Focus on PC/PMMA sheet production and processing jason@mclsheet.com +86-187 0196 0126

Hot Sale Solid Polycarbonate Sheet Thickness for Roofing Series Fast Delivery

Product details of the solid polycarbonate sheet thickness for roofing

Product Introduction

The persistent team of Mclpanel has also been working hardly on the design of solid polycarbonate sheet thickness for roofing. This product complies with industrial quality standards. The product meets with customer's specific application need.

Product Description

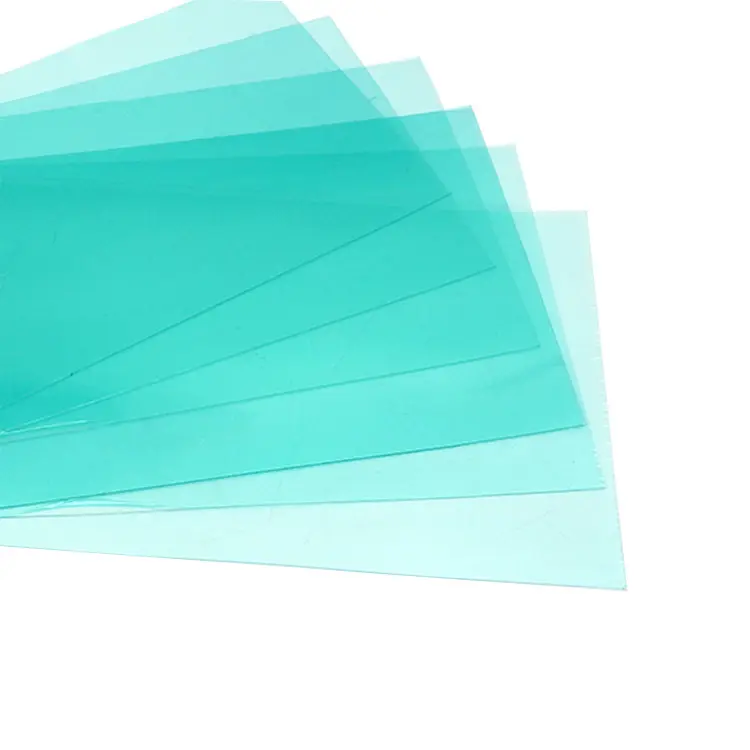

Unleashing the Potential of Polycarbonate Thin Films

At our advanced manufacturing facility, we specialize in the production of high-performance polycarbonate (PC) thin films. These versatile materials, available in thicknesses ranging from 0.05mm to 0.5mm, offer a unique combination of optical clarity, mechanical durability, and dimensional stability.

Polycarbonate thin films excel in applications where transparency, flexibility, and impact resistance are critical requirements. Their lightweight yet robust nature makes them an ideal choice for protecting delicate electronic displays, enhancing the visual appeal of consumer products, and providing protective shielding in architectural glazing.

Our proprietary manufacturing processes ensure the PC thin films maintain exceptional optical properties, with high light transmittance and minimal distortion. This clarity, coupled with the films' inherent flexibility, allows them to be seamlessly integrated into a wide range of products and design solutions.

Beyond their optical performance, the polycarbonate thin films also boast impressive mechanical characteristics. They exhibit superior impact resistance, scratch resistance, and dimensional stability, enabling them to withstand the rigors of everyday use without compromising their visual integrity.

Customers across diverse industries, from electronics to transportation, rely on our high-quality polycarbonate thin film solutions to elevate their products, enhance user experiences, and meet the ever-evolving demands of the market.

product parameters

|

Characterics |

Unit |

Data |

|

Impact strength |

J/m |

88-92 |

|

Light transmission |

% |

50 |

|

Specify Gravity |

g/m |

1.2 |

|

Elongation at break |

% |

≥130 |

|

Coefficient thermal expansion |

mm/m℃ |

0.065 |

|

Service temperature |

℃ |

-40℃~+120℃ |

|

Heat conductively |

W/m²℃ |

2.3-3.9 |

|

Flexural strength |

N/mm² |

100 |

|

Modulus of elasticity |

Mpa |

2400 |

|

Tensile strength |

N/mm² |

≥60 |

|

Soundproof index |

dB |

35 decibel decrease for 6mm solid sheet |

Product advantages

Product application

● Display and Touchscreens: Polycarbonate films are used in electronic displays, including LCDs, LED screens, and touchscreens.

● Packaging: Polycarbonate films are used in packaging applications such as blister packs, clamshells, and protective covers.

● Automotive: Polycarbonate films are utilized in the automotive industry for various purposes.

● Labels and Nameplates: Polycarbonate films are used for creating durable labels, nameplates, and graphic overlays.

● Electrical and Electronics: Polycarbonate films find extensive use in electrical and electronic applications.

● Industrial Equipment: Polycarbonate films are employed in various industrial equipment and machinery.

● Solar Panels: Polycarbonate films with UV-resistant properties are used in solar panel applications.

● Medical Devices: Polycarbonate films are used in medical device applications, including equipment housings, touch-sensitive controls, and disposable medical products.

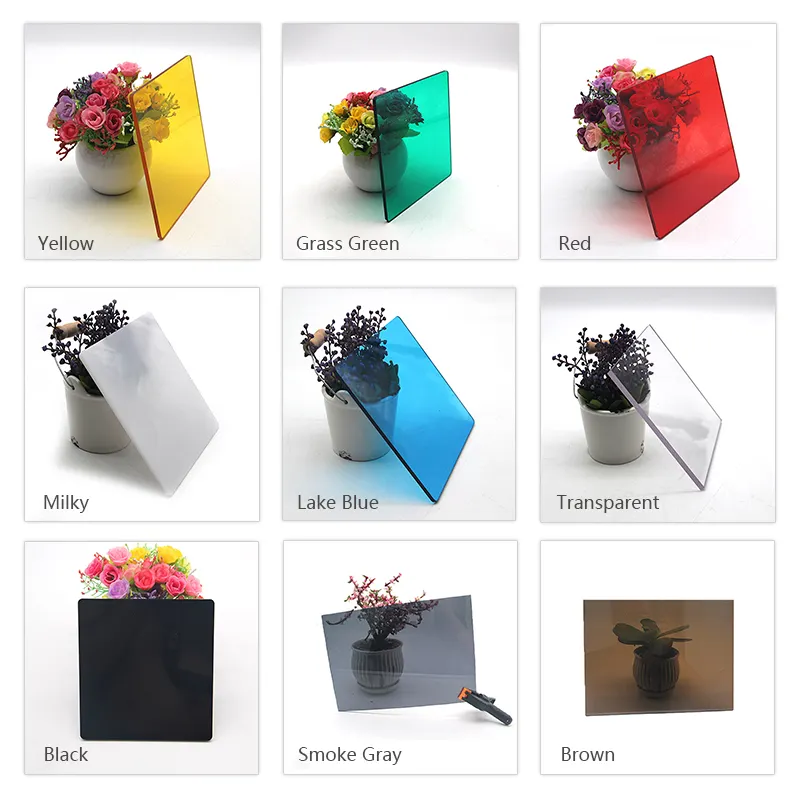

product color

Clear/Transparent:

This is the most common and popular option, offering maximum light transmission and optical clarity

Transparent PC films are widely used for display protection, shielding, and other applications where clarity is essential

Tinted:

Polycarbonate films can be produced with various tinted or colored options

Common tint colors include smoke, gray, bronze, blue, green, and amber

Tinted films can be used for applications that require glare reduction, enhanced privacy, or specific aesthetic preferences

Why choose us?

ABOUT MCLPANEL

Our advantage

FAQ

Company Advantage

• We will serve you with the best products and the best service!

• Formally established in our company has been committed to the research and development and innovation of the main products. After years' exploration and development, we have successfully developed a feature road that is in line with China's national conditions and suitable for our own situation.

• Our company actively explores product sales channels and establishes a sound marketing network. Our products are not only sold to many provinces and cities in China, but also exported to East Asia and South Asia.

• Our company is located in a superior geographical position. And we are enjoying abundant resources and convenient transportation. It is a good natural and human geographical environment.

Mclpanel's Polycarbonate Solid Sheets,Polycarbanote Hollow Sheets,U-Lock Polycarbonate,plug in polycarbonate sheet,Plastic Processing,Acrylic Plexiglass Sheet have excellent quality, favorable price and complete types and specifications. If you have any needs, please call our hotline to know more information!