Focus on PC/PMMA sheet production and processing jason@mclsheet.com +86-187 0196 0126

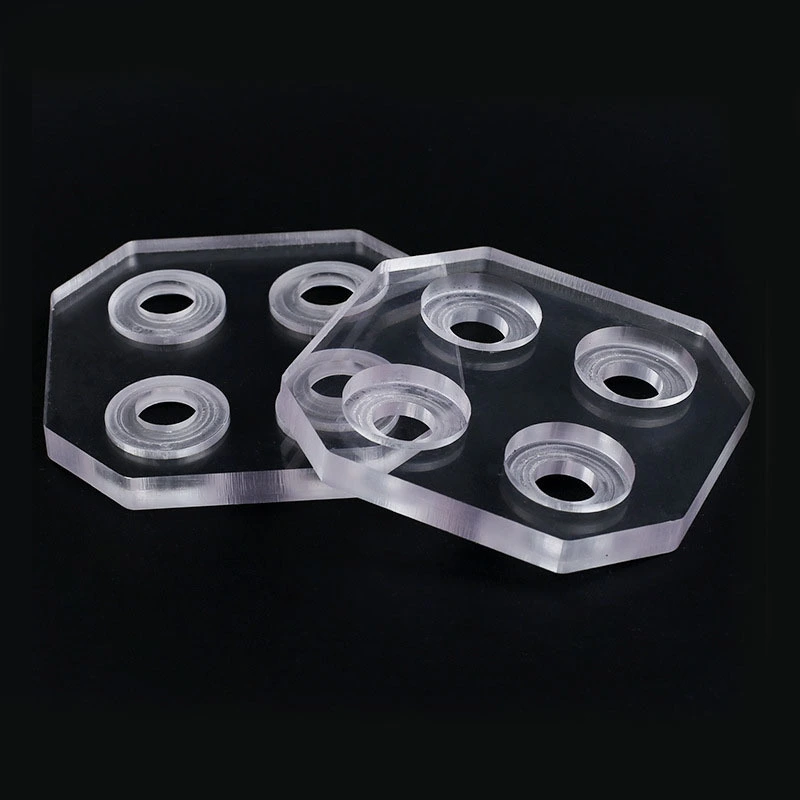

Custom acrylic polycarbonate milling components parts by machining agrooves slots

Acrylic milling and machining are essential fabrication techniques that allow for the precise shaping, cutting, and modification of acrylic materials. These processes leverage the capabilities of computer numerical control (CNC) machines and traditional milling equipment to create a wide range of custom acrylic components and parts.

Product Name: Acrylic/Polycarbonate milling/machining

Thickness: 1mm-20mm, customized

Width: 1000/1220/2000mm, custom

Length: 2000/2440mm, custom

Warranty: 10 years

Product Description

Acrylic/Polycarbonate milling and machining are essential fabrication techniques that allow for the precise shaping, cutting, and modification of acrylic materials. These processes leverage the capabilities of computer numerical control (CNC) machines and traditional milling equipment to create a wide range of custom acrylic components and parts.

Key Advantages of Acrylic/Polycarbonate Milling and Machining:

Design Flexibility:

Milling and machining techniques enable the creation of complex, intricate, and customized acrylic shapes, profiles, and features.

Designers and manufacturers can incorporate various design elements, such as holes, slots, grooves, and contoured surfaces, into the acrylic parts.

Precision and Accuracy:

CNC milling machines, in particular, offer exceptional precision and repeatability, ensuring that each acrylic part meets the desired specifications.

The computer-controlled nature of CNC milling allows for the production of highly accurate and consistent acrylic components.

Material Versatility:

Acrylic milling and machining techniques can be applied to a variety of acrylic substrates, including cast, extruded, and cell-cast acrylic sheets, as well as custom-made acrylic shapes and forms.

CNC milling machines can operate with minimal human intervention, increasing the efficiency and throughput of the manufacturing process.

This automation allows for the mass production of custom acrylic parts without compromising quality or consistency.

Dimensional Stability:

Acrylic is a dimensionally stable material, and the milling and machining processes do not significantly alter its inherent properties.

This ensures that the final acrylic parts maintain their dimensions and structural integrity over time.

product parameters

|

Material |

Acrylic or polycarbonate |

|

Machining crafts |

Acrylic milling/machining |

|

Color |

Transparent, white, opal, black, red, green, blue, yellow, etc. OEM color OK |

|

Standard size |

Based on your specific drawing with customized shape/size ... |

|

Certificate |

CE, SGS, DE, and ISO 9001 |

|

Equipment |

Imported glass models (from Pilkington Glass in U. K. |

|

MOQ |

2 tons, can be mixed with colors/sizes/thickness |

|

Delivery |

10-25 days |

Advantages

product Advantages

Product application

Advertising boards and signage production: Acrylic advertising boards and signs have the advantages of high transparency, bright colors, and good processability, and are widely used in indoor and outdoor advertising, corporate image display, and other fields.

Home decoration product manufacturing: Acrylic materials can be made into decorative items with unique shapes, such as lighting fixtures, vases, photo frames, etc., which are creative and enhance the aesthetics of the home.

Handicraft production: Acrylic materials are easy to engrave and shape, and can be used to make various exquisite crafts, such as trophies, medals, souvenirs, etc.

Display product manufacturing: Acrylic materials have high transparency and stable structure, suitable for making various display products, such as display cabinets, racks, and display stands.

Medical device manufacturing: Acrylic has biocompatibility and disinfection properties, and can be used to make disposable medical devices and nursing equipment.

Electronic product housing manufacturing: Acrylic housings have the advantages of light weight, wear resistance, and easy processing, and are widely used in the housings and protective cases of electronic products such as mobile phones and tablets.

Machining Parameters:

Use carbide-tipped tools designed for plastics. Avoid high-speed steel tools.

Spindle speeds around 10,000-20,000 RPM work well for polycarbonate.

Feed rates of 300-600 mm/min are typical.

Use low depth of cut, around 0.1-0.5 mm, to avoid chipping or cracking.

Apply a coolant or lubricant to keep the material from overheating.

Design Creation: The desired design is created using CAD software, ensuring the desired dimensions, patterns, and details are accurately specified.

CNC Programming: The CAD design is translated into machine-readable code, which is then loaded into the CNC engraving machine's control system.

Engraving: The CNC machine precisely follows the programmed instructions, using specialized cutting tools or engraving bits to remove material from the acrylic surface, creating the desired design.

Finishing: Depending on the application, the engraved acrylic piece may undergo additional finishing steps, such as polishing, cleaning, or the application of protective coatings.

COMMON PROCESSING

Acrylic/polycarbonate is a versatile material that can be processed using a variety of common manufacturing techniques. Here are some of the most common acrylic fabrication and processing methods:

Cutting and Shaping:

Laser Cutting: Precise and clean cuts can be achieved using computer-controlled laser cutting machines.

CNC Machining: Computer Numerical Control (CNC) milling and routing machines can be used to cut complex shapes and profiles in Acrylic/polycarbonate.

Bonding and Joining:

Adhesive Bonding: Acrylic/polycarbonate can be joined using various adhesives, such as cyanoacrylate (super glue), epoxy, or acrylic-based cements.

Solvent Bonding: Solvents like methylene chloride or acrylic-based cements can be used to chemically weld acrylic parts together.

Bending and Forming:

Thermoforming: Acrylic/polycarbonate sheets can be heated and formed into various shapes using molds or bending jigs.

Cold Bending: Acrylic/polycarbonate can be bent and shaped at room temperature, particularly for simple curves and angles.

Flame Bending: Carefully applying a flame to the Acrylic/polycarbonate surface can soften the material, allowing it to be bent and shaped.

Printing and Decoration:

Screen Printing: Acrylic/polycarbonate sheets can be screen printed with various inks and graphics to add visual interest or branding.

Digital Printing: Wide-format digital printers can be used to directly print images, text, or graphics directly onto acrylic surfaces.

Why choose us?

ABOUT MCLPANEL

Our advantage

FAQ