Focus on PC/PMMA sheet production and processing jason@mclsheet.com +86-187 0196 0126

Wholesale Transparent Polycarbonate Sheet Mclpanel Brand

Product details of the transparent polycarbonate sheet

Product Information

During the manufacturing of Mclpanel transparent polycarbonate sheet, the source of raw materials is secured. These materials are purchased from some of the most top grade suppliers with good reputation. As our quality control procedures eliminate all defects, the products are 100% qualified. The product can meet the expectations of most customers.

Product Description

Polycarbonate Hollow Panels is also known as carbines a kind of engineering plastic panel with excellent comprehensive performance.

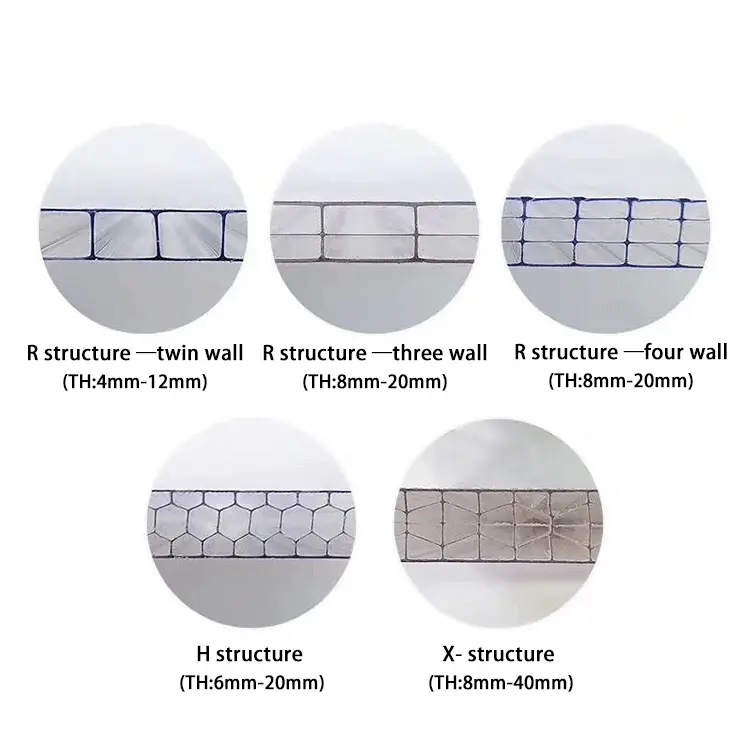

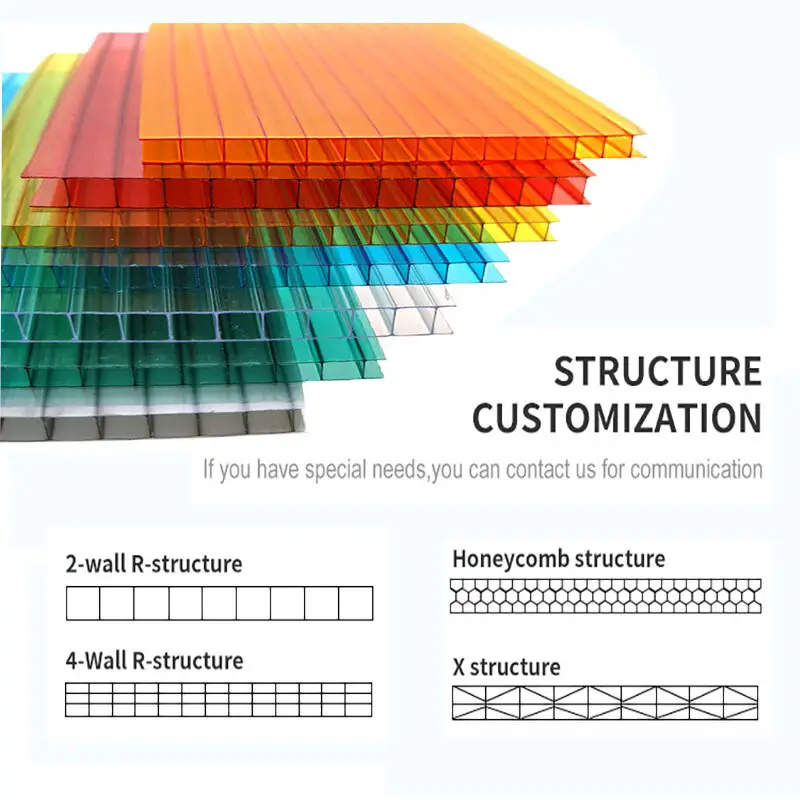

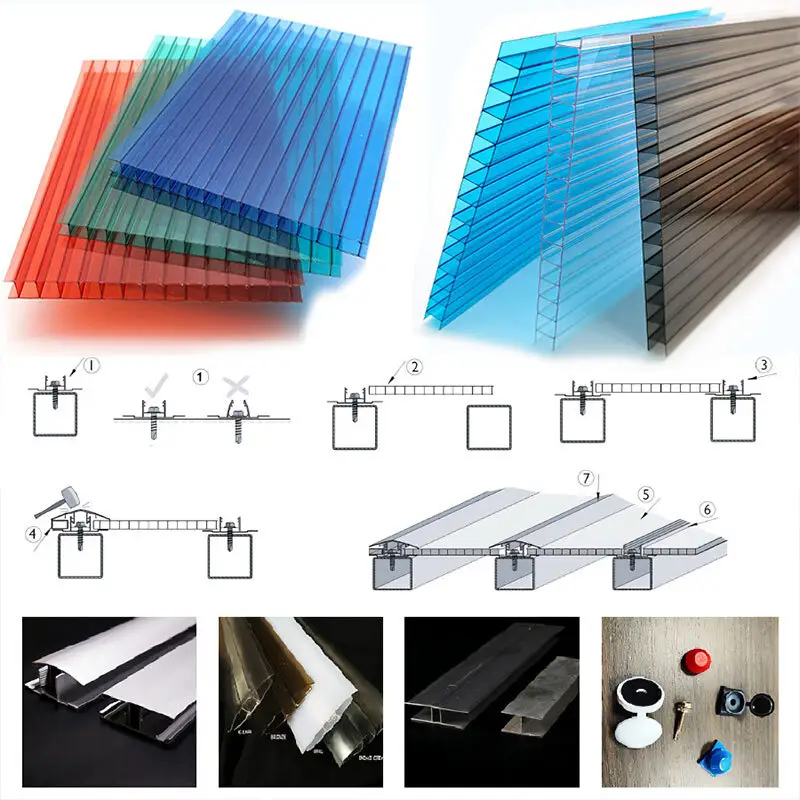

mclpanel Multiwall and Twinwall Polycarbonate Hollow Panels

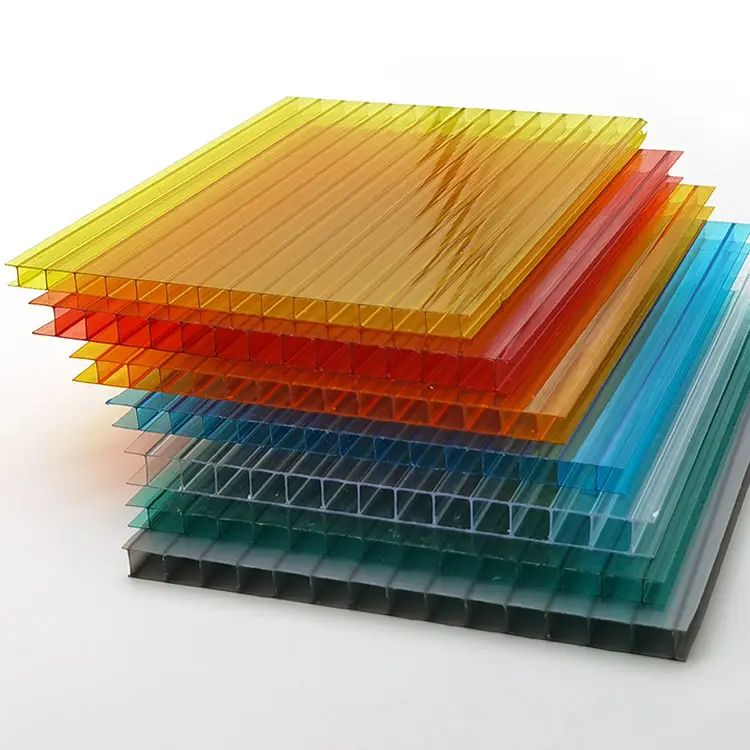

The multiwall polycarbonate is superior lightweight featuring a cellular structure and strong connection. It is super impact resistance, heat preservation and sound insulation that provides 50% or 70% more thermal insulation than glass. It is the best solution for home outdoor applications such as awning protection, pergolas roof.

which has outstanding physical , mechanical. electrical and thermal properties .Therefore. Polycarbonate Hollow Panels has the reputation of" king of transparent plastic" which has the advantages of good impact resistance. heat insulation ,sound insulation ,lighting, UV protection, flame retardant, etc. And Polycarbonate Hollow Panels is widely used for building roofing, skylight dome, public facilities skylight. multiwall Polycarbonate Hollow Panels blocks 99.9% UV rays with a UV coating layer and the lifespan lasts 15-20 years.

Polycarbonate Hollow Panels parameters

|

Product Name |

Polycarbonate Hollow Panels |

|

Place of Origin |

Shanghai |

|

Material |

100% Virgin polycartonate material |

|

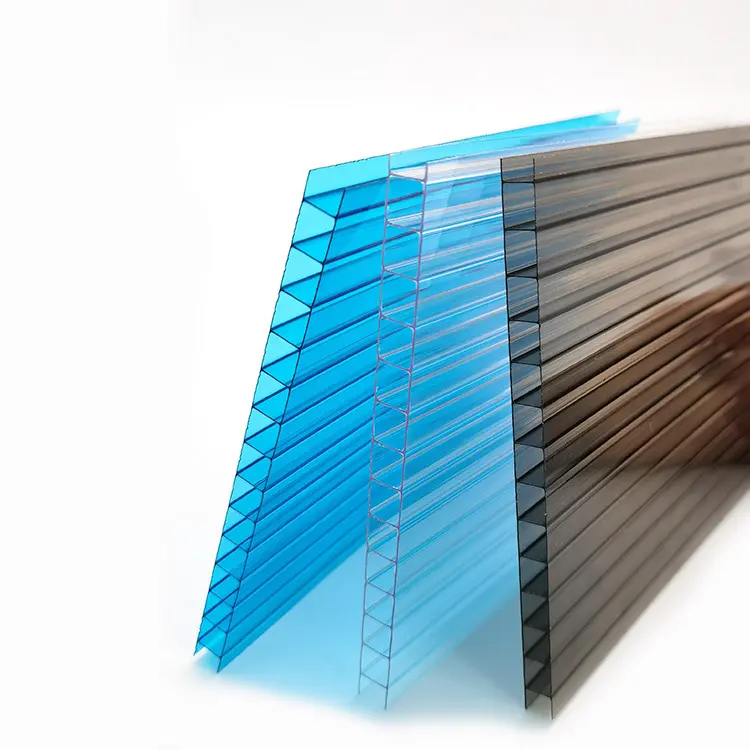

Colours |

Clear, bronze, blue, green, opal, gray or customized |

|

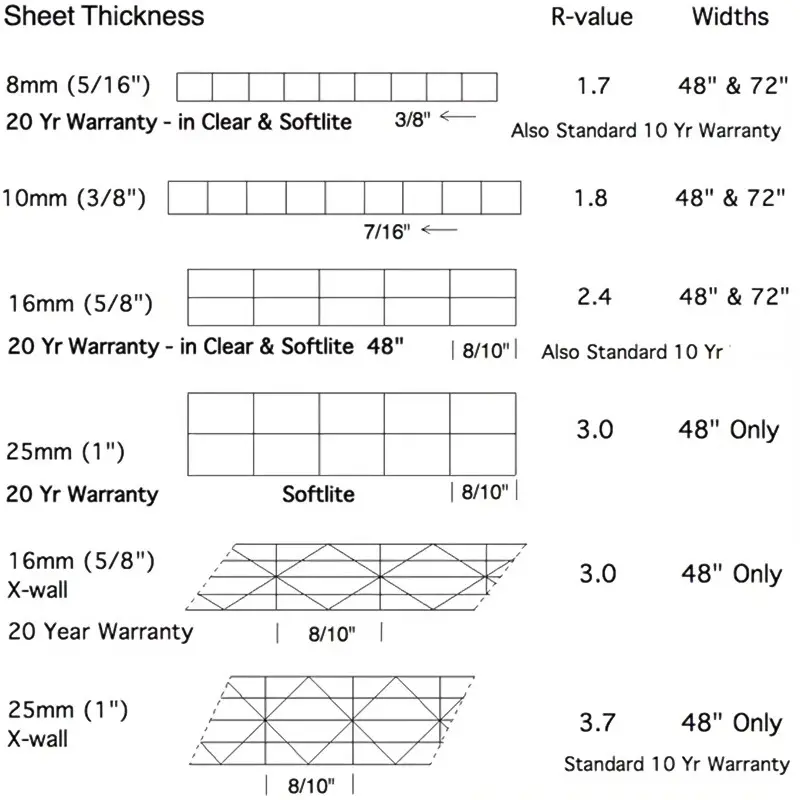

Thickness |

3-20 mm Polycarbonate hollow panel |

|

Width |

2.1m , 1.22m or customized |

|

Length |

5.8m/6m/11.8m/12m or customized |

|

Surface |

With 50 micron UV protection , heat resistance |

|

Retardant standard |

Grade B1 (GB Standard) Polycarbonate hollow panel |

|

Packaging |

Both sides with PE film, logo on the PE film. Customized package is available too. |

|

Delivery |

Within 7-10 working days once we received the deposit. |

|

UV protective layer |

50μm |

|

Softening temperature |

148°C |

|

Long-term operating temperature |

-40-120°C |

|

Elasticity modulus |

2400MPA(1mm/rain.ISO 527) |

|

Tensile yield stress |

63MPA(at yeild 50mm/min.lSO 527) |

|

Tensile strain |

6%(at yeild 50mm/min.lSO 527) |

|

Nominal tensile strain at break |

>50%(at break 50mm/min.lSO 527) |

|

lmpact strength of simply-supportedbeam method at 23°C |

NB(ISO 179/leU) |

|

Impact strength of simply-supportedbeam method at 30°C |

NB(ISO 179/leU) |

|

lmpact strength ofcantilever beam method (notch) at 23°C |

80ki/m2(1S0 180/4A) |

|

lmpact strength ofcantilever beam method (notch) at 30°C |

20ki/m3(lSO 180/4A) |

|

Fireproof performance |

GB8624-1997 B1 |

POLYCARBONATE HOLLOW PANELS advantages

POLYCARBONATE PANELS application

● Unusual decorations, corridors and pavilions in gardens and recreational and rest places.

● Interior and exterior decorations of commercial buildings, and curtain walls of the modern urban buildings.

● The transparent containers, front wind shields of motorcycles, airplanes, trains, ships, vehicles, motor boats, sub marines.

● Telephone booths, street name plates and sign boards.

● Instrument and war industries - windscreens, army shields.

● Walls, roofs, windows, screens and other high quality indoor decoration materials.

● Sound insulation shields on express ways and city hour highways.

● Agriculture greenhouses and sheds.

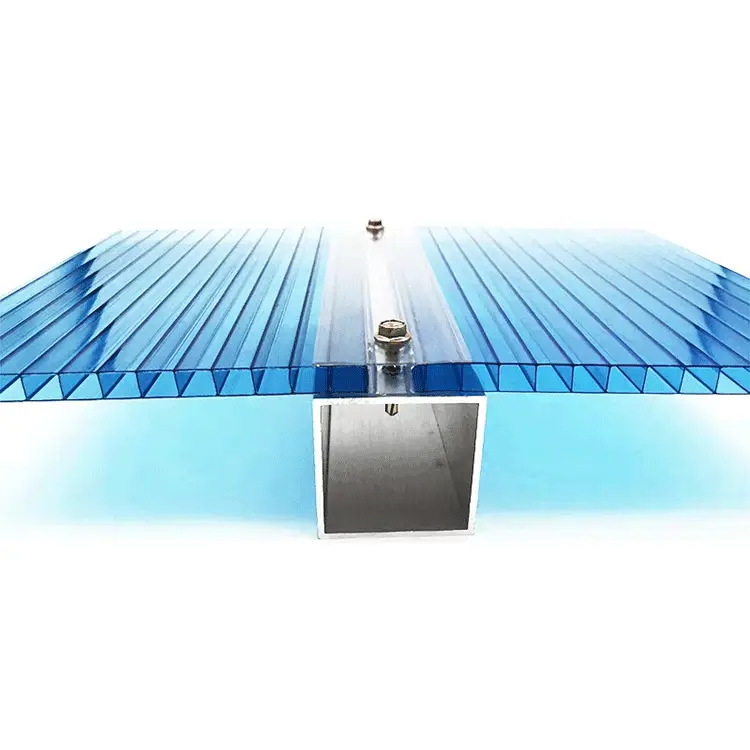

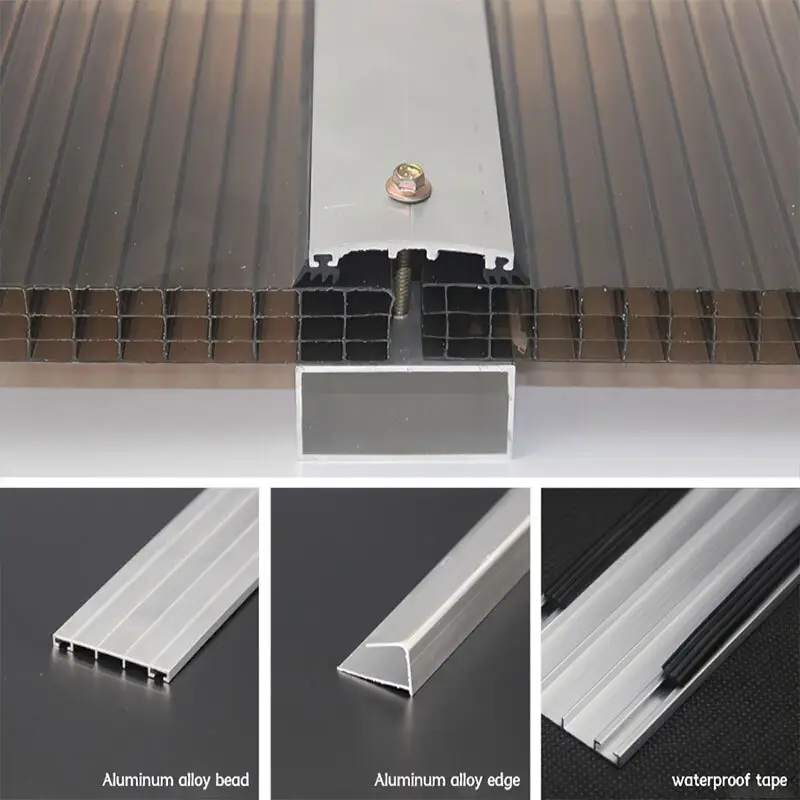

POLYCARBONATE panels INSTALLATION

MCLpanel Polycarbonate Hollow panels is produced with a protective PE film both sides which should be kept on until the panel is fastened. The UV protected side(with fonts) is to be faced towards the sun . Remove all protective film immediately after installation.

Make sure the support structure is clean and dry. Expand the hole before installation,The hole diameter is 1.5 times the diameter of the screw. Must leave a gap of at least 5mm in between panels for thermal expansion and contraction.

Use a new or sharply ground steel or carbide drill bit to drill the hole. When drilling edges all holes must be at least 40mm from the edge of the panel.

Why choose us?

ABOUT MCLPANEL

WHY CHOOSE MCLPANEL?

Tips on polycarbonate panel

Knowing more about polycarbonate panel can help you use it longer.

FAQ

Company Advantage

• According to the modern enterprise management system, Mclpanel established an elite team with rich industry experience in production, processing, and sales.

• After years of development, Mclpanel has a strong economic strength and gains high credibility in the industry.

• Mclpanel possesses advantageous geographical position transportation here is convenient for the direct buses and nearby subways.

Hurry up! Contact Mclpanel and get free samples of new kinds of Polycarbonate Solid Sheets,Polycarbanote Hollow Sheets,U-Lock Polycarbonate,plug in polycarbonate sheet,Plastic Processing,Acrylic Plexiglass Sheet.