Focus on PC/PMMA sheet production and processing jason@mclsheet.com +86-187 0196 0126

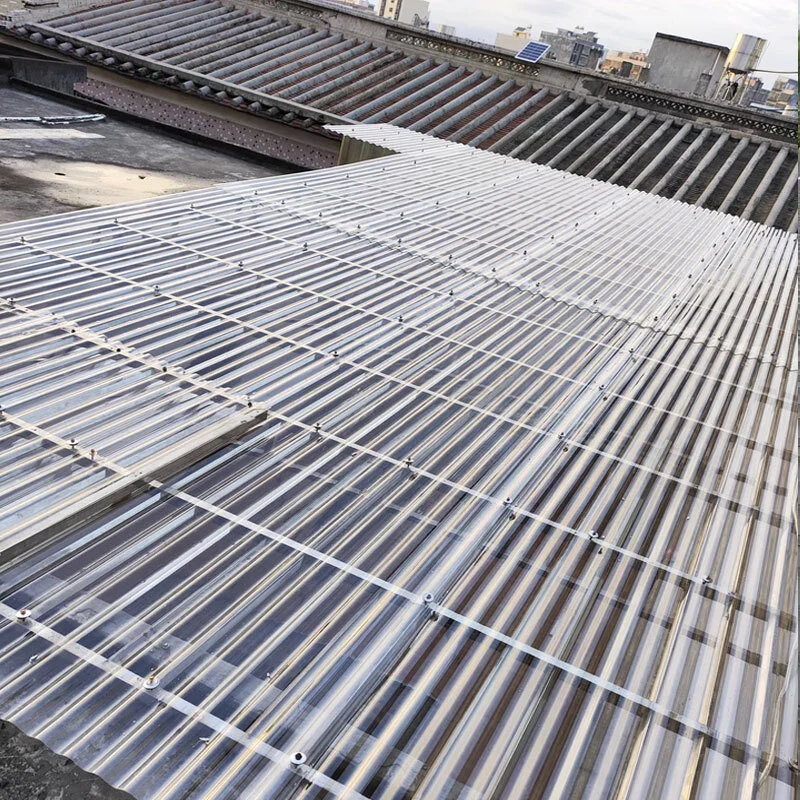

Transparen Corrugated Polycarbonate Sheet With UV Protected For Greenhouse

Solid corrugated polycarbonate sheets are a popular choice for various applications due to their unique combination of strength, durability, and lightweight properties.

Product Name: Solid corrugated polycarbonate sheets

Thickness: 0.8mm,1.0mm,1.2mm,1.5mm,2.0mm,2.5mm

Width: 840mm/930mm/1110mm, Custom

Length: Any length, can be cut according to customer needs

Color: Clear, opal, blue, green, grey, brown, yellow, red, black. etc

Warranty: 10 years

Product Description

Solid corrugated polycarbonate sheets are a popular choice for various applications due to their unique combination of strength, durability, and lightweight properties. Here’s an overview of their features and common uses:

Key Features:

Durability: These sheets are highly resistant to impact, making them suitable for both indoor and outdoor applications.

Lightweight: Compared to glass, solid corrugated polycarbonate is much lighter, facilitating easier handling and installation.

UV Resistance: Many sheets are treated with UV protection, which helps prevent yellowing and degradation from sun exposure.

Thermal Insulation: The corrugated structure provides good insulation properties, helping to maintain temperature stability in buildings and structures.

Easy to Fabricate: They can be easily cut, drilled, and shaped, allowing for customization in various projects.

Common Applications:

Roofing: Ideal for carports, greenhouses, and patio covers, providing shelter while allowing light transmission.

These characteristics and applications make solid corrugated polycarbonate sheets a popular choice in many industries. If you need more specific information or have particular applications in mind, feel free to ask!

product parameters

|

Characterics |

Unit |

Data |

|

Impact strength |

J/m |

88-92 |

|

Light transmission |

% |

50 |

|

Specify Gravity |

g/m |

1.2 |

|

Elongation at break |

% |

≥130 |

|

UV Coating |

Um |

50 |

|

Service temperature |

℃ |

-40℃~+120℃ |

|

Heat conductively |

W/m²℃ |

2.3-3.9 |

|

Flexural strength |

N/mm² |

100 |

|

Modulus of elasticity |

Mpa |

2400 |

|

Tensile strength |

N/mm² |

≥60 |

|

Soundproof index |

dB |

35 decibel decrease for 6mm solid sheet |

CUSTOM SIZE AND THICKNESS

Custom sizes available to fit your specific needs.

Width (mm) | 670 | 830 | 900 | 970 | 1080 | 1110 |

Coverage (mm) | 600 | 760 | 840 | 900 | 1000 | 1025 |

PRODUCT ADVANTAGE

1) Light transmitance rate: up to 12%-88%, according to different colors

2) Ultraviolet ray filter rate: 99%,with ultraviolet-resistant co-extruded film on the surface

3) Impact strength: 250--280 times of the ordinary glass; 2 times of toughened glass; 20--30 times of PMMA sheet

4) Fire retardance: Grade B2, according to national GB8625-88 test

5) Sound insulation: can effectively resist the noise spread

6) Temperature resistance: not deform from -40 degrees Celsius to +120 degrees Celsius

7) Light weight: with density of 1.20g/cm³, easy to handle and drill; convenient for construction and procession

COLOR

Clear/Transparent:

- This is the most common and popular option, offering maximum light transmission and optical clarity

- Transparent PC sheets are widely used for glazing, skylights, and other applications where clear visibility is desired

Tinted:

- Polycarbonate sheets can be produced with various tinted or colored options

- Common tint colors include smoke gray, bronze, blue, green, and amber

- Tinted PC sheets can be used to provide glare reduction, enhanced privacy, or specific aesthetic effects

Opal/Diffused:

- Opal or diffused polycarbonate sheets have a translucent, milky appearance

- They provide a soft, even light diffusion, reducing direct glare and hot spots

- Opal PC sheets are often used for lighting fixtures, partitions, and other applications requiring diffused illumination

PRODUCT INSTALLTION

The specific method is as follows:

1.The overlap method is used as follows: Usually the overlap length should be the length between wavelengths, which is about 45mm

2. Fix with screws, one screw every 30-40 cm: the diameter of the fastening nail head should be greater than 1.5 times the diameter of the nail rod and waterproof glue should be applied; and do not let the nail head press directly on the board surface to reduce pressure.

Why choose us?

ABOUT MCLPANEL

Our advantage

FAQ