Focus on PC/PMMA sheet production and processing jason@mclsheet.com +86-187 0196 0126

Worldwide Polycarbonate Roof Supplier for House

Product details of the polycarbonate roof

Product Information

Mclpanel polycarbonate roof presents a perfect marketing effect with its appealing design style. Its design comes out from our designers who have put their efforts on the innovation of design day-and-night. Our quality experts test this product on different parameters, so as to maintain the quality. Strict quality assurance is under the control in Mclpanel to ensure the quality.

Product Description

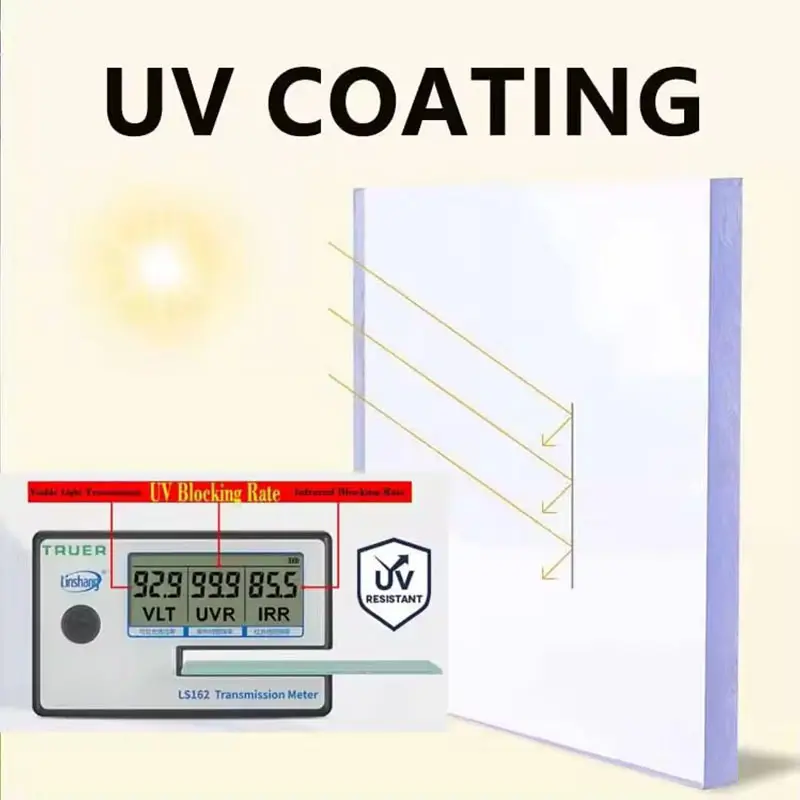

At our manufacturing facility, we offer a diverse range of Embossed polycarbonate solid sheets products, including options with thicknesses of 2mm - 20mm. These PC panels are engineered to provide exceptional optical clarity and light transmission, making them well-suited for a wide variety of applications.

Key Characteristics of Embossed Polycarbonate Solid Sheets:

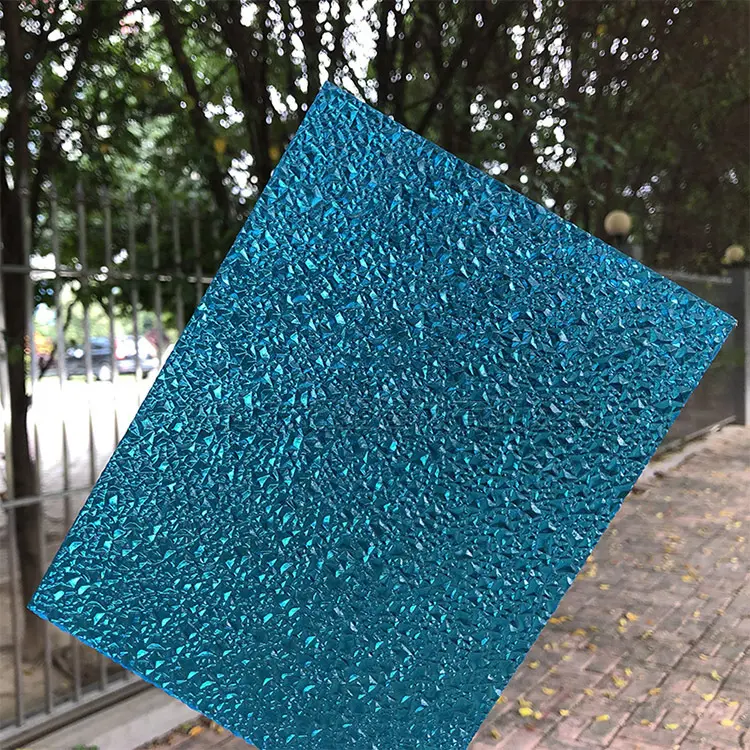

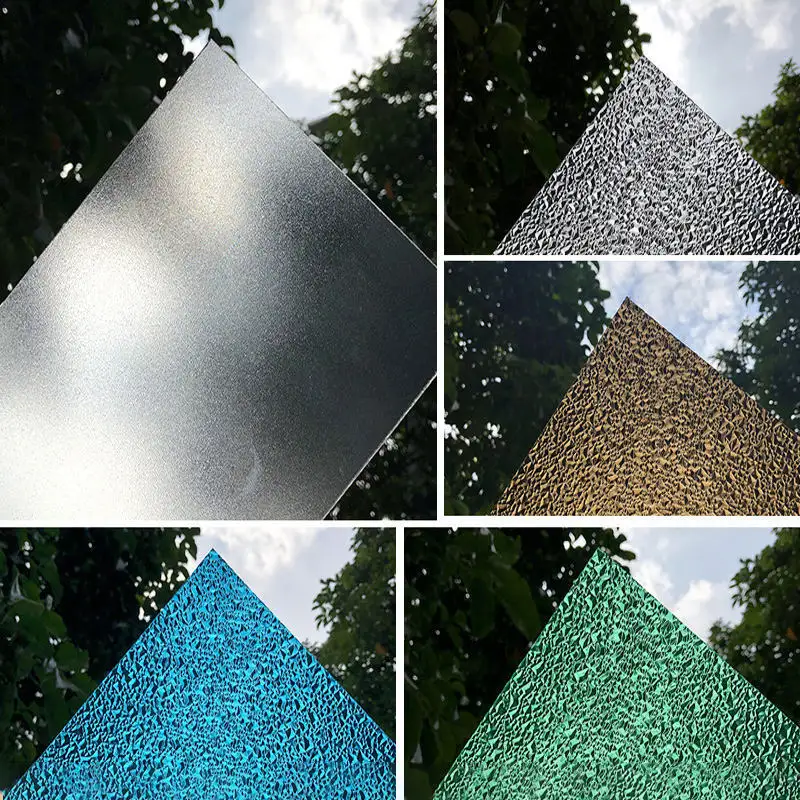

Surface Textures and Patterns:

The surface of these solid sheets is embossed with a variety of patterns and textures, ranging from simple linear designs to more complex and intricate geometrical motifs.

These surface treatments are integrated during the manufacturing process, creating a visually distinctive and aesthetically appealing appearance.

Improved Slip Resistance:

The embossed surface texture of the polycarbonate solid sheets can significantly enhance slip resistance, making them a safer choice for applications where traction is crucial, such as in flooring or outdoor walkways.

This feature is particularly beneficial in wet or high-traffic environments, improving safety and reducing the risk of accidents.

Enhanced Light Diffusion:

The embossed patterns on the polycarbonate solid sheets can help to diffuse and scatter light, creating a more even and diffused illumination.

This makes them an excellent choice for lighting applications, such as skylights, light fixtures, and diffusers, where a soft, uniform lighting effect is desired.

Increased Privacy and Obscuration:

Certain embossed patterns can provide a degree of obscuration or privacy, reducing visibility through the polycarbonate solid sheet while still allowing for the transmission of light.

Solid polycarbonate sheets offer a versatile and durable solution for a wide range of applications, from architectural elements to industrial and commercial settings. Their combination of impact resistance, optical clarity, and design flexibility make them a valuable choice for designers, architects, and manufacturers seeking a high-performance building material.

Regardless of the thickness, our transparent PC sheets are manufactured to the highest standards, leveraging advanced production techniques to deliver materials with consistent quality and optical properties. Customers across diverse industries rely on these thin-profile polycarbonate solutions to elevate their designs and enhance the visual experience for end-users.

product parameters

|

Characterics |

Unit |

Data |

|

Impact strength |

J/m |

88-92 |

|

Light transmission |

% |

50 |

|

Specify Gravity |

g/m |

1.2 |

|

Elongation at break |

% |

≥130 |

|

Coefficient thermal expansion |

mm/m℃ |

0.065 |

|

Service temperature |

℃ |

-40℃~+120℃ |

|

Heat conductively |

W/m²℃ |

2.3-3.9 |

|

Flexural strength |

N/mm² |

100 |

|

Modulus of elasticity |

Mpa |

2400 |

|

Tensile strength |

N/mm² |

≥60 |

|

Soundproof index |

dB |

35 decibel decrease for 6mm solid sheet |

Product advantages

Product application

1) Unusual decorations, corridors and pavilions in gardens and recreational and rest places;

2) Interior and exterior decorations of commercial buildings, and curtain walls of the modern urban buildings;

3) The transparent containers, front wind shields of motorcycles, airplanes, trains, ships, vehicles, motor boats, sub marines;

4) Telephone booths, street name plates and sign boards;

5) Instrument and war industries - windscreens, army shields

6) Walls, roofs, windows, screens and other high quality indoor decoration materials;

7) Sound insulation shields on express ways and city hour highways;

8) Agriculture greenhouses and sheds;

COLOR

Clear/Transparent:

- This is the most common and popular option, offering maximum light transmission and optical clarity

- Transparent PC sheets are widely used for glazing, skylights, and other applications where clear visibility is desired

Tinted:

- Polycarbonate sheets can be produced with various tinted or colored options

- Common tint colors include smoke gray, bronze, blue, green, and amber

- Tinted PC sheets can be used to provide glare reduction, enhanced privacy, or specific aesthetic effects

Opal/Diffused:

- Opal or diffused polycarbonate sheets have a translucent, milky appearance

- They provide a soft, even light diffusion, reducing direct glare and hot spots

- Opal PC sheets are often used for lighting fixtures, partitions, and other applications requiring diffused illumination

PRODUCT INSTALLTION

Prepare the Installation Area:

Gather the Necessary Tools and Materials:

Install the Supporting Structure:

Cut and Prepare the Polycarbonate Sheets:

Why choose us?

ABOUT MCLPANEL

Our advantage

FAQ

Company Advantage

• Since the inception in our company has been adhering to the business philosophy of 'quality determines sales, conscience determines fate' for years. And, we have been in a steady state of development in different economic storms.

• Our company thinks highly of talents management and scientific and technological innovation. Therefore, our talents team is of high technical level and strong management ability.

• Mclpanel sincerely provides quality and comprehensive services for the vast number of customers. We receive unanimous acclaim from customers.

• The sales network of our products has gradually been expanded from the province to all parts of the country. Therefore, the social influence of our company has been greatly improved.

We are committed to providing customers with quality products. We sincerely welcome customers with needs to contact us, and look forward to establishing a long-term friendly relation with you!