Focus on PC/PMMA sheet production and processing jason@mclsheet.com +86-187 0196 0126

Polycarbonate Sheets Mclpanel Company

Product details of the Polycarbonate Sheets

Product Overview

Mclpanel Polycarbonate Sheets follows the measures and procedures of production. This product must go through our quality inspector's internal quality assurance procedure to ensure non-defective quality. Except for its good quality, our Polycarbonate Sheets is also famous among customers for its service.

Product Introduction

Compared with other same kind of products, Polycarbonate Sheets produced by Mclpanel has the following advantages and features.

Product Description

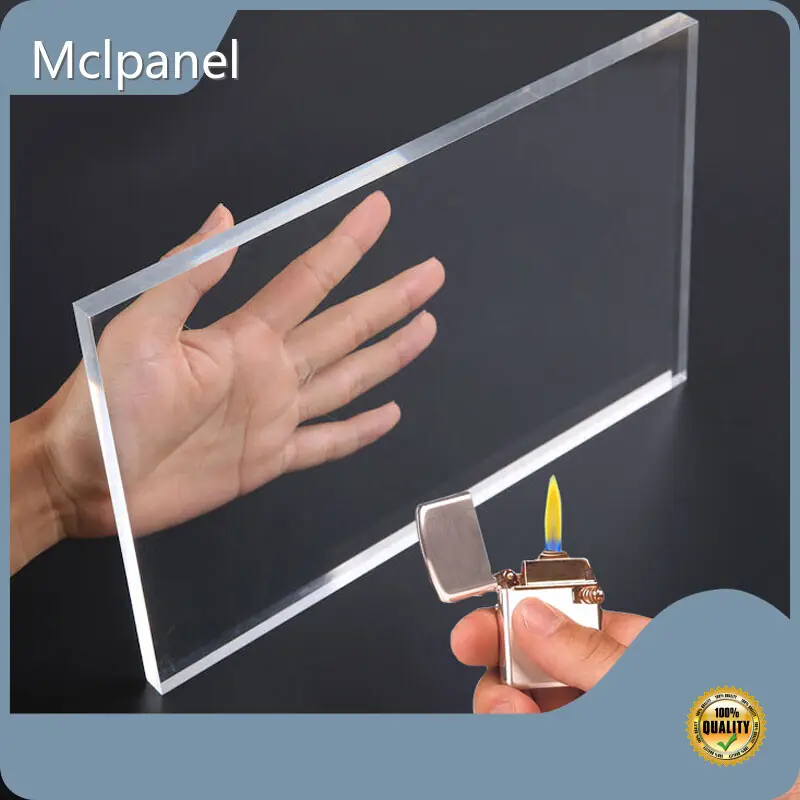

The key features of Flame Retardant polycarbonate sheets include:

Improved Flammability Resistance:

The sheets contain flame retardant additives that make them more difficult to ignite and slow the spread of flames.

They are designed to meet stringent fire safety standards and building codes.

Reduced Smoke and Toxicity:

During a fire, FR polycarbonate emits lower levels of smoke and toxic fumes compared to standard polycarbonate.

This helps maintain visibility and air quality, facilitating safer emergency evacuation.

Structural Integrity:

The flame retardant formulation helps the sheets maintain their structural integrity for longer periods under fire conditions.

This provides more time for people to evacuate and for emergency responders to intervene.

Mechanical Properties:

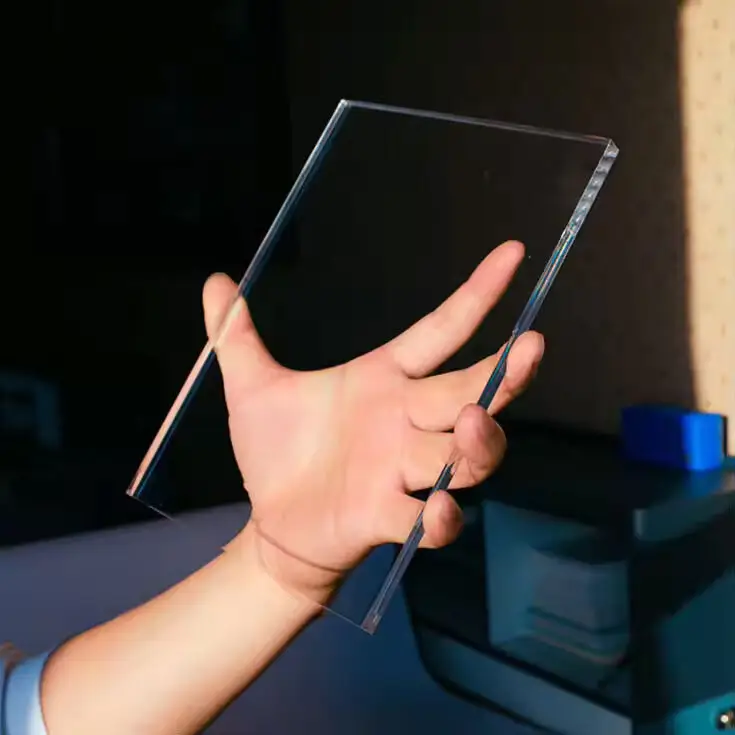

Flame Retardant polycarbonate sheets retain the excellent impact resistance, dimensional stability, and optical clarity of standard polycarbonate.

They can be fabricated using similar techniques like cutting, drilling, thermoforming, etc.

Building and construction (glazing, partitions, roofing)

Transportation (bus/train windows, aircraft interiors)

Electrical enclosures and control panels

Furnishings and fixtures in commercial/public spaces

The specific flame retardant additives and performance ratings can vary depending on the manufacturer and target application requirements, often meeting standards such as UL94, ASTM E84, or EN 13501.

product parameters

|

Name |

Flame Retardant polycarbonate sheet |

|

Thickness |

1.8, 2, 3, 4, 5, 8,10,15,20, 30mm (1.8-30mm) |

|

Color |

Transparent, white, opal, black, red, green, blue, yellow, etc. OEM color OK |

|

Standard size |

1220*1830, 1220*2440, 1050*2050, 2050*3050, 1220*3050 mm |

|

Certificate |

CE, SGS, DE, and ISO 9001 |

|

Model Number |

UL-94 v0 v1 v2 |

|

MOQ |

2 tons, can be mixed with colors/sizes/thickness |

|

Delivery |

10-25 days |

product Advantages

Production Process

The production of fire-retardant polycarbonate materials involves a carefully controlled and regulated process to ensure the desired level of flame resistance. This process typically includes the following key steps:

Raw Material Preparation:

The primary raw materials for fire-retardant polycarbonate production include polycarbonate monomers, such as methyl methacrylate, and various fire-retardant additives.

The raw materials are carefully selected and measured to achieve the required composition and properties of the final polycarbonate product.

Polymerization:

The polycarbonate monomers and fire-retardant additives are subjected to a polymerization process, often using a free-radical initiated method.

This process involves the use of initiators, catalysts, and controlled temperature and pressure conditions to facilitate the formation of high-molecular-weight polycarbonate polymers.

Compounding and Extrusion:

The polymerized polycarbonate material is then compounded with additional fire-retardant additives, such as halogenated compounds, phosphorus-based compounds, or inorganic fillers.

The compounded material is then fed into an extruder, where it is heated, melted, and homogenized to ensure a uniform distribution of the fire-retardant additives.

Sheet or Panel Forming:

The molten, fire-retardant polycarbonate compound is then extruded or cast into sheets or panels of the desired thickness and dimensions.

This process may involve the use of specialized equipment, such as calendar rolls or casting tables, to achieve the required surface finish and dimensional accuracy.

test report

Mclpanel rated to UL 94 HB. Flame Retardant polycarbonate sheet is rated UL 94 V-0 for 90 mils and above and V-2 for 34-89 mils.

Product application

Building and Construction:

- Glazing and windows

- Skylights and canopies

- Partitions and dividers

- Cladding and façade panels

- Roofing and overhead structures

Transportation:

- Bus, train, and subway windows

- Aircraft cabin interiors

- Marine vessel interiors

- Recreational vehicle components

Electrical and Electronics:

- Electrical enclosures and control panels

- Circuit breaker housings

- Switchgear and transformer covers

- Lighting fixtures and diffusers

Commercial and Public Spaces:

- Retail store fixtures and displays

- Furniture and furnishings

- Hospitality and restaurant applications

- Educational and healthcare facilities

Industrial Applications:

- Safety guards and machine enclosures

- Chemical storage and containment

- Pharmaceutical and cleanroom equipment

CUSTOM TO SIZE

Cutting:

- Cutting to Size: Polycarbonate sheets can be cut to the desired size using various methods, such as:

- Circular saws or table saws with fine-toothed blades designed for plastics

- CNC (Computer Numerical Control) routers or laser cutters for precise, custom shapes

- Manual scoring and snapping for simple straight-line cuts

- Cutting to Size: Polycarbonate sheets can be cut to the desired size using various methods, such as:

Trimming and Edging:

- Edge Finishing: The edges of the cut polycarbonate sheets can be finished using techniques like:

- Grinding or sanding to smooth the edges

- Applying edge treatments, such as decorative edge moldings or polished edges

- Edge Finishing: The edges of the cut polycarbonate sheets can be finished using techniques like:

Drilling and Punching:

- Holes and Openings: Polycarbonate sheets can be drilled or punched to create holes, slots, or other openings as required for the application.

- Specialized drill bits and punches designed for plastics are typically used to prevent cracking or chipping.

Thermoforming:

- Complex Shapes: Polycarbonate sheets can be thermoformed into various three-dimensional shapes, such as curved or contoured panels, using specialized molds and heating equipment.

- This process allows for the creation of custom-shaped parts from flat sheets.

Why choose us?

ABOUT MCLPANEL

Our advantage

FAQ

Company Information

Shanghai mclpanel New Materials Co., Ltd., which is referred to as Mclpanel, is a diversified company mainly engaged in the management of Polycarbonate Solid Sheets,Polycarbanote Hollow Sheets,U-Lock Polycarbonate,plug in polycarbonate sheet,Plastic Processing,Acrylic Plexiglass Sheet. In the following days, Mclpanel will always abide by the business philosophy of 'based on integrity, win by quality'. In addition, we keep promoting our enterprise spirit of 'exploring and progressing, changing through innovations'. We are committed to becoming a leader in the industry with international influence, therefore, we make use of our own resource advantages to improve brand building and core competitiveness. Mclpanel has an elite team with high overall quality and strong ability. At the same time, we cooperate closely with various universities and invite many experts for guidance. All this provides a good guarantee for the development. Mclpanel has a team of experienced professionals, mature technology and a sound service system. All this can provide customers with one-stop solutions.

Our products are of excellent quality and favorable price, please feel free to contact us for quotation!