Focus on PC/PMMA sheet production and processing jason@mclsheet.com +86-187 0196 0126

Polycarbonate Sheet Price Mclpanel Manufacture

Product details of the polycarbonate sheet price

Quick Detail

While designing Mclpanel polycarbonate sheet price, we uphold the principles of innovation and functionality. The product is 100% qualified as our quality control program has eliminated all defects. Mclpanel's polycarbonate sheet price is widely used in various scenes. The product is really treasured by our customers for its consistent position in the market.

Product Information

After improvement, the polycarbonate sheet price produced by Mclpanel is more brilliant in the following aspects.

Product Description

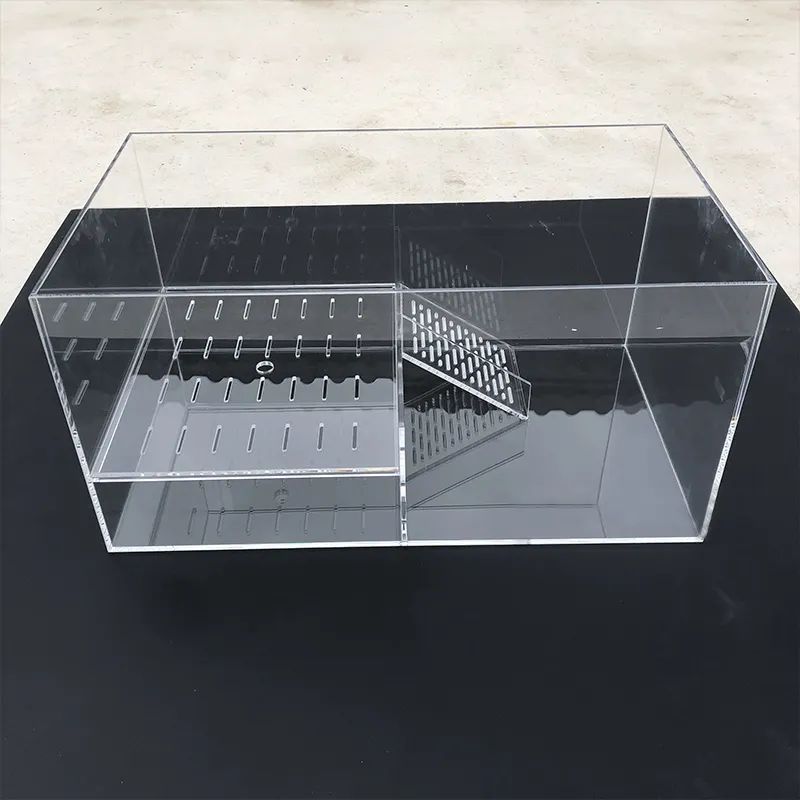

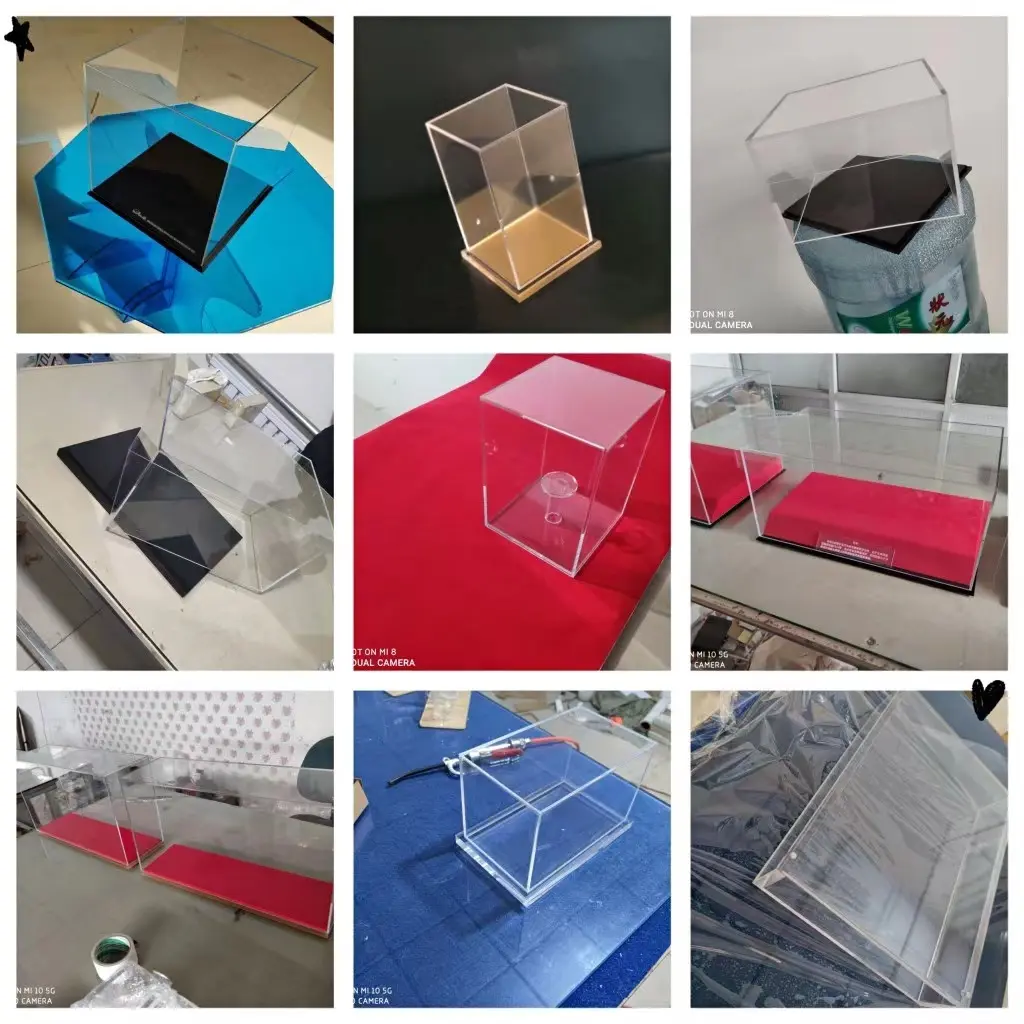

Acrylic/Polycarbonate bonding boxes are a specialized type of enclosure or housing made from clear acrylic sheets that are precisely cut and bonded together using a variety of adhesives. These boxes are designed to provide a durable, transparent, and customizable solution for a wide range of applications, from product display and packaging to prototyping and scientific equipment.

Key Features and Applications of Bonding Boxes:

Transparency: The inherent clarity of acrylic allows for unobstructed visibility of the contents within the box, making it an ideal choice for display and showcasing applications.

Customizability: Acrylic/Polycarbonate can be easily cut, shaped, and engraved, enabling the creation of custom-designed boxes to meet specific size, shape, and style requirements.

Product Display: Acrylic/Polycarbonate bonding boxes are commonly used to create attractive and secure display cases for showcasing various products, such as jewelry, collectibles, electronics, and other valuable items.

Packaging and Protection: These boxes provide a durable and protective enclosure for delicate or valuable items, making them suitable for packaging and transportation applications.

product parameters

|

Characterics |

Unit |

Data |

|

Impact strength |

J/m |

88-92 |

|

Light transmission |

% |

50 |

|

Specify Gravity |

g/m |

1.2 |

|

Elongation at break |

% |

≥130 |

|

Coefficient thermal expansion |

mm/m℃ |

0.065 |

|

Service temperature |

℃ |

-40℃~+120℃ |

|

Heat conductively |

W/m²℃ |

2.3-3.9 |

|

Flexural strength |

N/mm² |

100 |

|

Modulus of elasticity |

Mpa |

2400 |

|

Tensile strength |

N/mm² |

≥60 |

|

Soundproof index |

dB |

35 decibel decrease for 6mm solid sheet |

PRODUCT advantage

Choose us, and we promise to do everything needed to ensure a successful and satisfactory working partnership. Key Features of Acrylic Bonding Boxes

Product application

Product Display and Showcasing:

- Acrylic/polycarbonate's transparency allows for unobstructed visibility, making these boxes ideal for displaying and showcasing a variety of products, such as:

- Jewelry and accessories

- Collectibles and memorabilia

- Electronics and gadgets

- Art and decorative items

- The customizable nature of acrylic boxes enables the creation of visually appealing and attention-grabbing displays.

- Acrylic/polycarbonate's transparency allows for unobstructed visibility, making these boxes ideal for displaying and showcasing a variety of products, such as:

Packaging and Protection:

- Acrylic/polycarbonate bonding boxes provide a durable and protective enclosure for delicate or valuable items, ensuring safe transportation and storage.

- These boxes are commonly used for packaging:

- Fragile electronics and devices

- Luxury and high-end products

- Sensitive medical or scientific equipment

- The lightweight and scratch-resistant properties of acrylic make it a suitable material for packaging applications.

Prototyping and Modeling:

- Acrylic/polycarbonate's ease of fabrication and modification makes it a popular choice for creating functional prototypes and scale models in various industries.

- Acrylic/polycarbonate bonding boxes are used for:

- Product design and development

- Architectural and engineering modeling

- Educational and scientific demonstrations

Scientific and Educational Applications:

- Acrylic/polycarbonate bonding boxes are utilized in educational settings for science experiments, demonstrations, and hands-on activities.

- In the scientific and research fields, these boxes are employed as:

- Enclosures for specialized equipment

- Containment systems for experiments and tests

- Observation chambers for biological or chemical processes

Furniture and Decor:

- Acrylic/polycarbonate is increasingly being used in furniture and home decor applications, with acrylic bonding boxes serving as:

- Table tops and shelves

- Storage units and display cases

- Decorative elements like vases and light fixtures

- Acrylic/polycarbonate is increasingly being used in furniture and home decor applications, with acrylic bonding boxes serving as:

common processing

Acrylic/polycarbonate is a versatile material that can be processed using a variety of common manufacturing techniques. Here are some of the most common acrylic fabrication and processing methods:

Cutting and Shaping:

- Laser Cutting: Precise and clean cuts can be achieved using computer-controlled laser cutting machines.

- CNC Machining: Computer Numerical Control (CNC) milling and routing machines can be used to cut complex shapes and profiles in Acrylic/polycarbonate.

Bonding and Joining:

- Adhesive Bonding: Acrylic/polycarbonate can be joined using various adhesives, such as cyanoacrylate (super glue), epoxy, or acrylic-based cements.

- Solvent Bonding: Solvents like methylene chloride or acrylic-based cements can be used to chemically weld acrylic parts together.

Bending and Forming:

- Thermoforming: Acrylic/polycarbonate sheets can be heated and formed into various shapes using molds or bending jigs.

- Cold Bending: Acrylic/polycarbonate can be bent and shaped at room temperature, particularly for simple curves and angles.

- Flame Bending: Carefully applying a flame to the Acrylic/polycarbonate surface can soften the material, allowing it to be bent and shaped.

Printing and Decoration:

- Screen Printing: Acrylic/polycarbonate sheets can be screen printed with various inks and graphics to add visual interest or branding.

- Digital Printing: Wide-format digital printers can be used to directly print images, text, or graphics directly onto acrylic surfaces.

Why choose us?

ABOUT MCLPANEL

Our advantage

FAQ

Company Introduction

Mclpanel is unique in being able to quickly respond to polycarbonate sheet price, while providing quality assurance. Complete production and testing equipment are owned by Mclpanel's factory. We hold the belief that through persistent efforts, Mclpanel will thrive in polycarbonate sheet price industry. Get more info!

Don't forget to contact us to order.