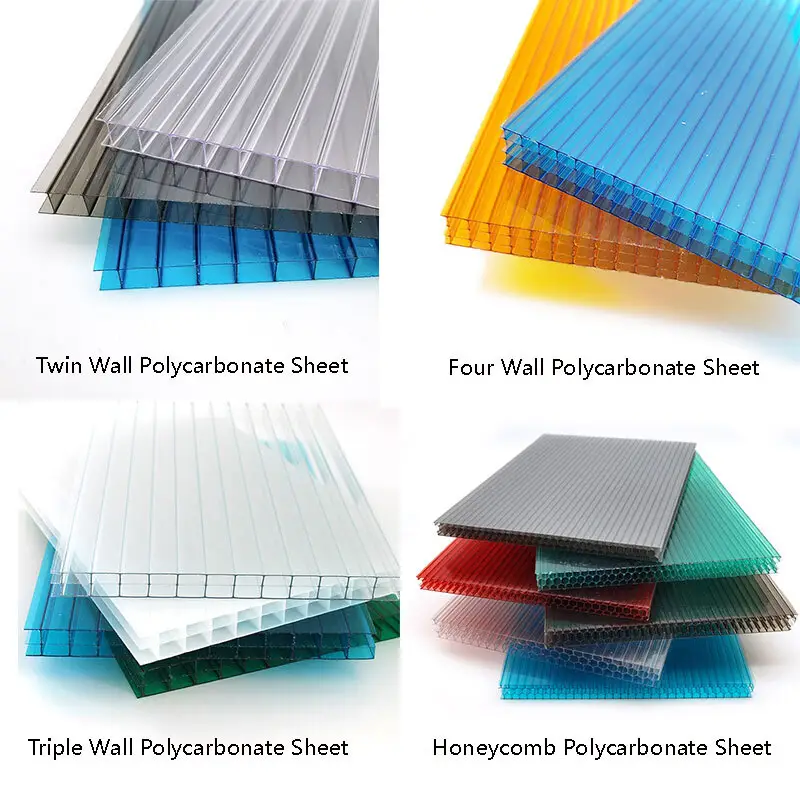

The multiwall cavity structure of the four-wall rectangular sheet provides it with excellent bearing capacity. The excellent thermal insulation property is more important. It gains a decrease of the heat conductivity (k value) by 20% compared to the triple-wall sheet with the same thickness.

In addition to a light and compact structure, the sheet is more energy efficient and environmentally friendly and has enhanced bearing capacity.

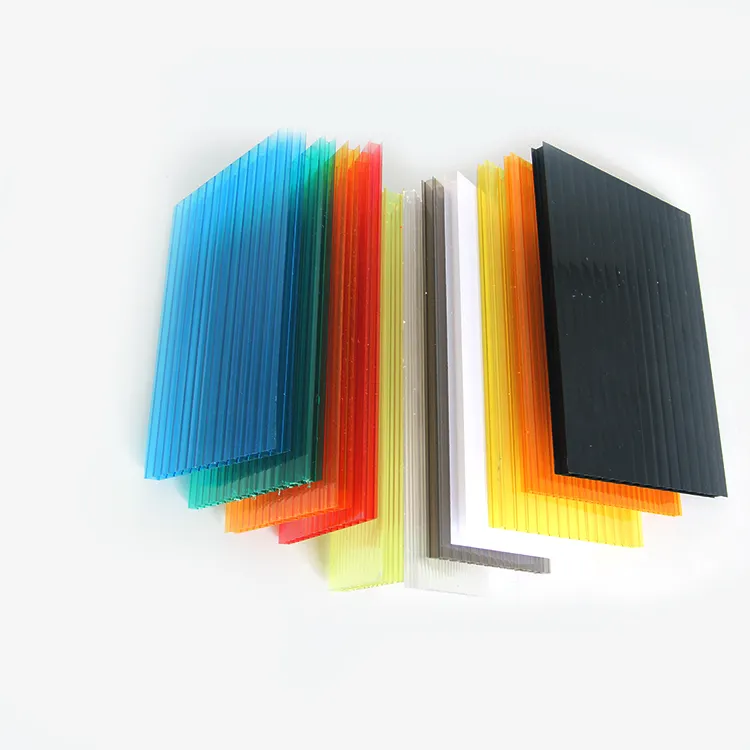

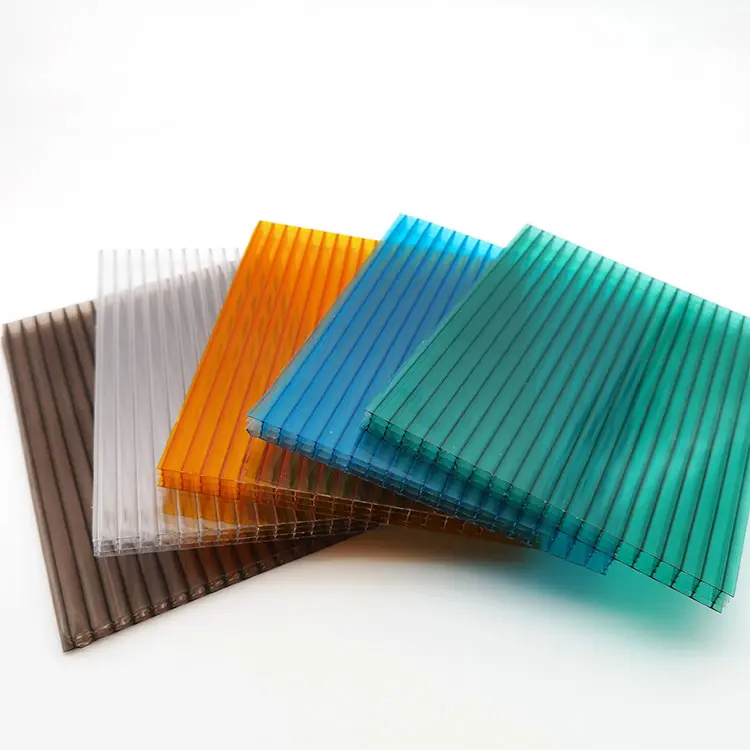

Addition of the coating whose external surface is easy to clean and has anti-dropping function at the lower layer is allowed so that its transparency can be maintained. It ensures the transmittance of visible light and infrared light while blocking UV rays so as to protect plant growth. The sheet comes in various color and thickness options.

Polycarbonate plastic Sheet parameters

|

Product Name |

Four wall polycarbonate hollow sheets |

|

Place of Origin |

Shanghai |

|

Material |

100% Virgin polycarbonate material |

|

Colors |

Clear, bronze, blue, green, opal, gray or customized |

|

Thickness |

8-20 mm or customized |

|

Width |

2.1m , 1.22m or customized |

|

Length |

5.8m/6m/ 11.8m/ 12m or customized |

|

Surface |

With 50 micron UV protection , heat resistance |

|

Retardant standard |

Grade B1 (GB Standard) Polycarbonate hollow sheet |

|

Packaging |

Both sides with PE film, logo on the PE film. Customized package is available too. |

Polycarbonate plastic Sheet FEATURES

● High thermal insulation ● Lighter weight than solid panels

● Excellent rigidity and impact resistance ● Superior structural durability

● Available in clear and a variety of tints ● Weather and UV resistant

● Easy to handle and install ● High fire performance rating

Product application

1)Unusual decorations, corridors and pavilions in gardens and recreational and rest places;

2)Interior and exterior decorations of commercial buildings, and curtain walls of the modern urban buildings;

3)The transparent containers, front wind shields of motorcycles, airplanes, trains, ships, vehicles, motor boats, sub marines;

4)Telephone booths, street name plates and sign boards;

5)Instrument and war industries - windscreens, army shields

6)Walls, roofs, windows, screens and other high quality indoor decoration materials;

7)Sound insulation shields on express ways and city overhead highways;

8)Agriculture greenhouses and sheds;

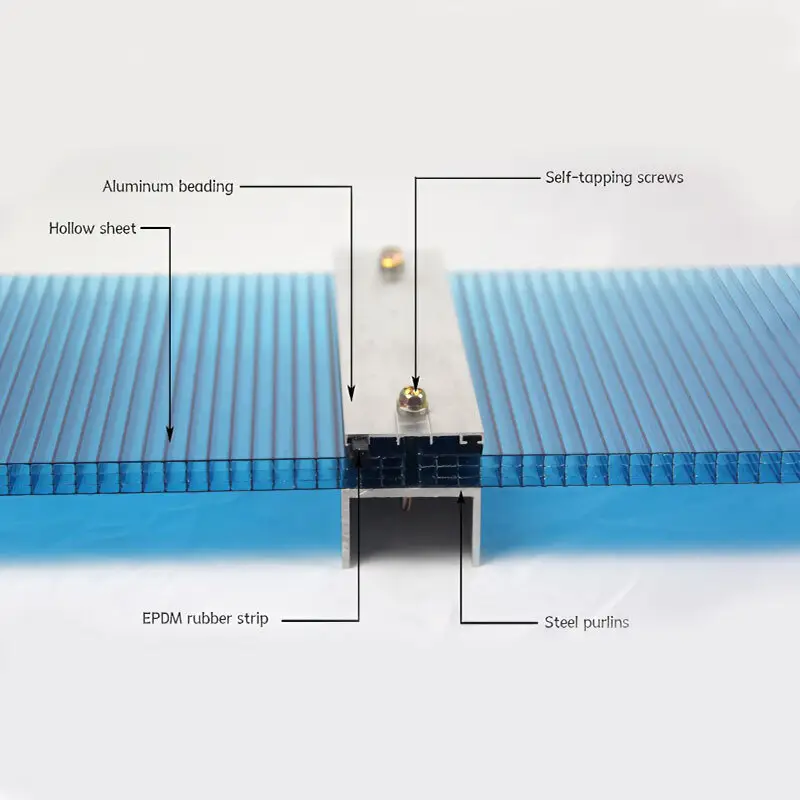

INSTALLATION

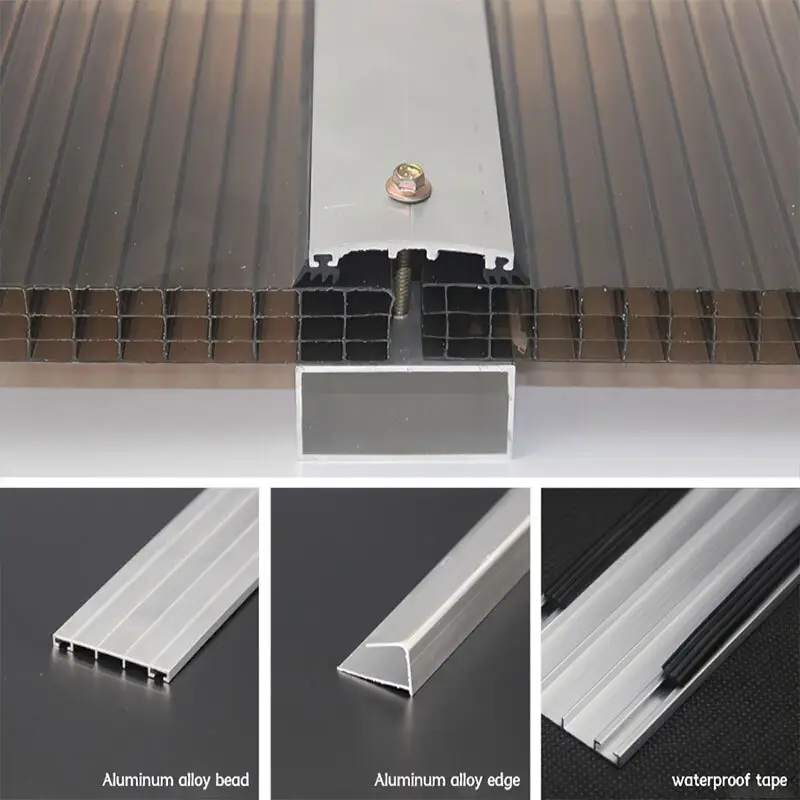

1. Measure and prepare: Measure the area where you plan to install the polycarbonateSheet to determine the required dimensions.

2. Prepare the supporting structure: Before installing the Plastic Polycarbonate Sheet make sure the supporting structure, such as a frame or rafters, is properly prepared and structurally sound.

3. Cut the Plastic Polycarbonate Sheet : Using appropriate cutting tools, carefully cut the polycarbonate Plastic Polycarbonate Sheet to the required size and shape.

4. Pre-drill holes: Along the edges of the Plastic Polycarbonate Sheet , pre-drill holes that are slightly larger than the diameter of the screws you will be using.

5. Install the PlasticPolycarbonate Sheet : Place the first sheet in position, aligning it with the supporting structure. Insert screws through the pre-drilled holes and secure the Plastic Polycarbonate Sheet to the structure.

Why choose us?

ABOUT MCLPANEL

Our advantage

FAQ

Company Feature

• Mclpanel, built in has accumulated rich experience and has established a good reputation in the industry.

• Mclpanel is located in a position that provides easy traffic condition, complete functional facilities and the superior comprehensive surroundings. All that creates advantages for the efficient transportation.

• With a focus on service quality, Mclpanel guarantees the service with a standardized service system. Customer's satisfaction would be improved by the management of their expectations. Their emotions will be comforted through professional guidance.

Our products are of excellent quality and favorable price, winning a wide recognition. If you want to know more about the products, please contact us!