Focus on PC/PMMA sheet production and processing jason@mclsheet.com +86-187 0196 0126

Polycarbonate Sheet Frosted - Company - Mclpanel

Company Advantages

· Mclpanel polycarbonate sheet frosted is made from durable raw materials with good properties.

· The product is durable, functional, and practical.

· By introduction of sophisticated production equipment and facilities, Shanghai mclpanel New Materials Co., Ltd. can guarantee quality of polycarbonate sheet frosted.

Product Description

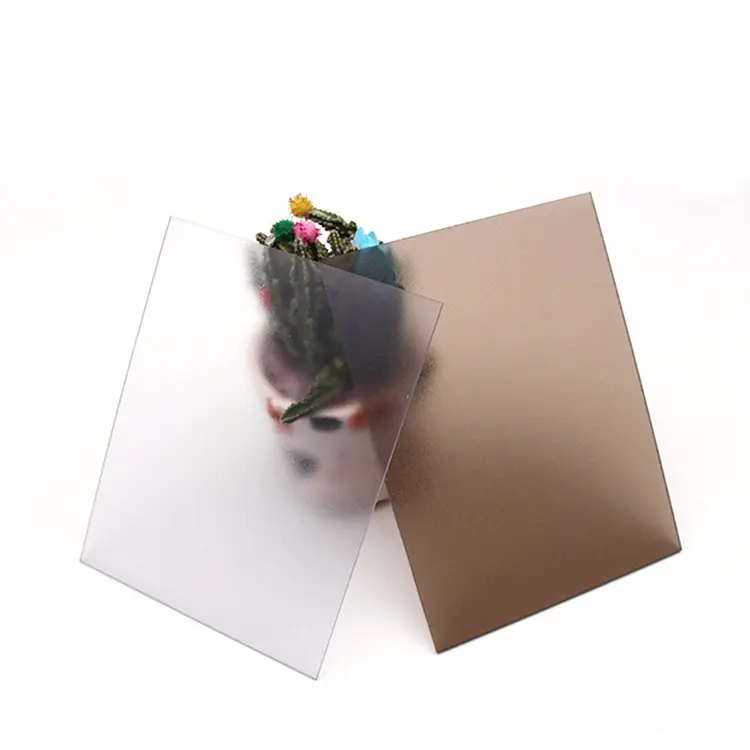

Elevating Designs with Polycarbonate Satin Panels

In our state-of-the-art facility, we proudly manufacture a range of high-quality polycarbonate (PC) satin finish panels that offer a unique aesthetic and functional benefits. These matte-textured PC sheets are engineered to provide a soft, diffused appearance while maintaining the inherent clarity and durability of polycarbonate.

The satin-finished PC panels are ideal for applications where a more subtle, understated look is desired, such as in architectural interiors, specialty lighting fixtures, and modern furniture design. The matte surface finish diffuses light in a visually pleasing manner, creating a sense of warmth and sophistication.

Beyond their aesthetic appeal, the polycarbonate satin panels also offer practical advantages. The textured surface helps to conceal minor scratches and imperfections, making them a low-maintenance option for high-traffic environments. Additionally, the satin finish provides a subtle anti-glare effect, enhancing visual comfort in brightly lit spaces.

Leveraging our advanced manufacturing techniques, we are able to consistently produce PC satin panels that maintain exceptional optical clarity and dimensional stability. This ensures the material can be seamlessly integrated into a wide range of design applications, from modern retail displays to sleek architectural elements.

Customers across diverse industries rely on our polycarbonate satin panels to elevate their products and spaces, creating visually striking and functionally superior solutions that captivate their audiences.

product parameters

|

thickness |

2.5mm-10mm |

|

Sheet Size |

1220/1820/ 1560/2100*5800mm(Width*Length) |

|

1220/1820/ 1560/2100*11800mm(Width*Length) |

|

|

Color |

Clear/ Opal /Light Green/ Green/ Blue/ Lake Blue/Red/ Yellow And So On. |

|

Weight |

From 2.625kg/m² To 10.5kg/m² |

|

Lead Time |

7 Days One Container |

|

MOQ |

500 Square Meter For Each Thickness |

|

Packing Details |

Protective Film On Both Sides Of Sheet+Waterproof Tape |

Product advantages

Product application

● LED light cover: The led light diffuser sheet Ideal for protecting and enhancing LED light displays.

● Signage: Perfect for use in illuminated signage.

● Skylight: Can be used to diffuse natural light in skylights.

● Ceiling light diffuser: Helps to create comfortable, evenly distributed lighting from ceiling fixtures.

● Light box: Used in light boxes to provide a soft and uniform illumination.

● Portable Traffic signal: Often employed in traffic signal equipment due to its durability and clarity.

Color

Clear/Translucent:

- Matte clear or translucent polycarbonate sheets provide a soft, diffused light transmission without the high gloss of a glossy surface.

- This makes them suitable for applications where glare reduction and light diffusion are desired, such as in lighting fixtures or partitions.

Opal or Milky White:

- Opal or milky white matte polycarbonate sheets have a translucent, opaque appearance that provides excellent light diffusion.

- They are commonly used for lighting diffusers, privacy screens, and decorative panels.

Tinted Colors:

- Matte polycarbonate sheets can be produced with various tinted color options, such as gray, bronze, blue, or green.

- These tinted matte sheets are useful for applications where enhanced privacy, glare reduction, or specific aesthetic effects are required.

Why choose us?

ABOUT MCLPANEL

Our advantage

FAQ

Company Features

· Shanghai mclpanel New Materials Co., Ltd. has its own advantage to produce polycarbonate sheet frosted with high quality.

· Our manufacturing plant is the heart of our business. It has been crafting high-quality products in an environment dedicated to excellence and safety. Our factory is located in a strategical place. It has proximity and connectivity with airport, seaports, and a network of roads with adequate logistics framework.

· We are serious about our customers. Our goal is to be a courteous and professional manufacturer to provide the best manufacturing services for our customers.

Application of the Product

Mclpanel's polycarbonate sheet frosted is widely used in the industry and is widely recognized by customers.

Mclpanel provides comprehensive and reasonable solutions based on customer's specific situations and needs.